Vacuum turbomolecular pump

A turbomolecular pump and vacuum technology, applied in pumps, pump control, axial flow pumps, etc., can solve problems such as increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

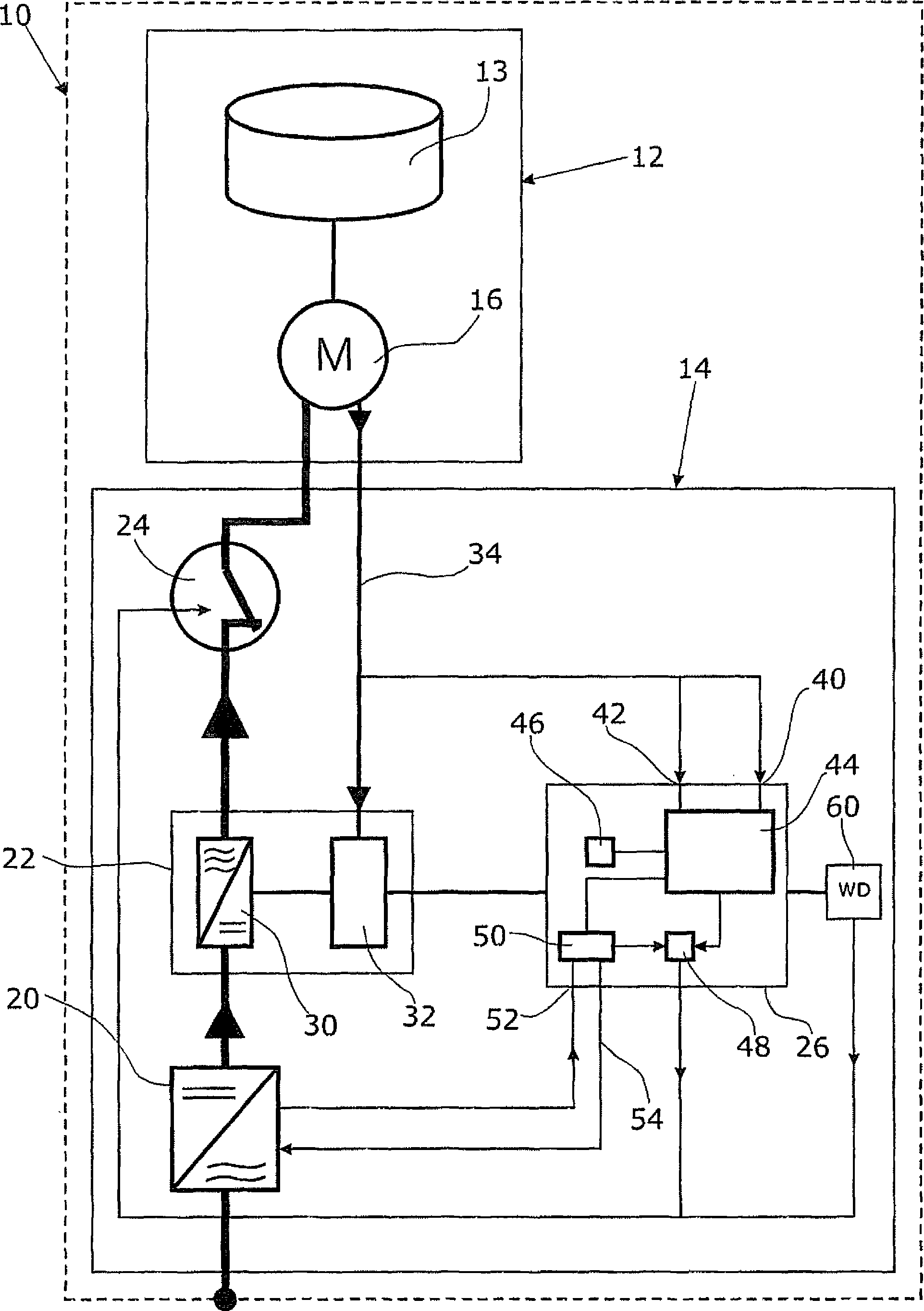

[0025] The drawing shows a high-speed rotating vacuum turbomolecular pump 10 which basically comprises a pump unit 12 and a control unit 14 . Turbomolecular pumps are used to generate high vacuum. This turbomolecular pump operates at a nominal rotational frequency f of 300 to 1600 Hz N run. The pump unit 12 has a pump rotor 13 and a drive motor 16 .

[0026] The control unit 14 includes the following main components: a power supply 20 , a motor control device 22 , a disconnection module 24 and a protection device 26 . The control unit 14 is used to control and monitor the drive motor 16 .

[0027] Due to the high rated rotational frequency of vacuum turbomolecular pumps, the rated rotational frequency f designed for the strength of the pump rotor should not be significantly exceeded N . Otherwise, the centrifugal force would be so high that the pump rotor 13 , or rather the rotor blades, would be damaged and could be thrown off dangerously. Since the casing of the pump u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com