Closed cycloid precision gear reducer

A precision reducer, closed-type technology, applied in hoisting devices, transmission devices, components with teeth, etc., can solve the problem that the machining accuracy cannot fully guarantee the consistency between the inner diameter of the pin hole and the outer diameter of the pin tooth pin, and the hysteresis is not easy Control, transmission efficiency reduction and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

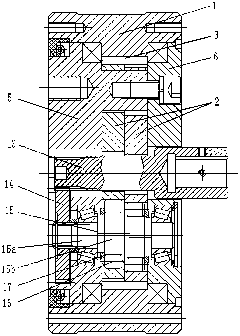

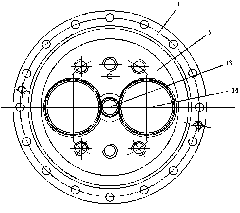

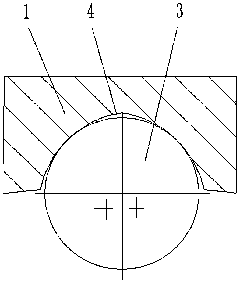

[0083] figure 1 It is a structural schematic diagram of the present invention; figure 2 for figure 1 left view of image 3 It is a schematic diagram of the structure of the double-arc containment tank; Figure 4 It is a schematic diagram of the structure of the parabolic containment tank; Figure 5 It is a comparison diagram of the cycloidal tooth profile of the standard tooth profile of the cycloidal wheel and the given meshing clearance; Image 6 It is an enlarged view of the axial and radial two-way support and rotation connection structure; Figure 7 An enlarged view of the integrated double eccentric bearing; Figure 8 An assembly diagram of the application of radial bearing rollers and axial bearing roller combinations for the present invention; Figure 9 An assembly drawing of the cross roller bearing applied to the present invention; Figure 10 It is the assembly diagram of angular contact bearing and tapered roller bearing applied in the present invention; as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com