Virtual detection method for tooth error of involute bevel gear model

A tooth shape error and detection method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of avoiding inaccurate analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] The virtual detection method of the tooth shape error of the involute helical gear model of the present invention:

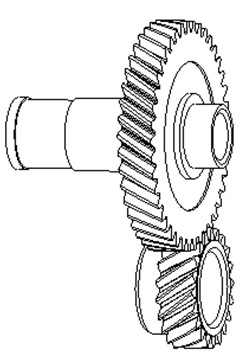

[0023] (1) if figure 1 As shown, transfer the assembled gear model into Pro / E software, in which, the modulus and pressure angle of the large and small wheels of the model are equal, and the helix angles on the pitch circles of the two wheels must be equal in size and opposite in direction of rotation;

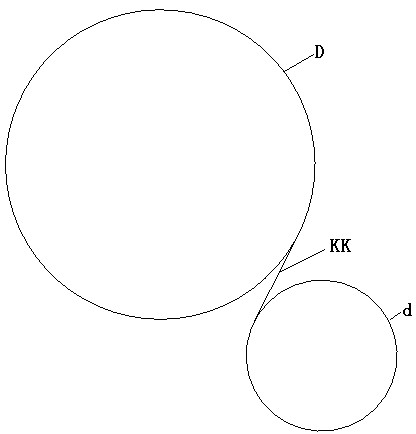

[0024] (2) if figure 2 As shown, when the tooth profile of the helical cylindrical gear meshes at any position, the contact line is a straight line parallel to the inner common tangent KK, and the contact line is always on the inner common tangent plane of the large gear base circle D and the pinion base circle d superior.

[0025] Firstly, adjust the angle of view of the model, and use the software's "sketch" and "l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com