Industrial production method of icodextrin

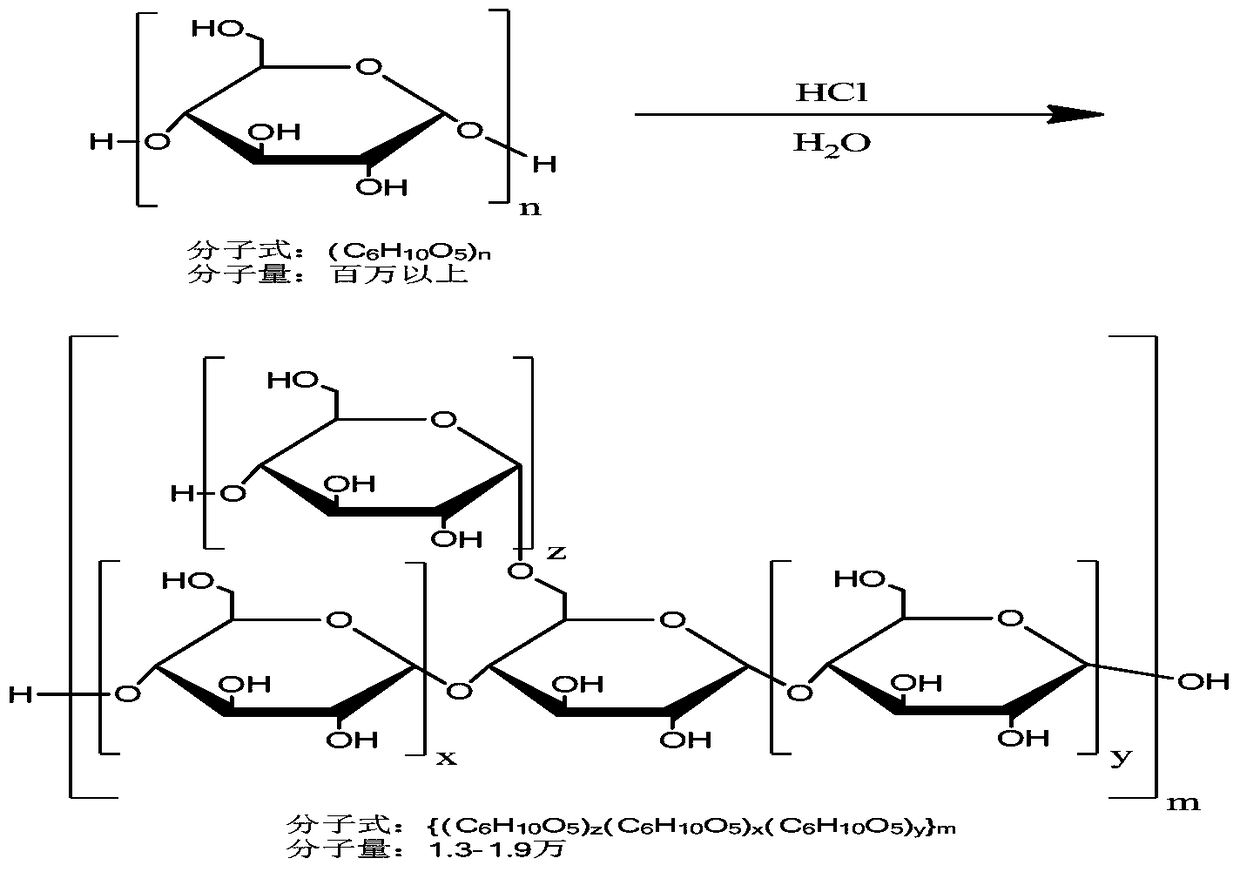

A production method, the technology of icodextrin, which is applied in the field of medicine, can solve the problems of increased production cost and poor quality, and achieve the effects of improving quality, concentrating the molecular weight of hydrolyzed products, and shortening the time-consuming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

