A kind of hydrophobic association polymer and synthesis process

A hydrophobic association, polymer technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of inability to meet the requirements of tertiary oil recovery, poor temperature and salt resistance and shear resistance, and achieve the degree of hydrolysis. Controllable and adjustable, stable product quality, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

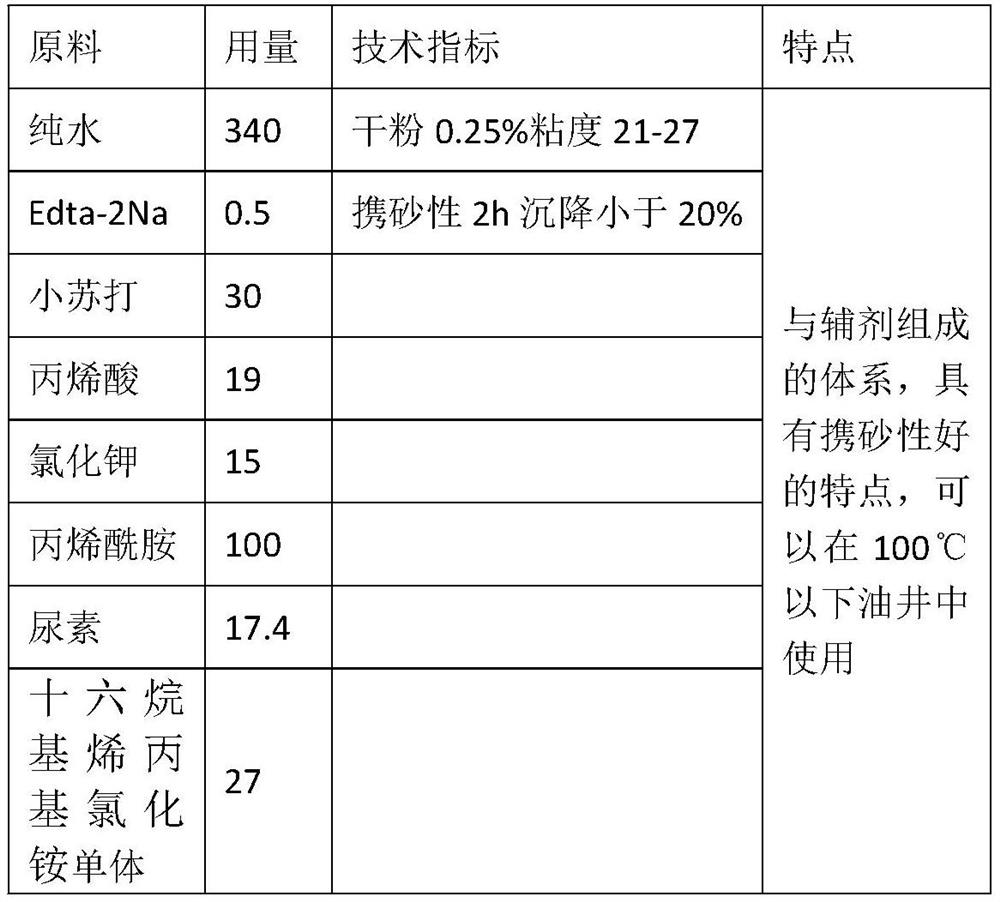

[0028] Hydrophobic association polymer ratio

[0029]

[0030] The synthesis process is as follows:

[0031] 1. Add pure water to the reactor.

[0032] 2. Turn on the stirring motor of the reactor and adjust the speed to 18r / min.

[0033] 3. Add EDTA. Stirring time 5 minutes.

[0034] 4. Slowly add baking soda and stir for 30 minutes until the material liquid becomes clear.

[0035] 5. Adjust the speed to 8r / min.

[0036] 6. Add acrylic acid, add slowly, and the feeding time is 30 minutes to prevent a large number of bubbles in the reaction kettle.

[0037] 7. After the bubbles in the reactor disappear, adjust the speed to 15r / min.

[0038] 8. Add KCl and stir for 10 minutes.

