A kind of preparation method of structure-stable lithium battery composite electrode powder material

A composite electrode and powder material technology, applied in battery electrodes, lithium batteries, structural parts, etc., can solve the problems of decreased safety and cycle stability, no chemical bonding, difficult structure control, etc., to avoid cycle stability Decrease, avoid growth and agglomeration, improve electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

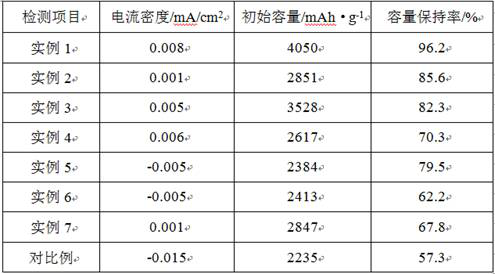

Examples

example 1

[0036] Pretreatment graphene oxide dispersion: by weight parts, successively take 5 parts of graphene oxide, 120 parts of water, 1.2 parts of polystyrene sodium sulfonate, pour into the mixer, and under the condition of ultrasonic frequency of 80kHz, After ultrasonic dispersion for 2 hours, the material in the mixer is transported to the spray dryer by a screw pump. When the feed rate is 60g / min, the inlet air temperature of the spray dryer is 100°C, and the outlet air temperature is 80°C. Under the condition of rotating speed of 12000r / min, spray granulation to obtain pretreated graphene oxide, and then mix the obtained pretreated graphene oxide and deionized water at a mass ratio of 1:10, and then ultrasonicate at an ultrasonic frequency of 65kHz Disperse for 45 minutes to obtain a pretreated graphene oxide dispersion;

[0037] Modified gelatin dispersion: mix gelatin with an isoelectric point of 6.0 and deionized water at a mass ratio of 1:10, pour it into a beaker, stir an...

example 2

[0043] Pretreatment graphene oxide dispersion: by weight parts, successively take 5 parts of graphene oxide, 120 parts of water, 1.2 parts of polystyrene sodium sulfonate, pour into the mixer, and under the condition of ultrasonic frequency of 80kHz, After ultrasonic dispersion for 2 hours, the material in the mixer is transported to the spray dryer by a screw pump. When the feed rate is 60g / min, the inlet air temperature of the spray dryer is 100°C, and the outlet air temperature is 80°C. Under the condition of rotating speed of 12000r / min, spray granulation to obtain pretreated graphene oxide, and then mix the obtained pretreated graphene oxide and deionized water at a mass ratio of 1:10, and then ultrasonicate at an ultrasonic frequency of 65kHz Disperse for 45 minutes to obtain a pretreated graphene oxide dispersion;

[0044] Modified gelatin dispersion: mix gelatin with an isoelectric point of 6.0 and deionized water at a mass ratio of 1:10, pour it into a beaker, stir an...

example 3

[0050] Pretreatment graphene oxide dispersion: by weight parts, successively take 5 parts of graphene oxide, 120 parts of water, 1.2 parts of polystyrene sodium sulfonate, pour into the mixer, and under the condition of ultrasonic frequency of 80kHz, After ultrasonic dispersion for 2 hours, the material in the mixer is transported to the spray dryer by a screw pump. When the feed rate is 60g / min, the inlet air temperature of the spray dryer is 100°C, and the outlet air temperature is 80°C. Under the condition of rotating speed of 12000r / min, spray granulation to obtain pretreated graphene oxide, and then mix the obtained pretreated graphene oxide and deionized water at a mass ratio of 1:10, and then ultrasonicate at an ultrasonic frequency of 65kHz Disperse for 45 minutes to obtain a pretreated graphene oxide dispersion;

[0051] Gelatin dispersion: mix gelatin with an isoelectric point of 6.0 and deionized water at a mass ratio of 1:10 and pour it into a beaker, stir and mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com