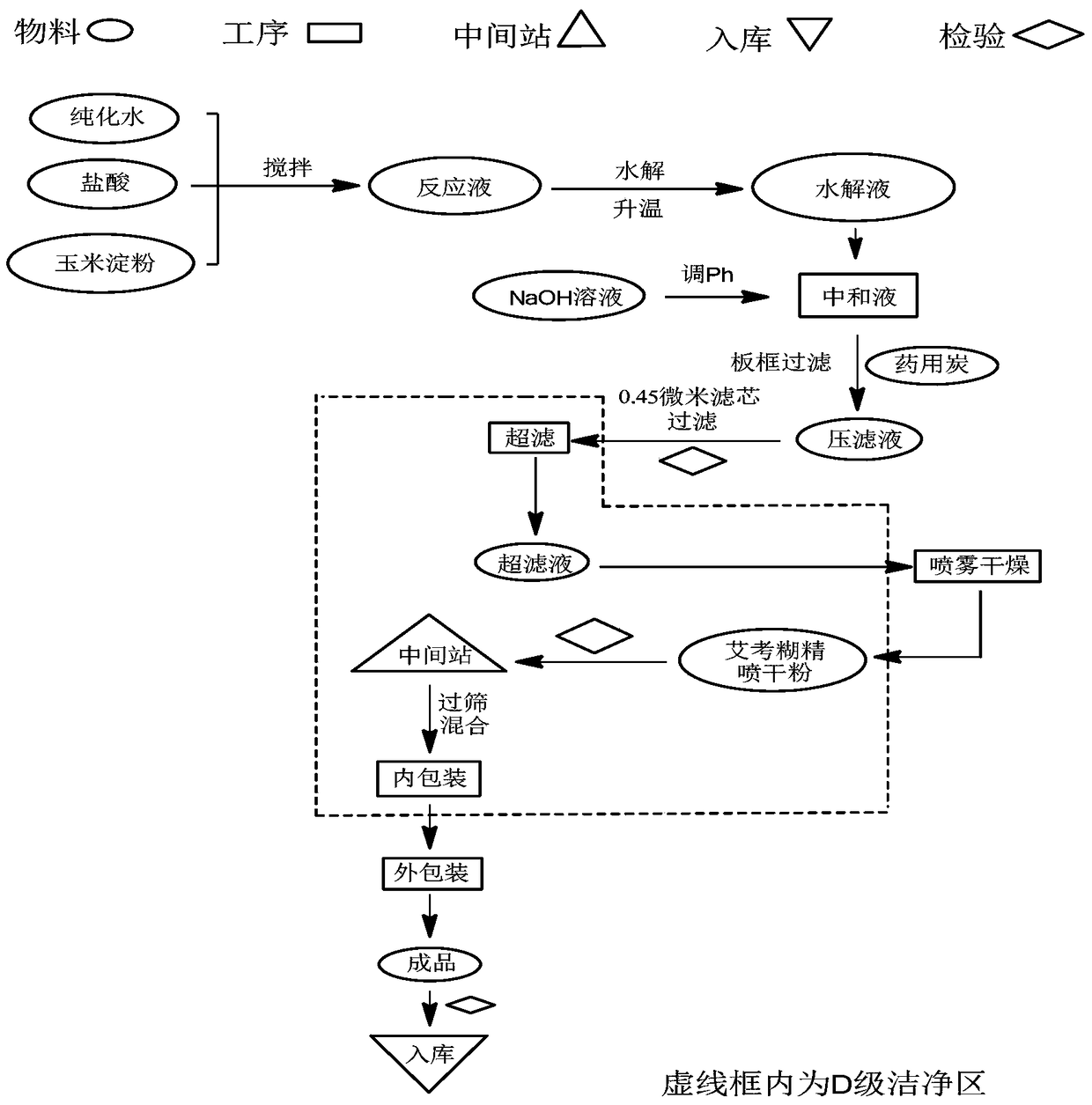

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 icodextrin of the present invention

[0030] a. prepare the acid solution whose concentration of hydrochloric acid is 0.6%;

[0031] b. Take 1000 parts by weight of the acid solution, add 400 parts by weight of cornstarch under stirring, the hydrolysis temperature is 90°C, and after 2 hours of hydrolysis reaction, adjust the pH to 6 to obtain a hydrolyzate;

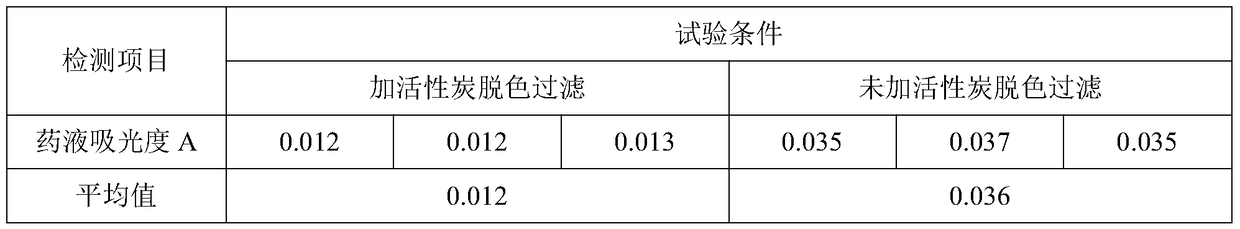

[0032] c. Cool the hydrolyzate prepared in step b to 55° C., add 12 parts by weight of activated carbon, decolorize for 0.5 hours, and filter after decolorization;

[0033] d. Ultrafiltration and drying of the filtrate prepared in step c, to obtain final product.

[0034] The obtained sample had a molecular weight (MW) of 16,800 Da and a water content of 3.86%.

Embodiment 2

[0035] Embodiment 2 The preparation of icodextrin of the present invention

[0036] a. prepare the acid solution whose concentration of hydrochloric acid is 0.9%;

[0037] b. Take 1000 parts by weight of the acid solution, add 450 parts by weight of cornstarch under stirring, and the hydrolysis temperature is 90 to 95 ° C. When the reaction solution is measured at 2 minutes by a Pinnacle viscometer with a capillary inner diameter of 0.6 mm, adjust When the pH reaches 5.5, the hydrolysis is terminated, and the hydrolyzed product is obtained, and the hydrolysis reaction time is 1.2h

[0038] c. Cool the hydrolyzate prepared in step b to 55-60°C, add 13.5 parts by weight of activated carbon, decolorize for 1 hour, and filter after decolorization;

[0039] d. Ultrafiltration and drying of the filtrate prepared in step c, to obtain final product.

[0040] The obtained sample had a molecular weight (MW) of 14,600 Da and a water content of 3.94%.

Embodiment 3

[0041] Embodiment 3 Preparation of icodextrin of the present invention

[0042] a. prepare the acid solution whose concentration of hydrochloric acid is 1.2%;

[0043] b. Take 1000 parts by weight of the acid solution, add 450 parts by weight of cornstarch under stirring, the hydrolysis temperature is 95°C, and after 1.0 hours of hydrolysis reaction, adjust the pH to 5.5 to obtain a hydrolyzate;

[0044] c. Cool the hydrolyzate prepared in step b to 55° C., add 13.5 parts by weight of activated carbon, decolorize for 1 hour, and filter after decolorization;

[0045] d. Ultrafiltration and drying of the filtrate prepared in step c, to obtain final product.

[0046] The obtained sample had a molecular weight (MW) of 13,800 Da and a water content of 3.86%.

[0047] The beneficial effects of the present invention are demonstrated through specific experiments below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com