Method for preparing (Zn,Cd)S quantum dot

A technology of quantum dots and quantum dot solutions, applied in the field of semiconductor nanomaterial preparation, can solve the problems of complex preparation of inverse microemulsion systems or stencil solutions, poor operability and repeatability, and unfavorable industrial large-scale production, etc. To achieve the effect of easy large-scale industrial production, strong repeatability, and reduced preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

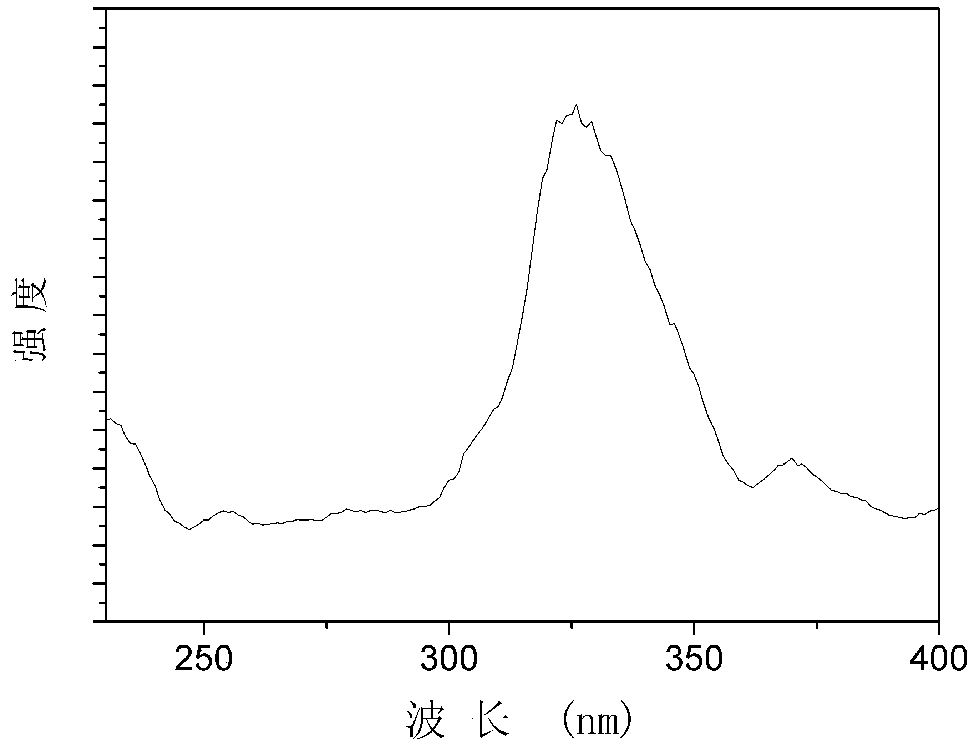

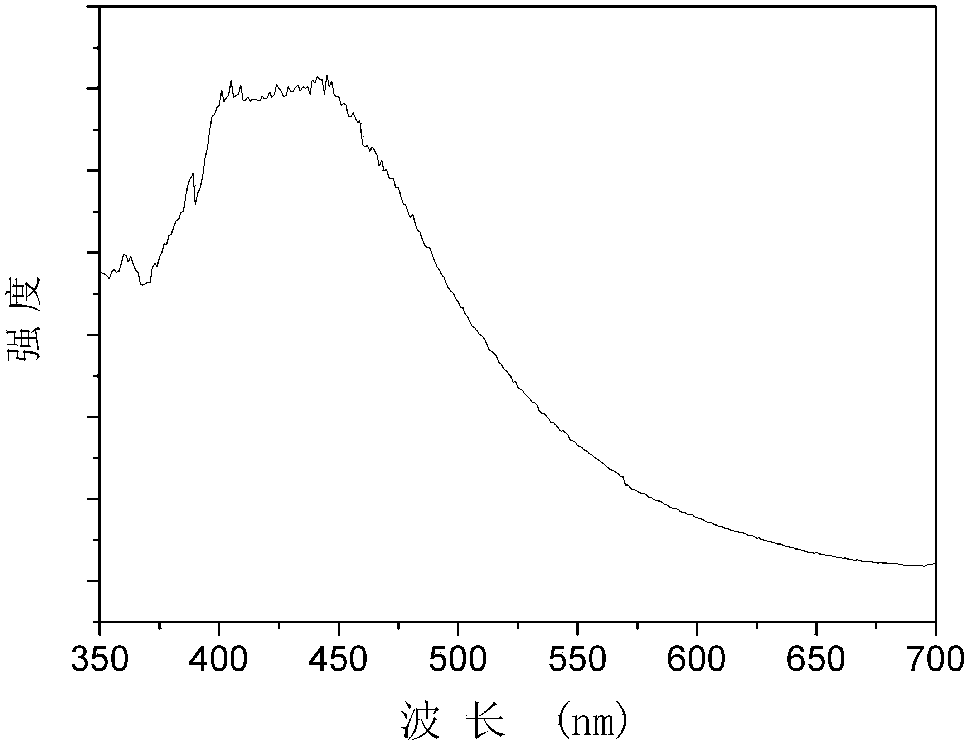

[0032] Take Zn(Ac) 2· 2H 2 O (Analytical Pure) and C 2 H 5 NS (Analytical Pure) is the starting material, dissolved in a 3:1 water / ethanol mixture at a molar ratio of 1:1, and adjust the pH to 5 with glacial acetic acid. Zn 2+ The initial concentration of 0.2mol / L. Transfer the above mixed solution to an autogenous pressure hydrothermal reactor (stainless steel shell, Teflon lining) with a filling degree of 75%, and heat it to 80°C for constant temperature reaction for 2 hours. After cooling, the ZnS quantum dot solution is obtained. The average particle size is 2.3 nm. Centrifugally separate the ZnS quantum dot solution, wash it with absolute ethanol, and put it in a vacuum drying oven. After drying at 80°C, ZnS quantum dot powder can be obtained. The excitation and emission spectra are shown in the attached file. figure 1 And figure 2 .

Embodiment 2

[0034] Take ZnCl 2 (Analytical pure) and C 2 H 5 NS (analytical grade) is the starting material, dissolved in a 3:1 water / ethanol mixture at a molar ratio of 1:1.5, and adjust the pH to 5 with glacial acetic acid. Zn 2+ The initial concentration of 0.2mol / L. The isothermal reaction time is 3 hours, and other conditions are the same as in Example 1. After cooling, ZnS quantum dots are obtained, and the average particle size of ZnS is 3.3 nm.

Embodiment 3

[0036] Take Zn(NO 3 ) 2· 6H 2 O (Analytical Pure) and C 2 H 5 NS (Analytical Pure) is the starting material, dissolved in a 3:1 water / ethanol mixture at a molar ratio of 1:2, and adjust the pH to 5 with glacial acetic acid. Zn 2+ The initial concentration of 0.2mol / L. The isothermal reaction time is 6 hours, and other conditions are the same as in Example 1. After cooling, ZnS quantum dots are obtained, and the average particle size of ZnS is 6.1nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com