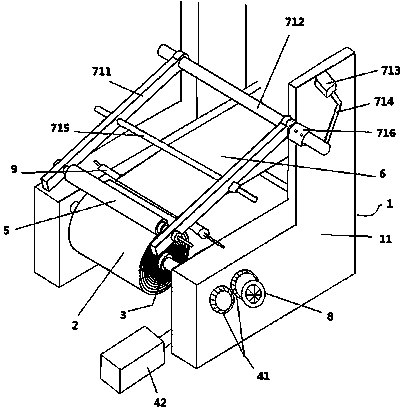

Thin film winding machine

A winding machine and film technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of insufficient adjustment accuracy of film tightness, uneven relaxation, uneven winding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0021] A specific embodiment of the present invention is as follows:

[0022] The servo motor 42 drives the sprocket set 41 by connecting the frequency converter, and the sprocket set 41 drives the rotating shaft 3 to rotate by meshing with the gear installed on the rotating shaft 3, and the rotating shaft 3 drives the reel 2 to rotate, and the reel 2 starts to roll the film 6 to work; In the process of winding the film 6, as the winding diameter of the film 6 gradually increases, the tension sensor that monitors the tension on the pinch roller 5 in real time will feed back the detected tension signal to the control box, and the control box will The processor of the computer sends an instruction through calculation, and the control cylinder 713 drives the swing arm 714 to fine-tune the pressure roller 5 to lift a certain distance, that is, to move a certain distance in the direction away from the reel 2, and it goes round and round, so that the pressure roller 5 is aligned with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com