Dual-redundancy permanent magnet synchronous motor temperature rise calculation method based on equivalent thermal network model

A technology of permanent magnet synchronous motor and equivalent thermal network, which is applied in calculation, computer-aided design, electrical digital data processing, etc., can solve the problems of complex calculation and inability to reflect, and achieve simple calculation, high accuracy and less time-consuming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] Embodiment: The process of using the method of the present invention to obtain the temperature rise of the motor is described below by taking a 24-slot, 20-pole low-thermal coupling non-electromagnetic coupling double-redundant permanent magnet synchronous motor as an example.

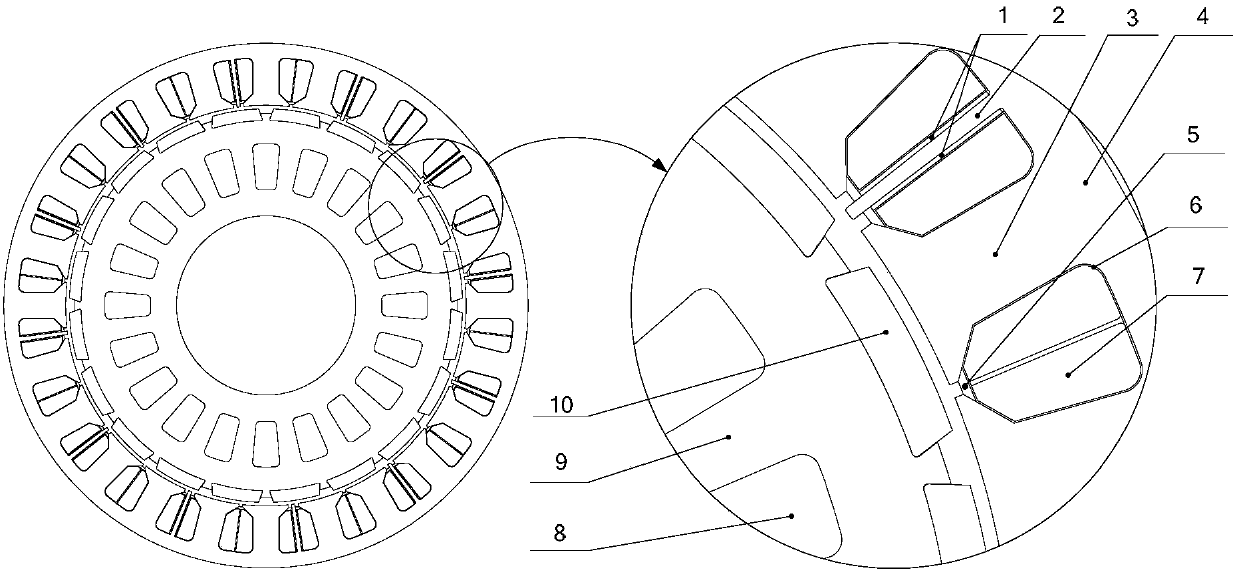

