2K-V speed reducer

A 2K-V, reducer technology, used in portable lifting devices, gear transmission devices, components with teeth, etc., can solve the problems of difficult and efficient processing, high manufacturing cost, poor processing technology, etc., and achieve good processing technology. , the effect of reducing manufacturing cost and manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

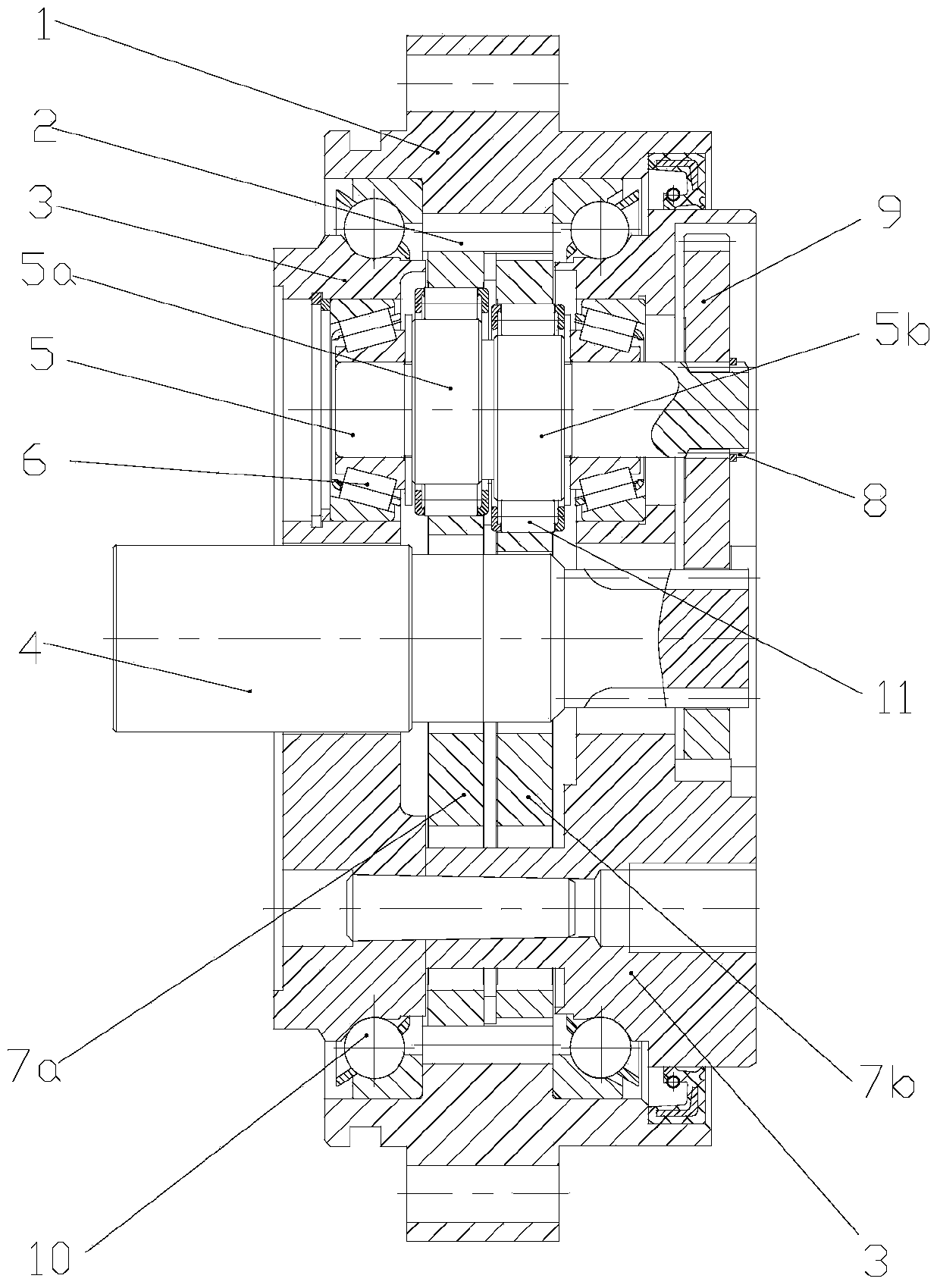

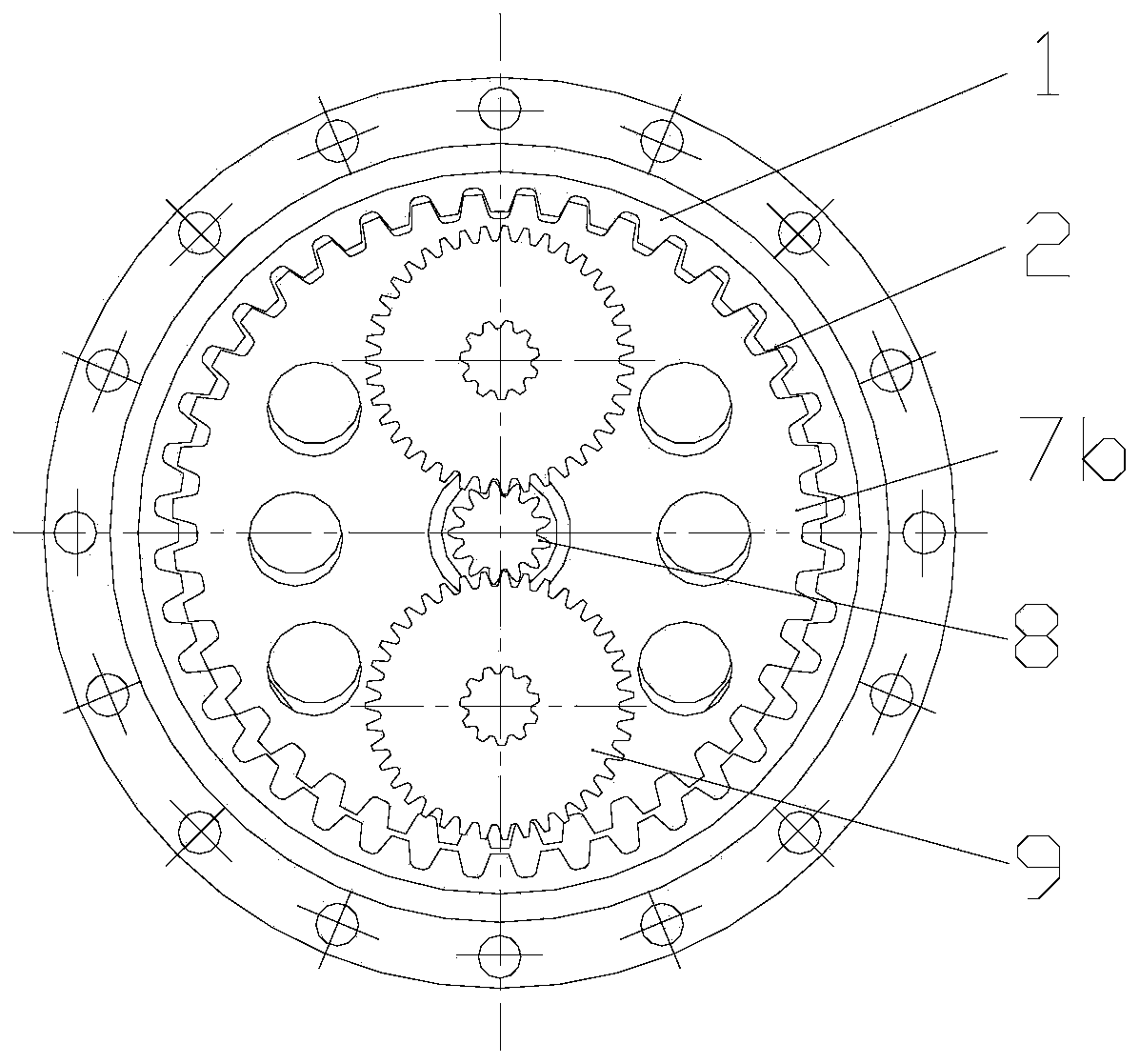

[0033] A reducer that can be used to connect to the joints of industrial robots, including a first-stage planetary gear mechanism and an involute planetary gear mechanism with few teeth difference. The first-stage planetary gear mechanism is composed of a central gear and a planetary gear, and the involute few teeth The differential planetary gear mechanism consists of an eccentric shaft, an external gear and an internal gear housing (including internal teeth). The power is input from the central gear, and transmitted to the outer gear through the eccentric shaft fixedly connected with the planetary gear. Driven by the eccentric shaft fixedly connected with the planetary gear, the outer gear swings in a plane under the force of the inner gear housing, which means it orbits the inner gear. The axis of the gear housing revolves, and then rotates around its own axis, and outputs the rotation motion of the external gear through the W mechanism.

[0034] The tooth profile of the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com