Treatment method for regulating and controlling morphology and particle size of oxysulfide fluorescent powder through laser irradiation

A technology of laser irradiation and sulfur oxides, applied in chemical instruments and methods, nano optics, luminescent materials, etc., can solve the problems of not being able to obtain pure, high-quality crystalline sulfur oxide phosphors, achieve enhanced luminescence performance, and avoid Effects of agglomeration and enhancement of fluorescence properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

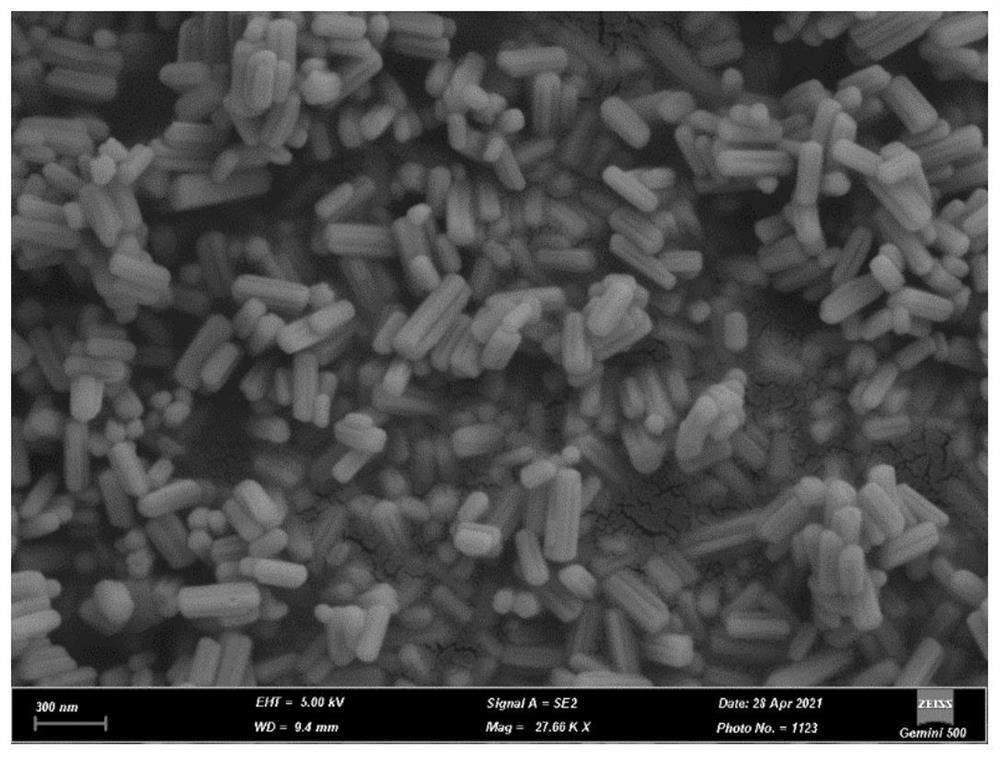

[0045] Dissolve 0.724g of gadolinium oxide and 0.0374g of tetraterbium heptoxide in 1.95mL and 1mL of concentrated nitric acid respectively, stir at 45°C, add 15mL of ethylene glycol and 10mL of ethanol mixture, and then Slowly add 2gPVP. After the PVP was completely dissolved, 1.1 g of thiourea was dissolved in 10 mL of ethanol at 60° C. and added to the prepared solution. At this time, the acidity of the solution was very strong, and a 2mol / L NaOH solution was prepared and added thereto until the pH of the solution was 12. After magnetic stirring for 1 h, the solution was poured into a hydrothermal reaction kettle, and kept at 200° C. for 24 h. After the incubation, the solution was washed three times with ethanol and deionized water respectively. After washing, dry in a forced air drying oven at 60°C. Obtain the precursor; put the precursor into a crucible, and take another crucible filled with sublimed sulfur and place it at the air inlet of the tube furnace. The precu...