[0039] 9. Open the valve of the circulation system, open the filter, start the circulation pump, and circulate for 10 minutes after confirming that the circulation is smooth.

[0040] 10. Use a thermometer to measure the temperature of the feed liquid. If it exceeds 20°C, stop the cycle imme...

Embodiment 2

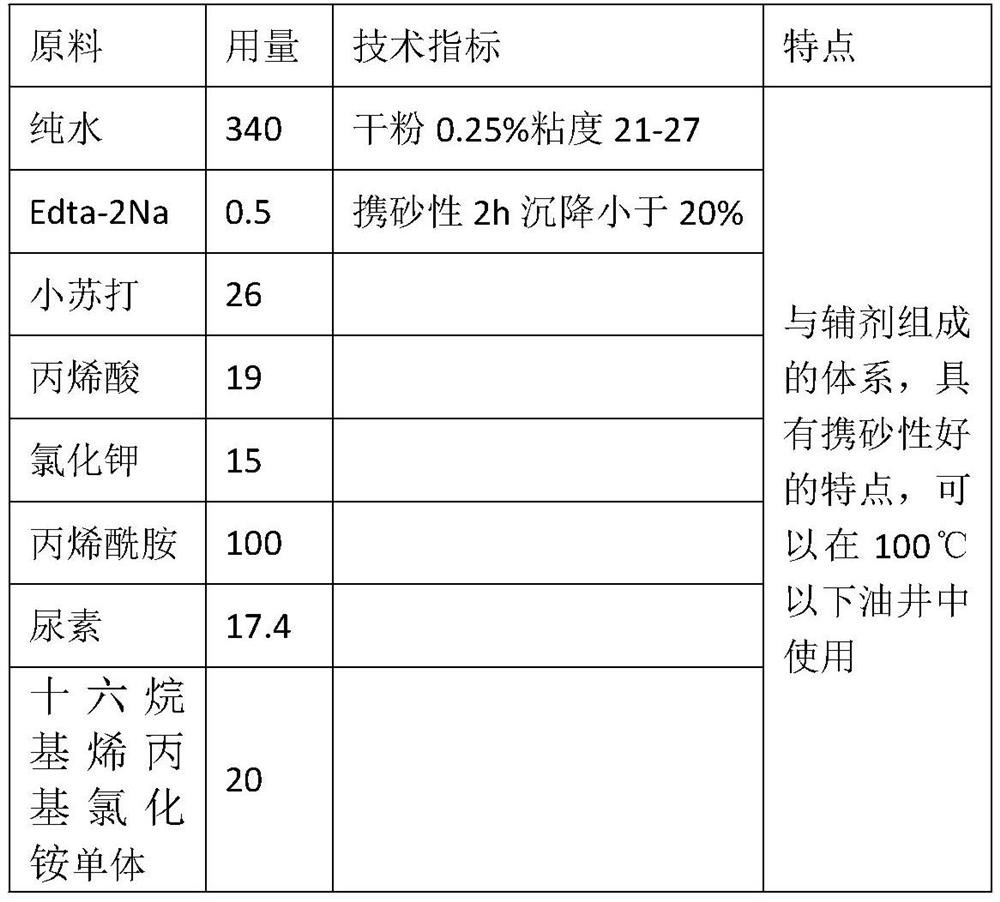

[0055] Hydrophobic association polymer ratio

[0056]

[0057] The synthesis process is as follows:

[0058] 1. Add pure water to the reactor.

[0059] 2. Turn on the stirring motor of the reactor and adjust the speed to 18r / min.

[0060] 3. Add EDTA. Stirring time 5 minutes.

[0061] 4. Slowly add baking soda and stir for 30 minutes until the material liquid becomes clear.

[0062] 5. Adjust the speed to 8r / min.

[0063] 6. Add acrylic acid, add slowly, and the feeding time is 30 minutes to prevent a large number of bubbles in the reaction kettle.

[0064] 7. After the bubbles in the reactor disappear, adjust the speed to 15r / min.

[0065] 8. Add KCl and stir for 10 minutes.

