Method for preparing small-grain Y-type molecular sieve

A molecular sieve and small-grain technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as poor thermal and hydrothermal stability, high crystallinity, and complete structure, and achieve stability Good properties, high crystallinity, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

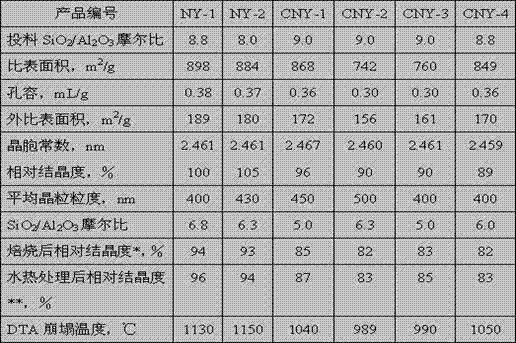

Embodiment 1

[0045] This embodiment is to prepare raw material small grain NaY molecular sieve

[0046] Preparation of NY-1

[0047] (1) Preparation of guiding agent: Dissolve 8 g of sodium hydroxide solid in 80 g of water, add 2.5 g of sodium metaaluminate (Al 2 o 3 Content is 45wt%, Na 2 O content is 41wt%), then add 40g water glass (SiO 2 Content is 28wt%, Na 2 The O content is 8wt%), mixed evenly, and aged at 18° C. for 4 hours to prepare the directing agent.

[0048] (2) Preparation of amorphous silicon-aluminum precursor

[0049] Prepare solid sodium aluminate to a concentration of 0.3L for 100g A1 2 o 3 / L sodium aluminate working solution (a). Dilute the concentrated ammonia water with an appropriate amount of distilled water to obtain about 10wt% dilute ammonia water (b). SiO 2 28wt% sodium silicate solution, then diluted to 0.5L concentration is 140g SiO 2 / L sodium silicate working solution (c). Take a 5-liter steel reaction tank, add 0.5 liter of distilled water to t...

Embodiment 2

[0063] First, carry out alkali treatment on the raw material small-grain NaY molecular sieve, beat and mix 1000 grams of NY-1 with 5 L of NaOH solution with a concentration of 1 mol / L, and maintain the temperature of 80 ° C for 2 hours, filter and wash to the solution Close to neutrality; contact the filter cake with 10 liters of 0.5 mol / L ammonium nitrate aqueous solution, stir at 300 rpm, stir at 90°C for 1 hour, then filter molecular sieves, and leave a small sample for analysis of Na 2 O content; repeat the above operation until Na in the molecular sieve 2 The O content reached 2.5wt%, and the sample number after drying was NNY-1.

Embodiment 3

[0065] First, carry out alkali treatment on the raw material small-grain NaY molecular sieve, beat and mix 1000 grams of NY-2 with 5 L of KOH solution with a concentration of 0.8 mol / L, and keep stirring at 80°C for 2 hours, filter, and wash with water until the solution Close to neutral; contact the filter cake with 10 liters of 0.5 mol / L ammonium nitrate aqueous solution, stir at 300 rpm, stir at a constant temperature of 95 ° C for 1 hour, then filter molecular sieves, and leave a small sample for analysis of Na 2 O content; repeat the above operation until Na in the molecular sieve 2 The content of O reached 2.5wt%, and the number of the dried sample was NNY-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com