General reducer with eccentric engagement pairs

A technology of meshing pairs and reducers, which is applied in hoisting devices, transmission devices, components with teeth, etc., can solve the problems of low transmission efficiency, power failure, and motion interference of reducers with small tooth differences, and achieve compact structure , simple and compact, the effect of improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

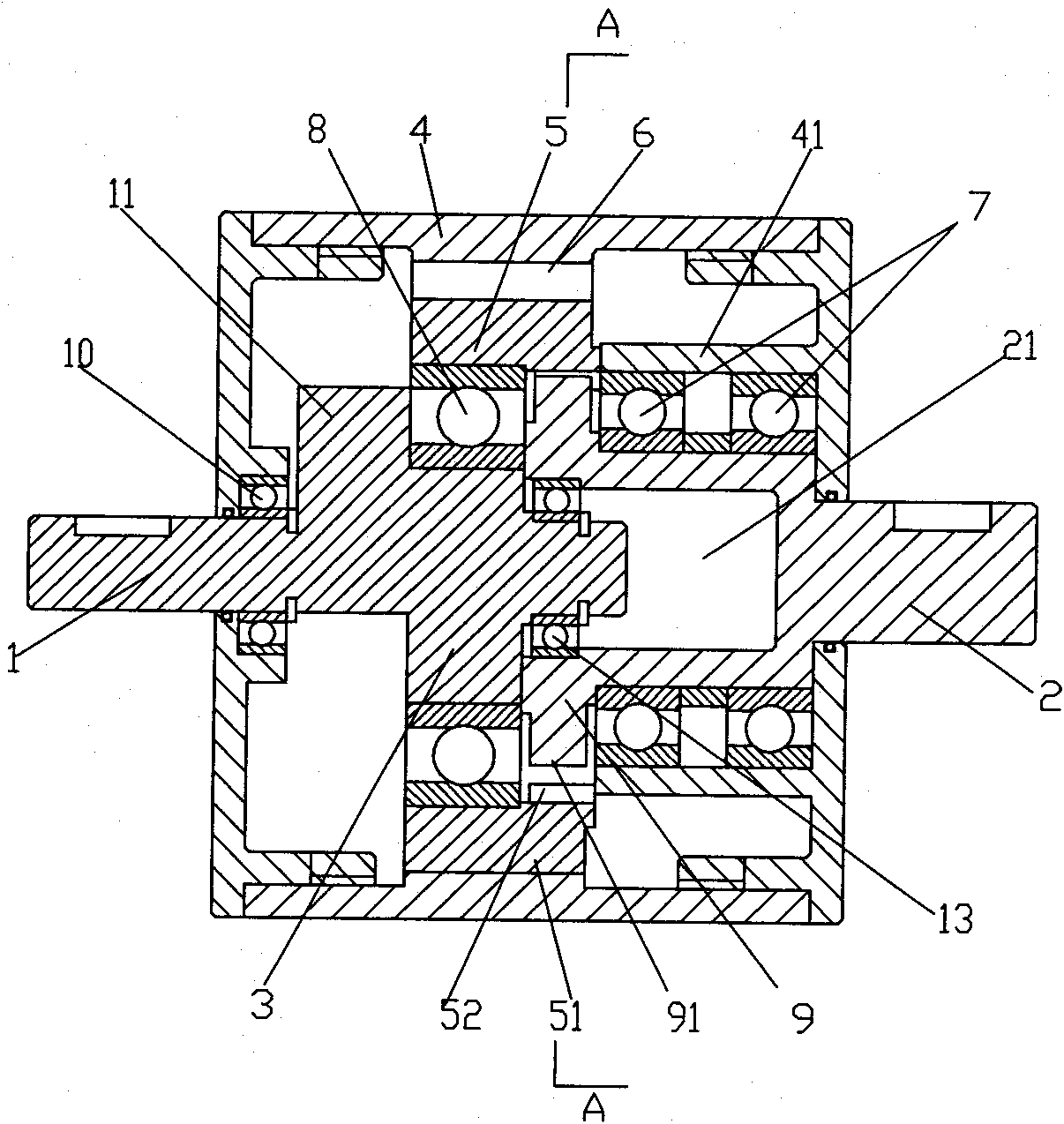

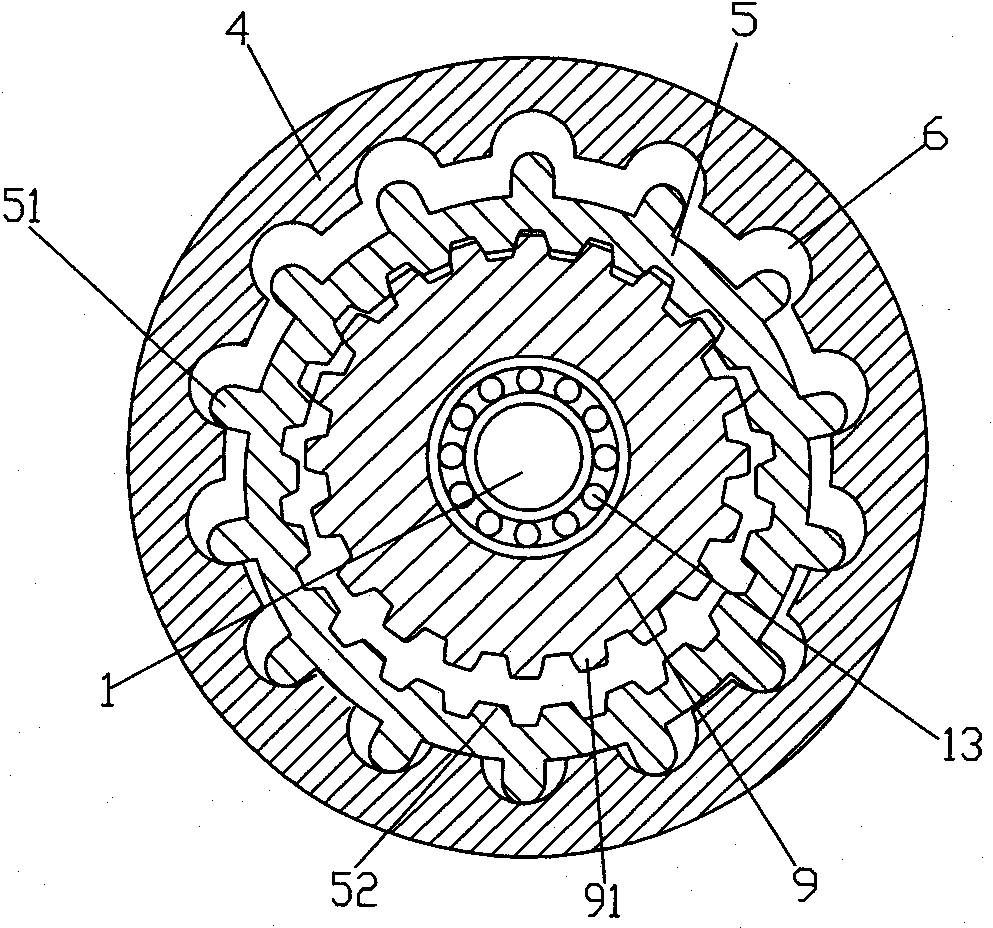