[0066] 9. Open the valve of the circulation system, open the filter, start the circulation pump, and circulate for 10 minutes after confirming that the circulation is smooth.

[0067] 10. Use a thermometer to measure the temperature of the feed liquid. If it exceeds 20°C, stop the cycle imme...

Embodiment 3

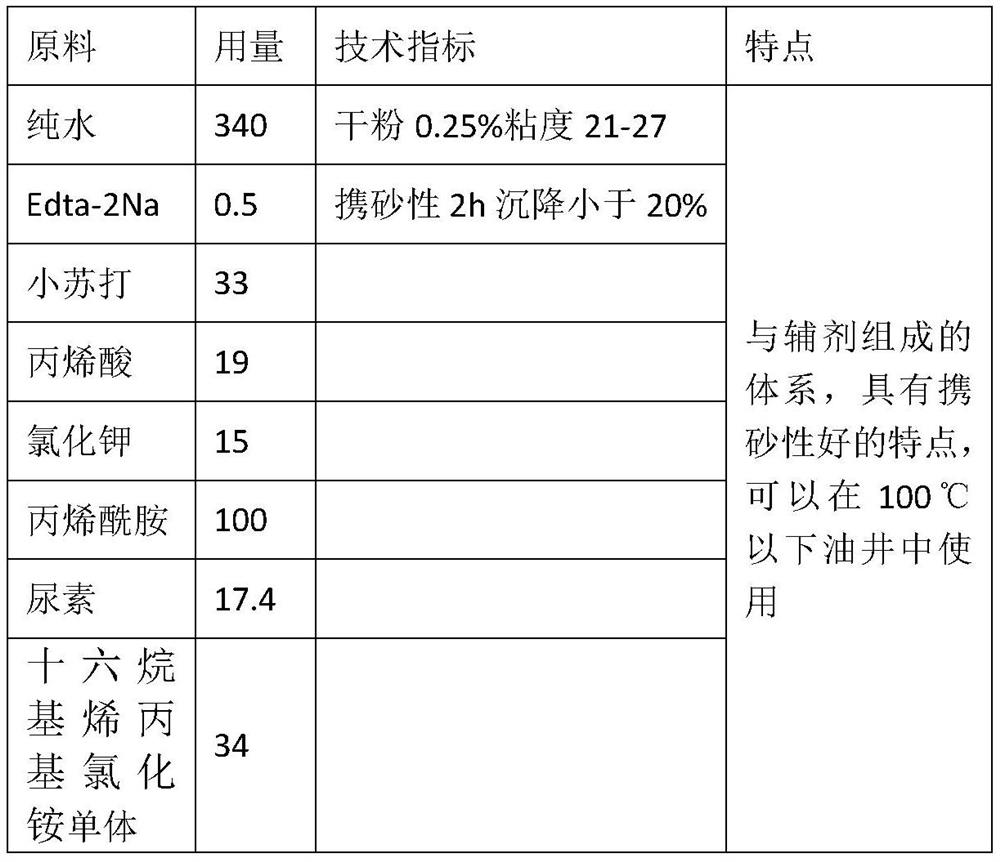

[0082] Hydrophobic association polymer ratio

[0083]

[0084] The synthesis process is as follows:

[0085] 1. Add pure water to the reactor.

[0086] 2. Turn on the stirring motor of the reactor and adjust the speed to 18r / min.

[0087] 3. Add EDTA. Stirring time 5 minutes.

[0088] 4. Slowly add baking soda and stir for 30 minutes until the material liquid becomes clear.

[0089] 5. Adjust the speed to 8r / min.

[0090] 6. Add acrylic acid, add slowly, and the feeding time is 30 minutes to prevent a large number of bubbles in the reaction kettle.

[0091] 7. After the bubbles in the reactor disappear, adjust the speed to 15r / min.

[0092] 8. Add KCl and stir for 10 minutes.

[0093] 9. Open the valve of the circulation system, open the filter, start the circulation pump, and circulate for 10 minutes after confirming that the circulation is smooth.

[0094] 10. Use a thermometer to measure the temperature of the feed liquid. If it exceeds 20°C, stop the cycle imme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com