Nodular cast iron pipe inner wall surrounding grinding device

A technology for ductile iron pipes and fixing devices, which is applied in the direction of grinding drive devices, grinding machines, grinding racks, etc., and can solve problems such as unevenness and deviation of the grinding position of the inner wall of the pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

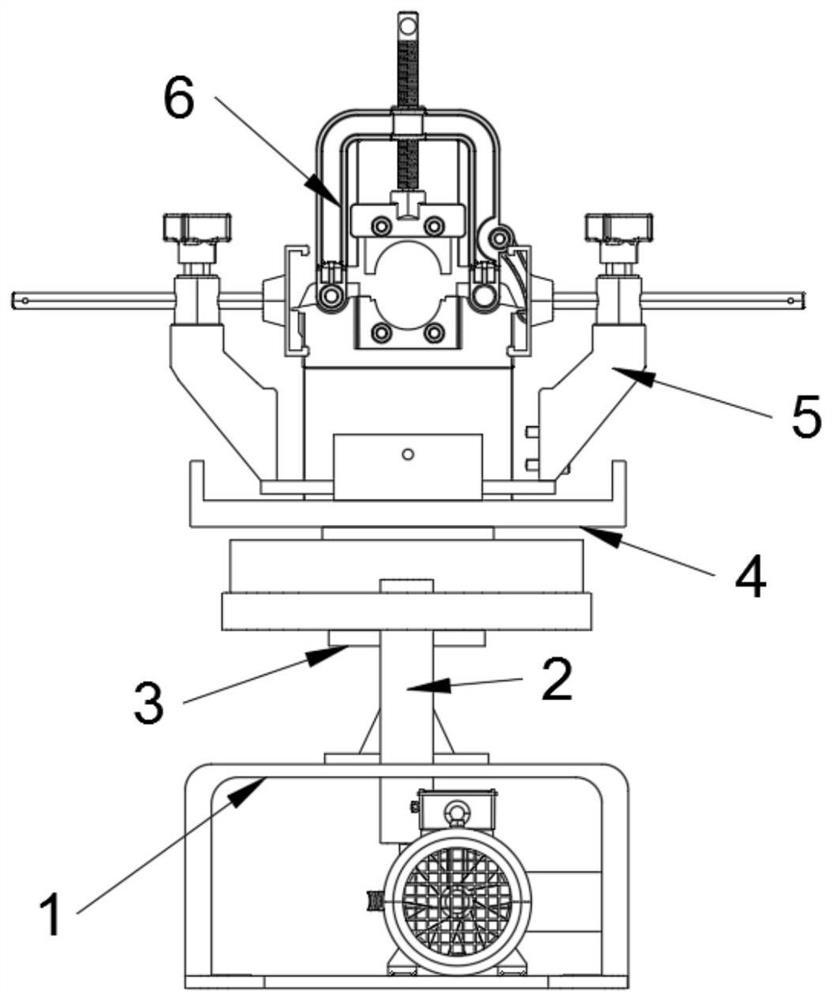

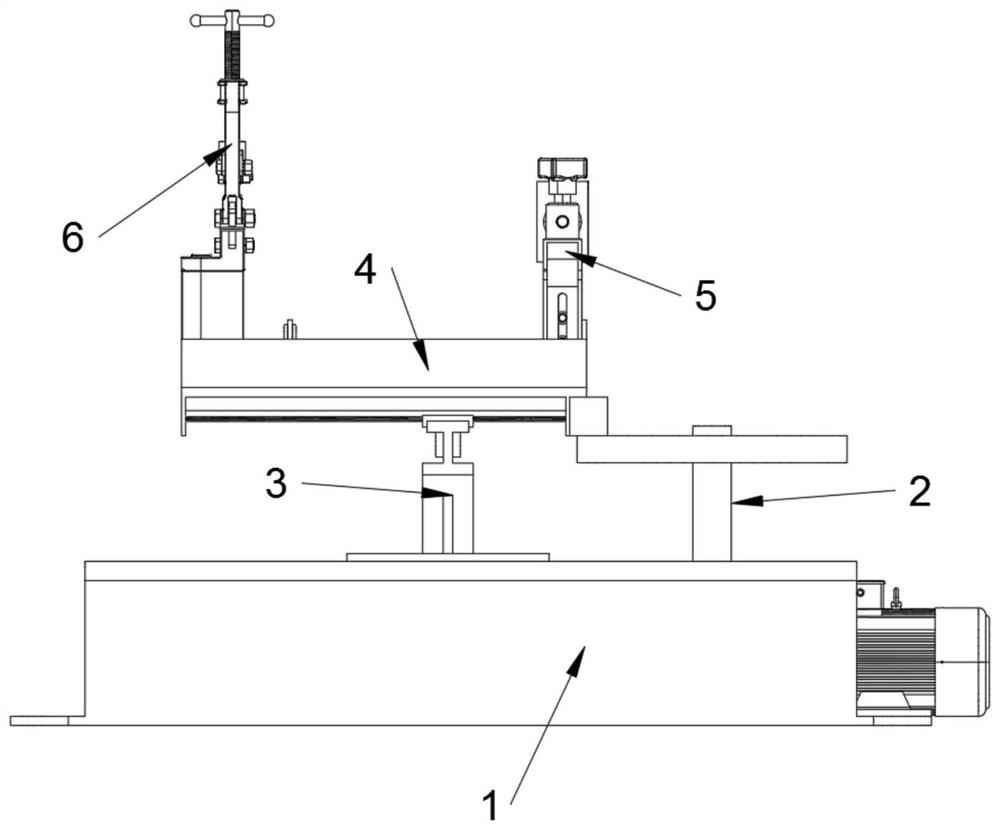

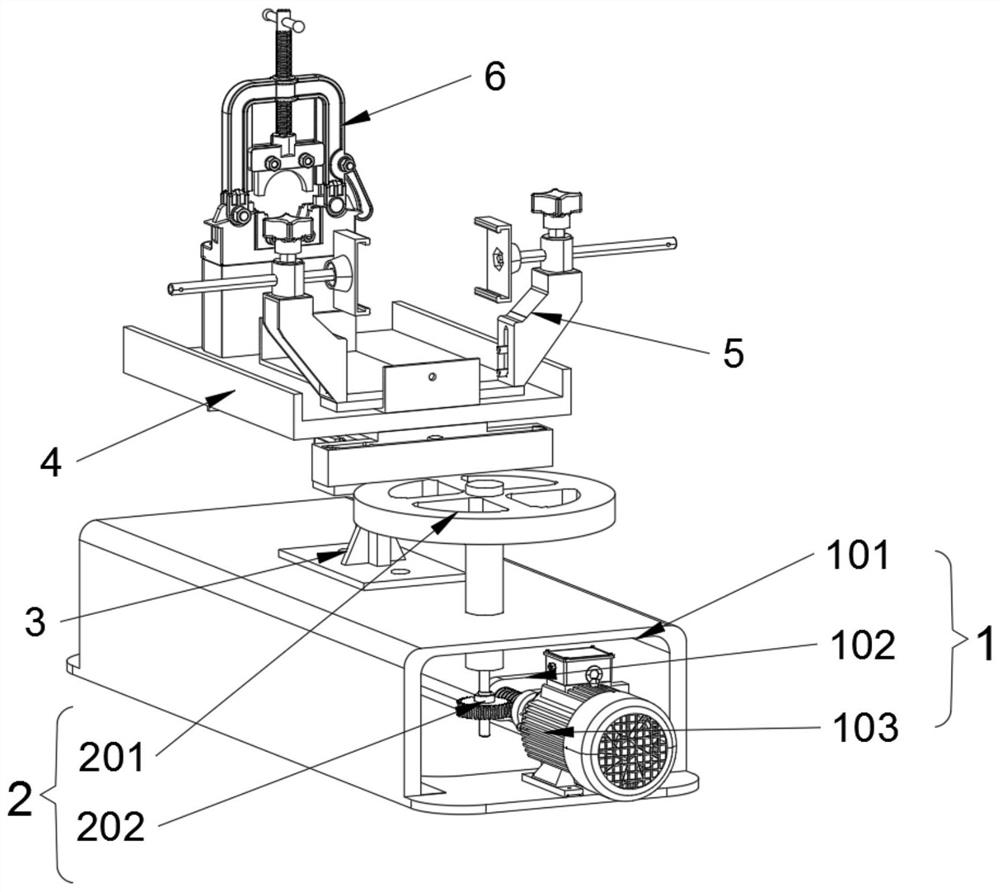

[0028] as attached figure 1 To attach Figure 6 Shown:

[0029] The invention provides a device for grinding the inner wall of a ductile iron pipe, which includes: a fixing device 1, a limit mechanism 3, a reciprocating mechanism 4, a clamping mechanism 5 and a fixing mechanism 6, and the middle position of the front end of the fixing device 1 is rotatably connected with a conductive Mechanism 2; the bottom of the limiting mechanism 3 is fixedly connected to the middle position of the top of the fixing device 1; the reciprocating mechanism 4 is connected to the top position of the limiting mechanism 3 through the cooperation of the transmission mechanism 2; the bottom of the clamping mechanism 5 is fixedly connected to the front end of the top of the reciprocating mechanism 4 Intermediate position; clamping mechanism 5 includes placing plate 501, clamping frame A502, clamping bar A503, clamping frame B504 and clamping bar B505, the position on the left side of the top surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com