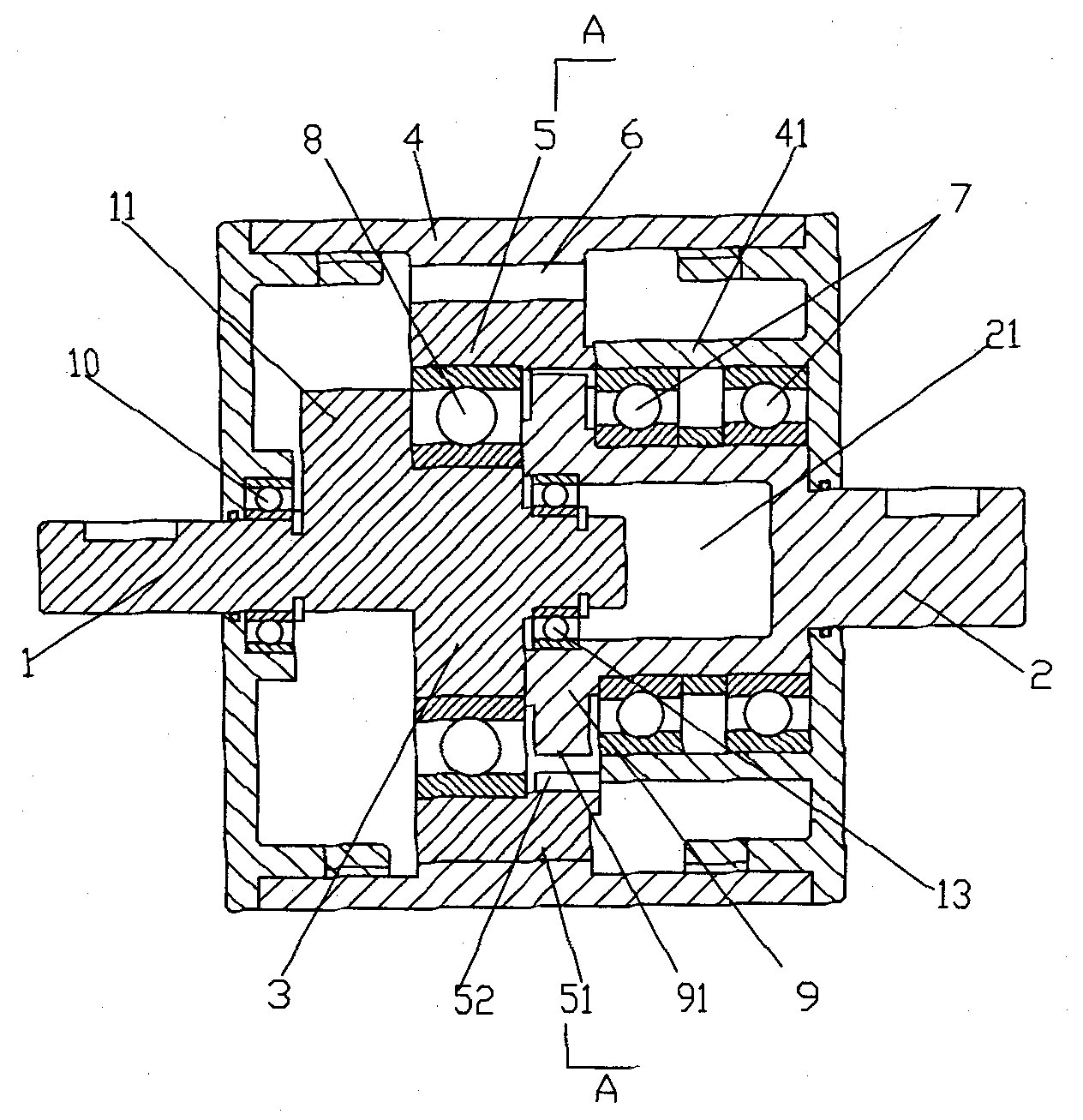

[0017] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 View along the direction of A-A, as shown in the figure: the universal reducer with eccentric meshing pair in this embodiment includes a housing 4, a power input shaft 1 and a power output shaft 2, and an eccentric sleeve is fixedly arranged on the power input shaft 1 in the circumferential direction 3. The outer circle of the eccentric sleeve 3 is rotated and fitted with a transmission tooth plate 5, and the outer circle of the transmission tooth plate 5 is provided with meshing teeth 51, which are fixed on the housing 4 and are concentric with the power input shaft 1 and are set to mesh with the meshing teeth 51 one by one. Engaging tooth groove 6, the groove width of the engaging tooth groove 6 in the circumferential direction is not narrower than the sum of the tooth width of the engaging tooth 51 in the circumferential direction and twice the eccentricity of the eccentri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com