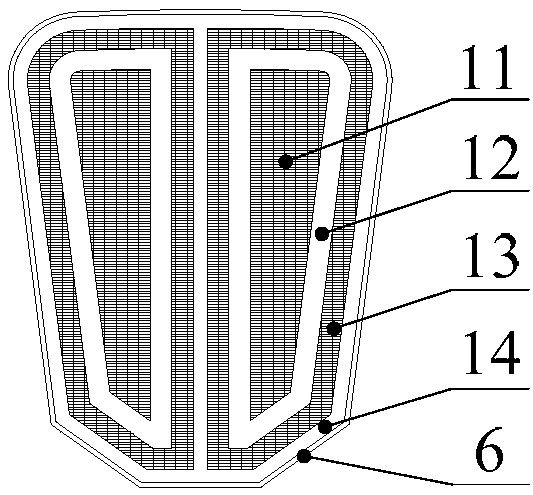

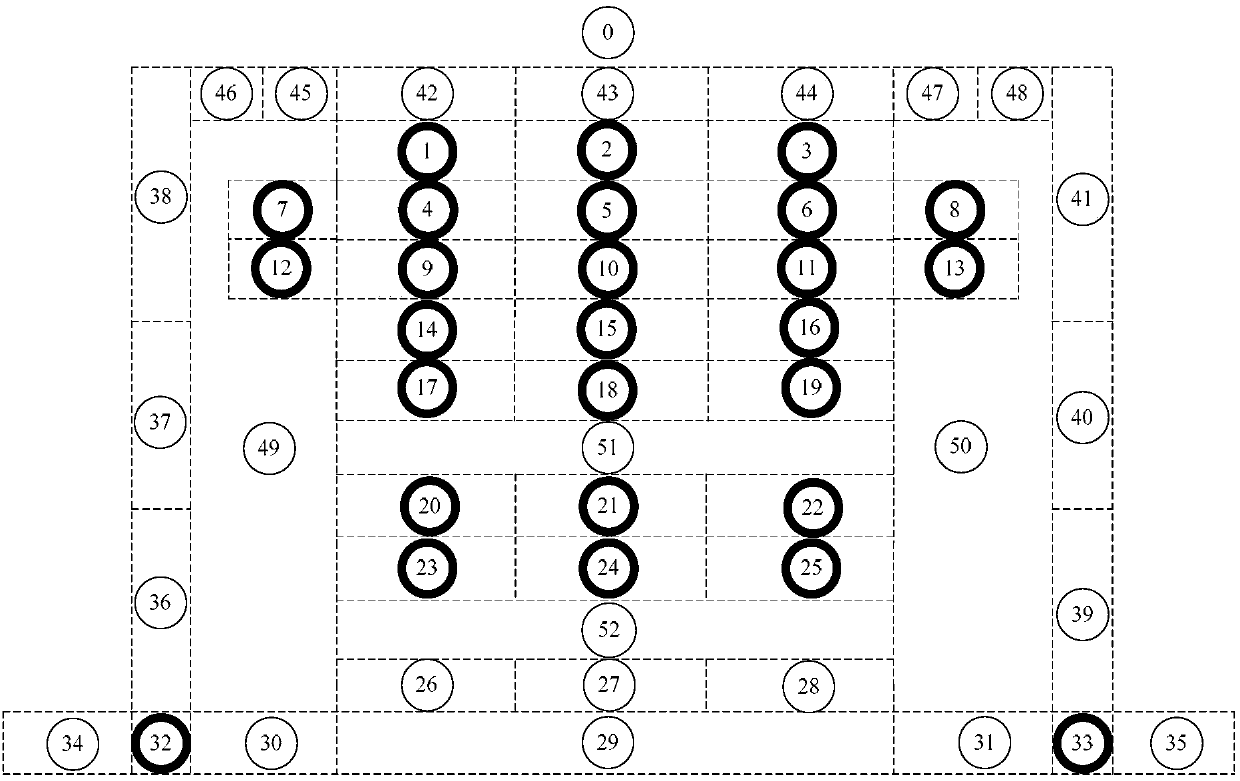

[0048] Such as figure 1 As shown, the 24-slot 20-pole low-thermal coupling non-electromagnetic coupling double-redundancy permanent magnet synchronous motor between each phase winding mainly includes stator yoke 4, large tooth 3, small tooth 2, heat shield 1, slot wedge 5, and slot insulation 6 , windings 7 in slots, permanent magnets 10, rotor core 9 and weight-reducing air holes 8, in addition to machine bases, end covers, shafts, bearings, air chambers inside the motor, air gaps between stators and rotors, and weight-reducing stomata, etc. The winding 7 in the slot is equivalent to figure 2 In the double-layer equivalent model shown, the equivalent division of the temperature rise node of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com