Embodiment 2

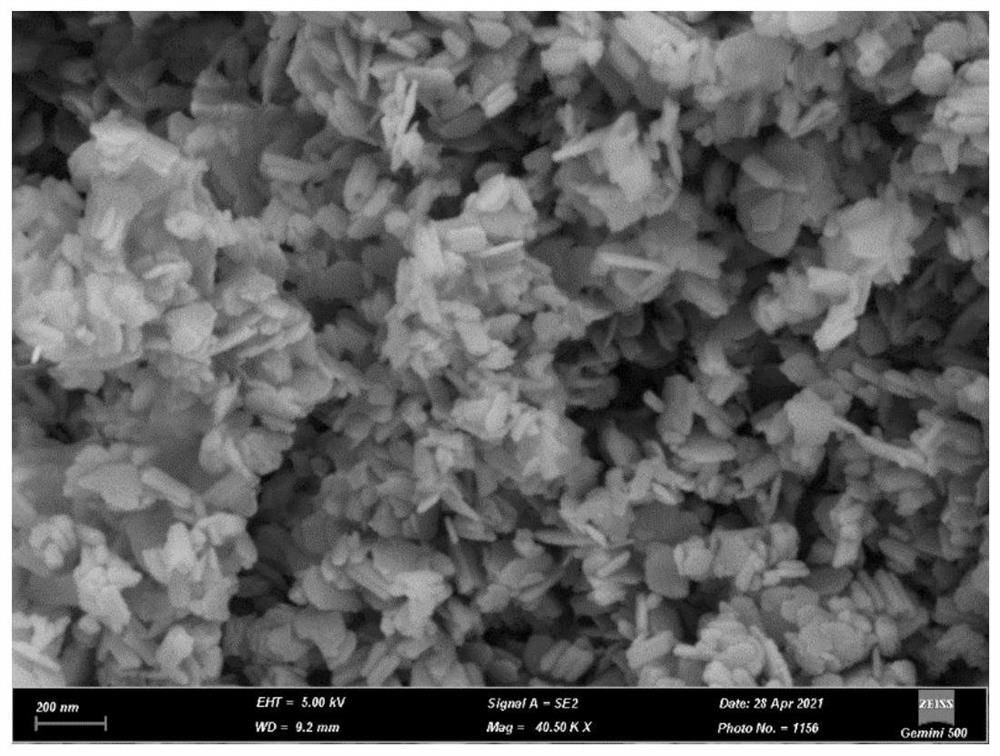

[0048] Take 0.452g of yttrium oxide and 0.0374g of tetrabium heptoxide and dissolve them in 1.95mL and 1mL of concentrated nitric acid respectively, and then prepare yttrium oxysulfide phosphor by the same method. Disperse the yttrium oxysulfide phosphor powder in ultrapure water to prepare a 1 mg / mL white suspension. The suspension was magnetically stirred at a rate of 500r / min, and while the suspension was magnetically stirred, a pulsed laser with a wavelength of 532nm, a pulse width of 8ns, a single pulse energy of 400mJ, and a pulse frequency of 10Hz was used to The fluorescent powder suspension was irradiated for 10 minutes, and then centrifuged at a speed of 10,000 rpm, and the precipitate obtained by centrifugation was washed three times with ultrapure water, and then dried in a blast drying oven at 60°C. Thus, the sulfur oxide cathodic ray phosphor whose morphology and size can be regulated by laser irradiation is obtained.

Embodiment 3

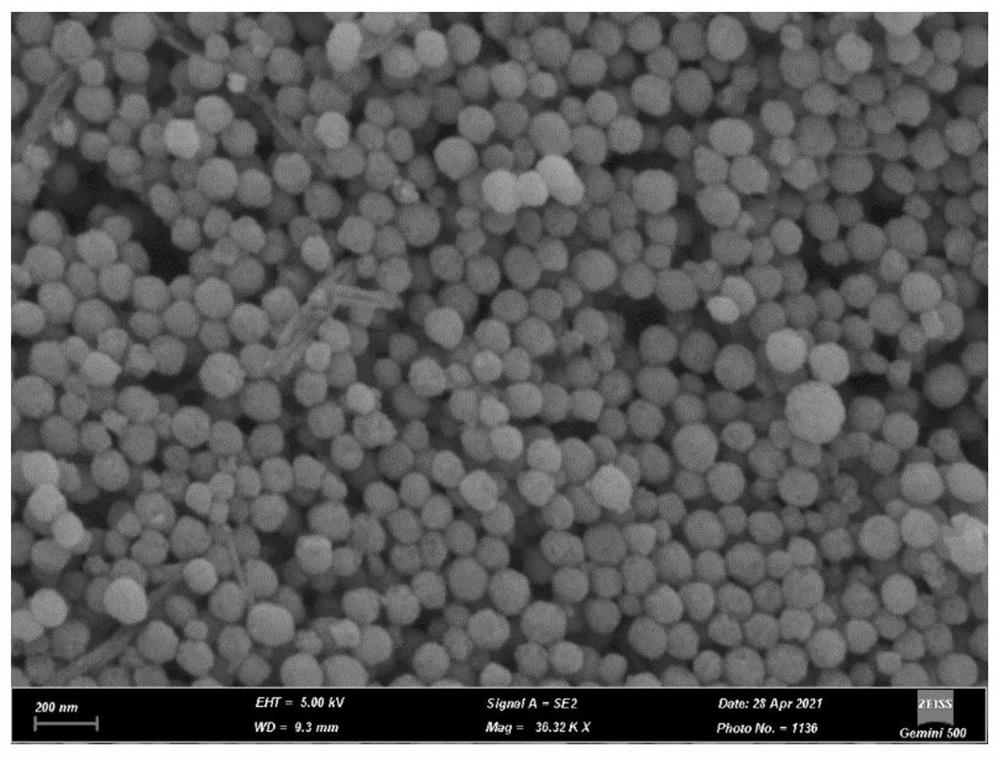

[0050] 0.838g of lutetium oxide and 0.0086g of cerium oxide were dissolved in 1.95mL and 1mL of concentrated nitric acid respectively, and then the lutetium oxysulfide phosphor was prepared by the same method. Disperse lutetium oxysulfide phosphor powder in ethylene glycol to prepare a 1 mg / mL white suspension. The suspension was magnetically stirred at a rate of 500r / min, and while the suspension was magnetically stirred, a pulsed laser with a wavelength of 532nm, a pulse width of 8ns, a single pulse energy of 400mJ, and a pulse frequency of 10Hz was used to The fluorescent powder suspension was irradiated for 10 minutes, and then centrifuged at a speed of 10,000 rpm, and the precipitate obtained by centrifugation was washed three times with ultrapure water, and then dried in a blast drying oven at 60°C. Thus, the sulfur oxide cathodic ray phosphor whose morphology and size can be regulated by laser irradiation is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com