Gare changing thick involute planetary decelerating unit

A technology of planetary reducer and involute, which is applied in the direction of gear transmission, belt/chain/gear, transmission, etc., which can solve the problems of sensitive machining error of cycloidal pin wheel, complex process system, high product cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

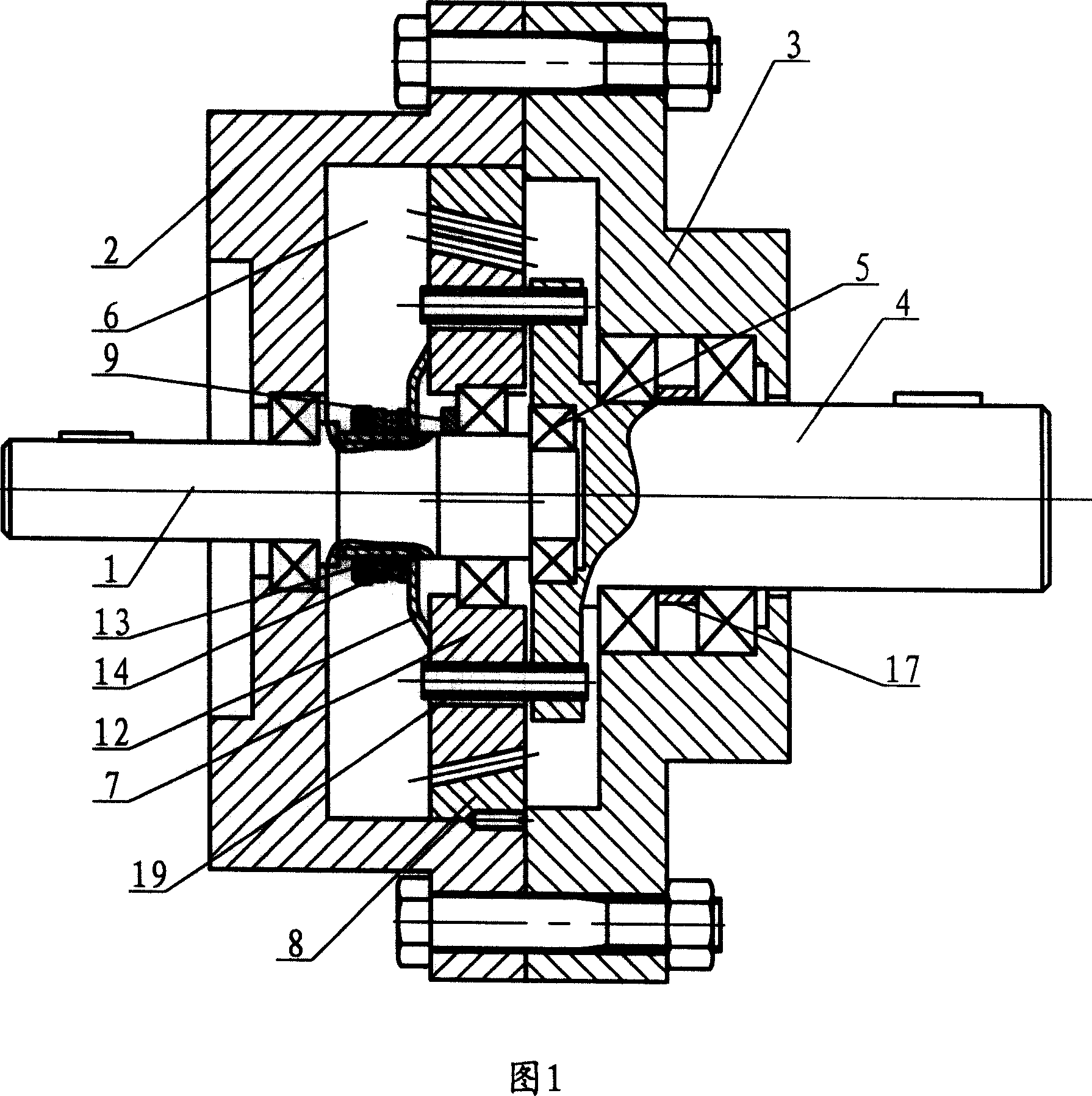

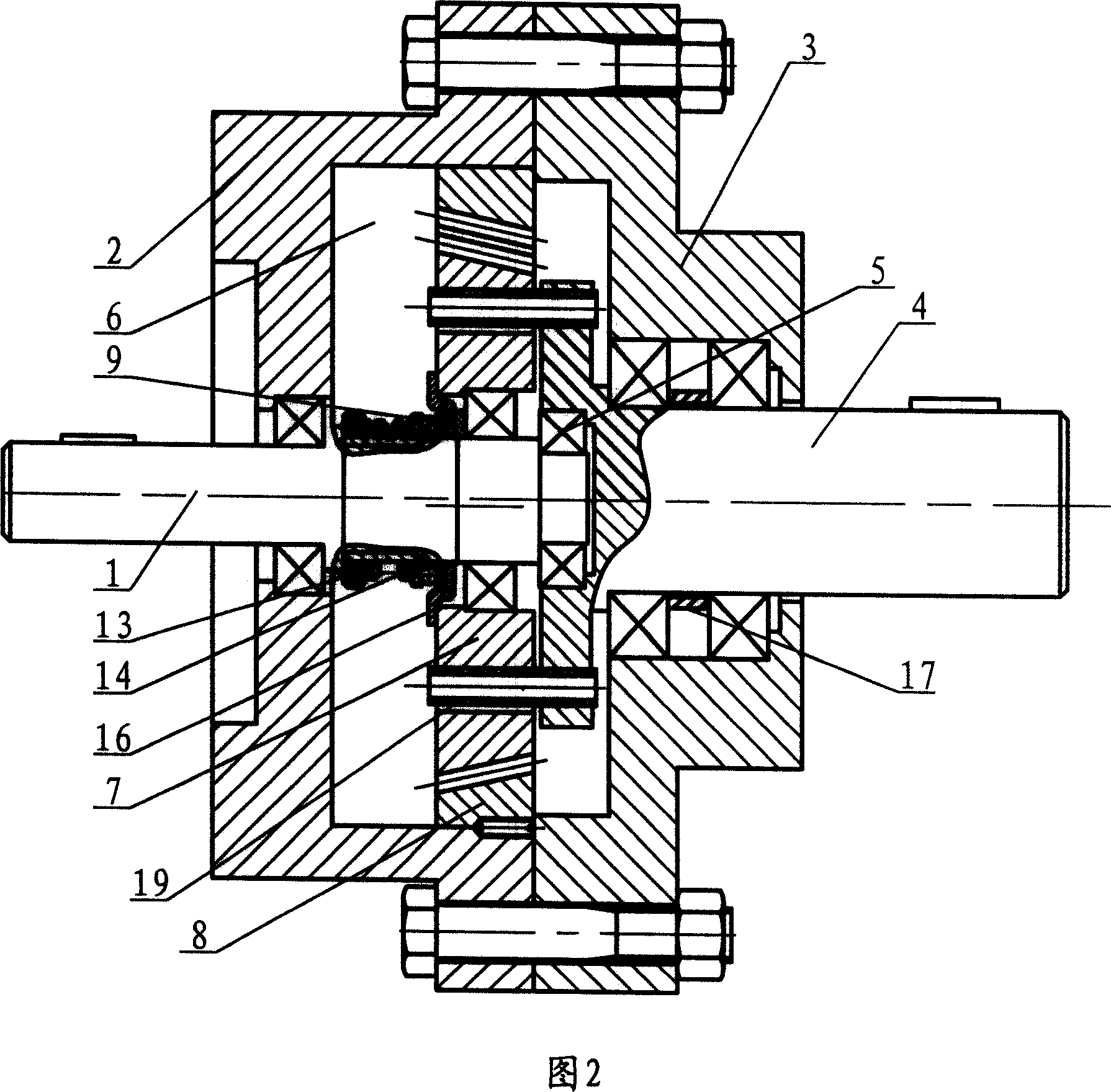

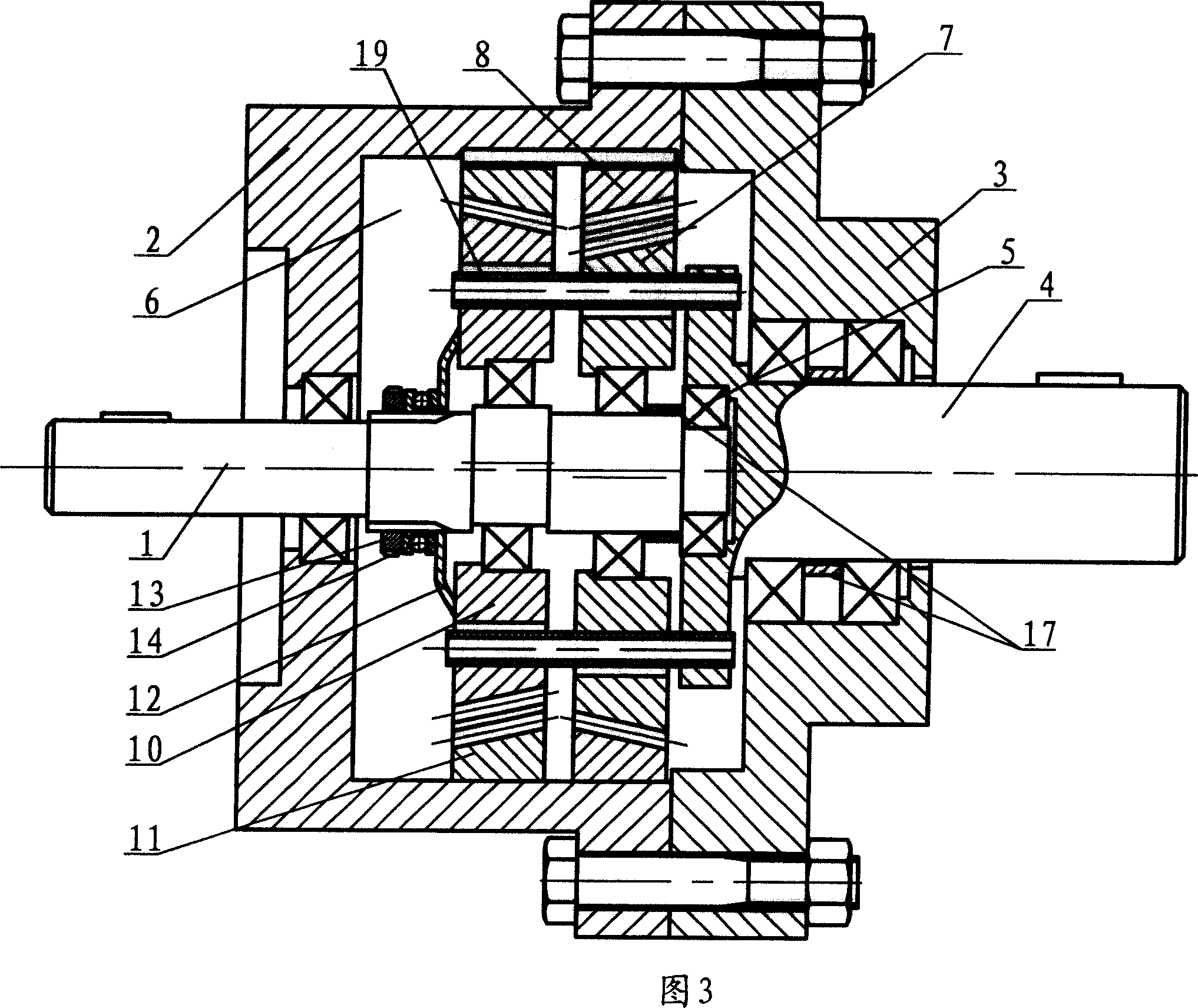

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0014] As shown in Figure 1, 2 or 3, the present invention comprises input eccentric shaft 1, left end cover 2, right end cover 3 and output shaft 4, wherein, output shaft 4 is installed on the input eccentric shaft by bearing 5, and left end cover passes bearing and The input eccentric shaft is connected, the right end cover is connected with the output shaft through bearings, the left end cover and the right end cover are fixedly connected to each other through bolts and nuts to form a working chamber 6, and a reduction mechanism connected with the input eccentric shaft and the output shaft is arranged in the working chamber It is characterized in that: the deceleration mechanism includes a variable tooth thickness involute planetary gear 7, a variable tooth thickness involute internal gear 8, and the variable tooth thickness involute planetary gear is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com