A car flower machine for chain jewelry

A jewelry and chain-like technology, which is applied in the field of chain-shaped jewelry turning and embossing machines, can solve the problems of chain link inclination, chain link obstruction, unfavorable tool positioning and processing on the surface of the chain link, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

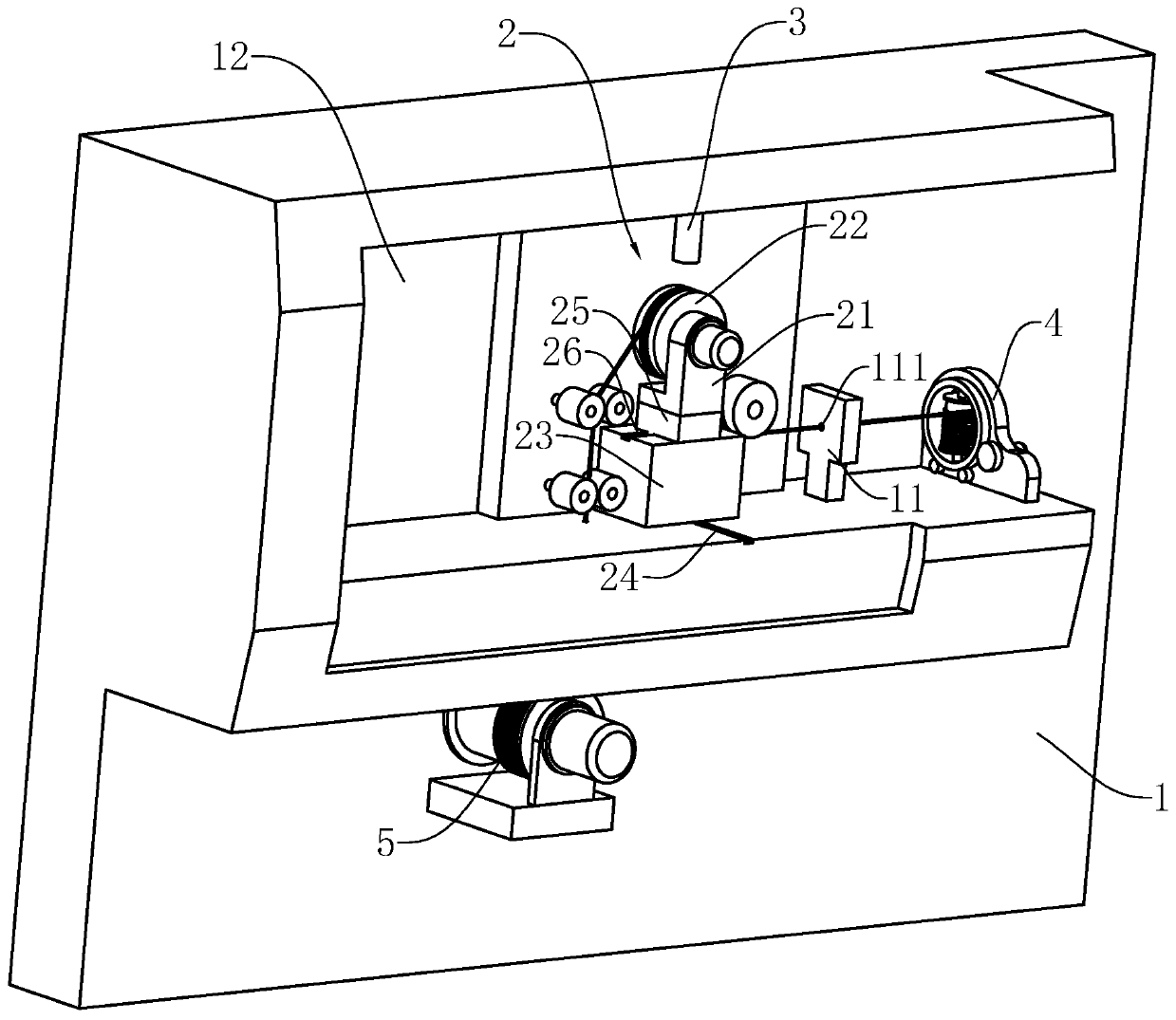

[0033] Such as figure 1 As shown, this embodiment introduces a car embossing machine for chain jewelry, including a frame 1, a support seat assembly 2 and a cutter 3, the frame 1 is placed on the ground, the frame 1 is placed on the ground, and the support seat assembly 2 is arranged above the frame 1, the cutter 3 is located above the support seat assembly 2, and the cutter 3 is relatively fixedly connected with the frame 1. The chain jewelry will first enter into the support seat assembly 2, and the support seat assembly 2 is used to support and limit the chain jewelry, and then the cutter 3 is used to perform car embossing operations on the jewelry.

[0034] Such as figure 1 As shown, a vertical side of the frame 1 is provided with an accommodating cavity 12 inwardly, the support seat assembly 2 is disposed above the lower side of the accommodating cavity 12 , and the cutter 3 is connected below the upper top surface of the accommodating cavity 12 . The tool 3 can be conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com