Ship and hidden type anchor hole structure

A hidden, anchor hole technology, applied in the direction of ships, etc., can solve the problem of easy wear through of thickened plates, and achieve the effect of being beneficial to retraction, reducing frictional force and improving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

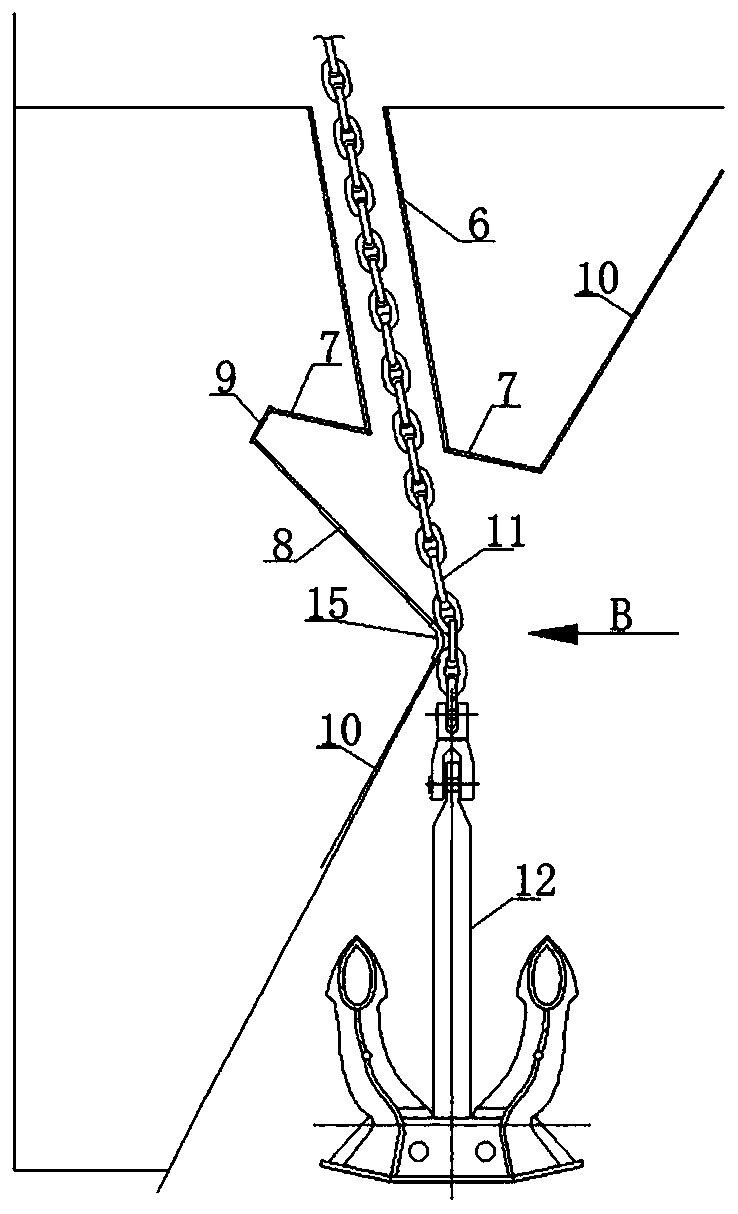

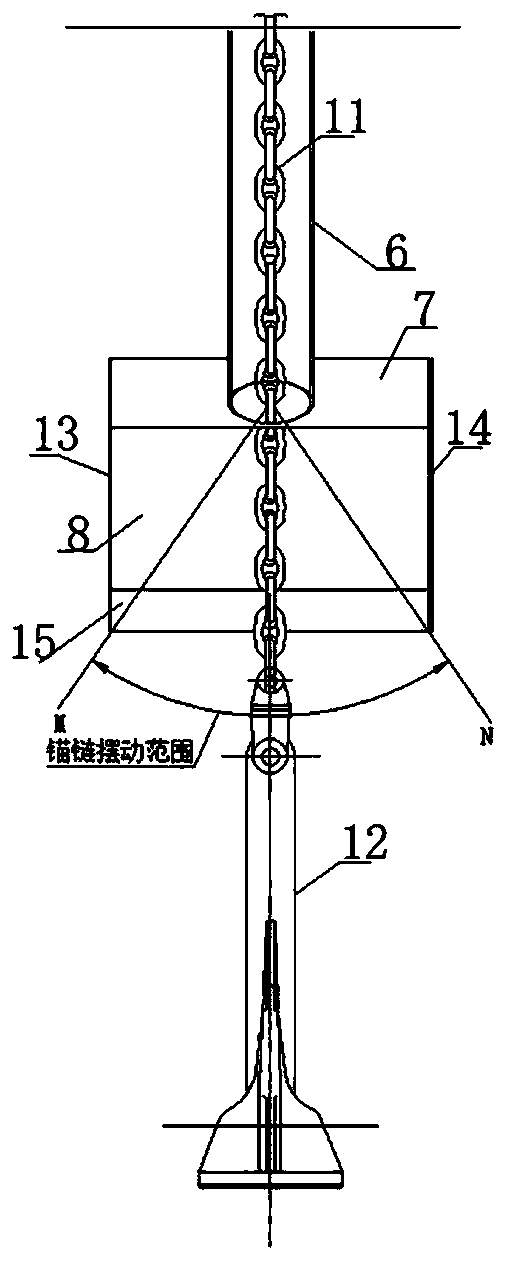

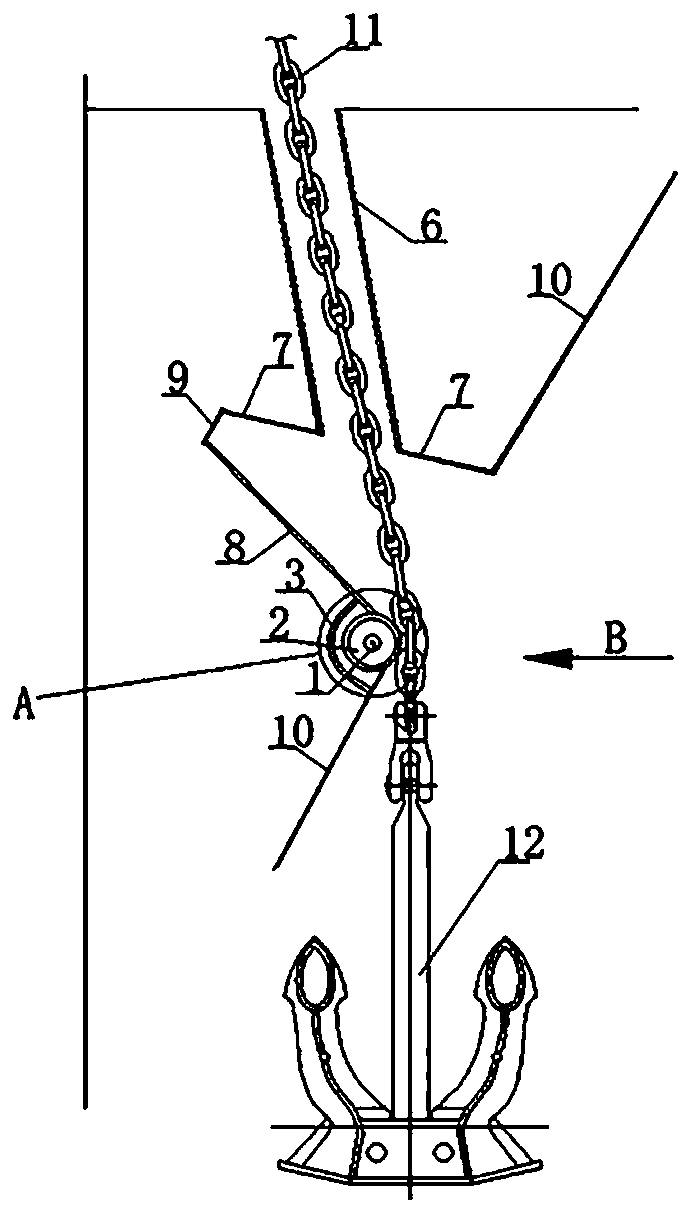

[0041] like Figure 3 to Figure 10 As shown, the ship includes a hull panel 10 and a hidden anchor cavity structure embedded in the hull panel 10. The hidden anchor cavity structure includes an anchor cavity top plate 7, an anchor cavity bottom plate 8, an anchor cavity back plate 9, and a left anchor cavity structure. Side plate 13 and right anchor hole side plate 14, left anchor hole side plate 13 and right anchor hole side plate 14 are all isosceles trapezoidal, left anchor hole side plate 13 and right anchor hole side plate 14 all constitute the present embodiment. Anchor hole side panels. The hidden anchor hole structure also includes an anchor chain pipe 6 connected to the anchor hole top plate 7, the anchor chain pipe 6 communicates with the inner space of the hidden anchor hole structure, and the anchor chain 11 of the ship is passed through the anchor chain pipe 6, And pass through the opening of the hidden anchor hole structure, and the lower end of the anchor chain...

Embodiment 2

[0046] Embodiment 2 of the ship of the present invention differs from Embodiment 1 in that the two ends of the rollers can be directly fixed on the left and right seals, so that when the anchor chain slides, the rollers do not rotate. Only the drum turns with the chain.

Embodiment 3

[0047] Embodiment 3 of the ship of the present invention differs from Embodiment 1 in that: the lower shutter is provided with a plurality of drain holes, so that the river water or sea water that enters from the gap between the drum and the upper shutter and the lower shutter It can be discharged from the weep hole, avoiding the problem of water blocking the rotation of the drum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com