Single-stage rigid tooth surface cycloid steel ball planetary gear reducer

A planetary reducer, cycloid steel ball technology, applied in mechanical equipment, gear transmission, components with teeth, etc., can solve the problems of high manufacturing and assembly precision requirements, increased manufacturing process difficulty, insufficient transmission rigidity, etc. , to achieve the effect of improving transmission efficiency, reducing unbalanced inertial force and high transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

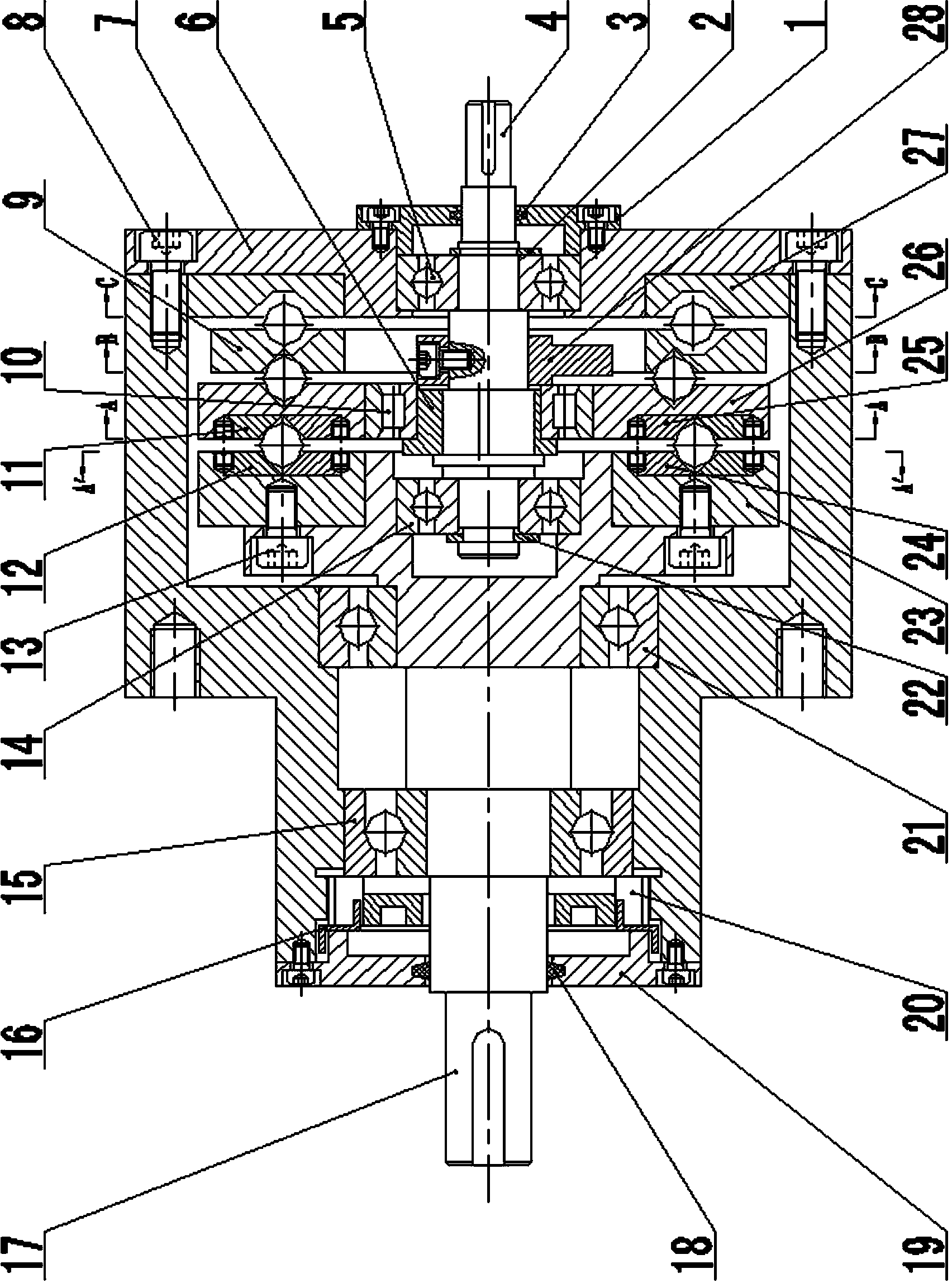

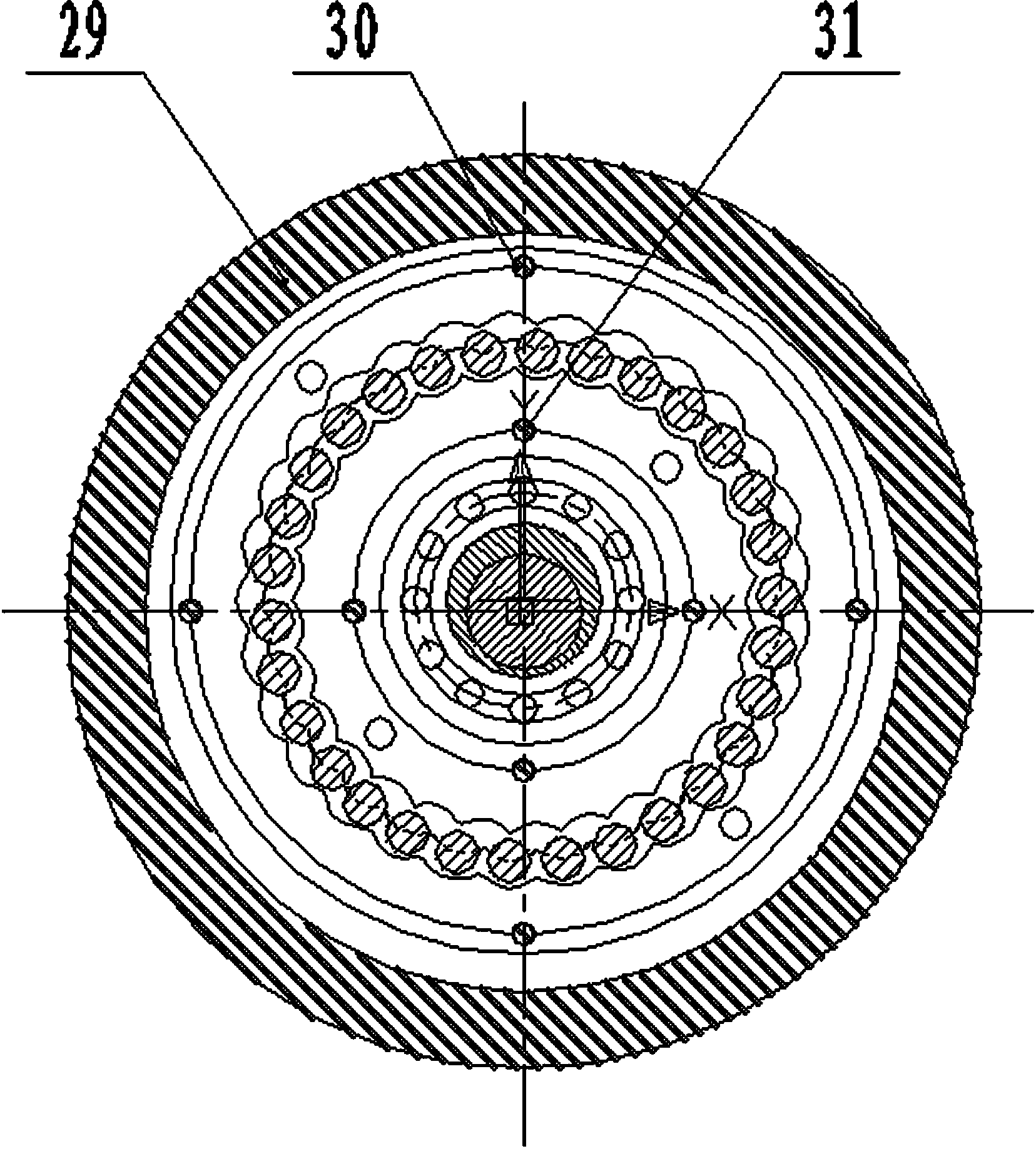

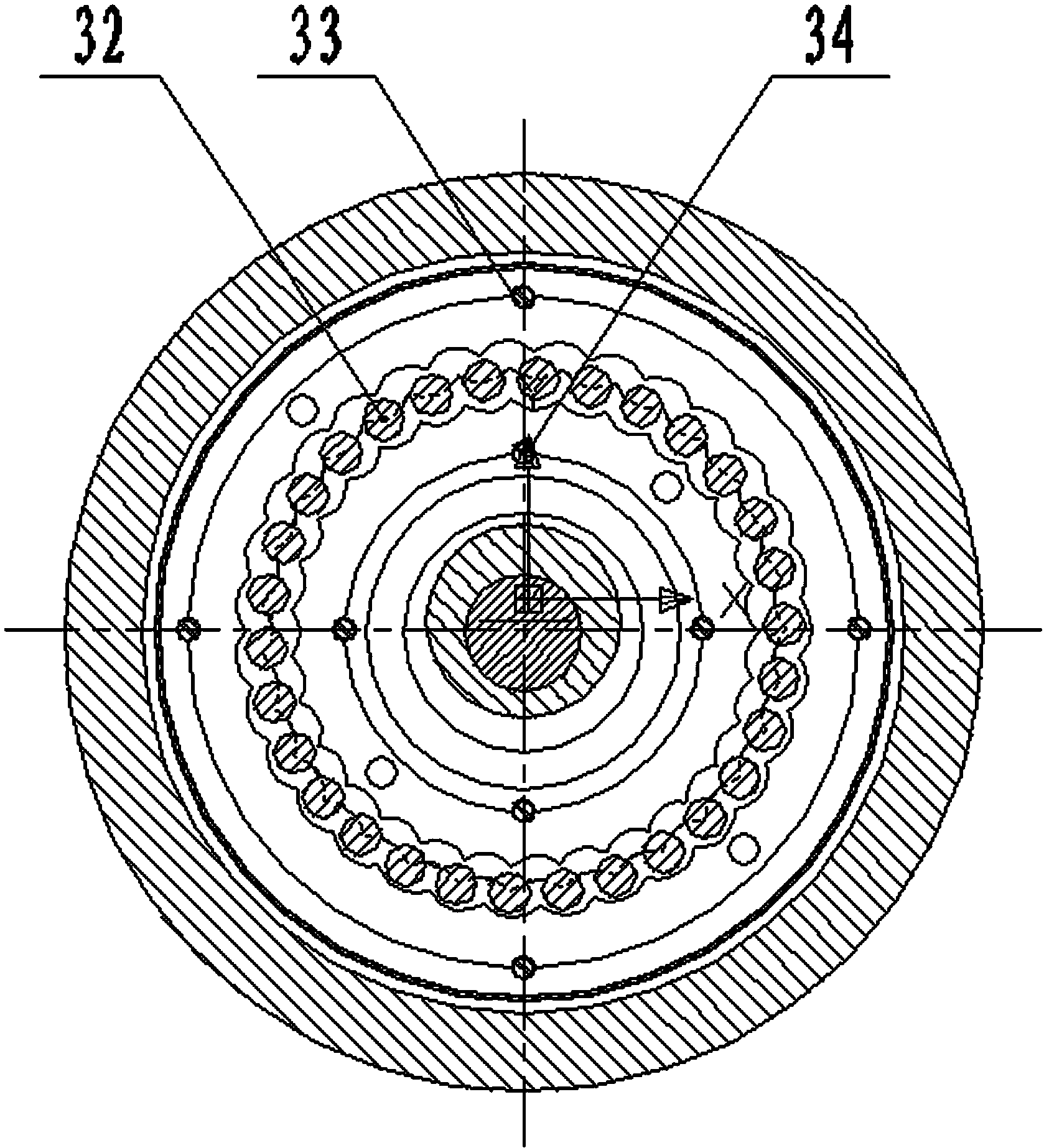

[0021] The accompanying drawings non-restrictively disclose the specific structure of an embodiment of the present invention. The present invention will be further described below in conjunction with the accompanying drawings.

[0022] Figure 1~5 As shown, the single-stage hard-tooth surface cycloid steel ball planetary reducer includes the right bearing end cover 1, the elastic retaining ring for the shaft 2, the felt ring oil seal 3, the input shaft 4, the input shaft right supporting bearing 5, the eccentric sleeve 6, the end Cover 7, screw set 8, swash plate 9, swing arm bearing 10, outer cycloid plate 11, hypocycloid outer plate 12, screw set 13, input shaft left support bearing 14 output shaft left support bearing 15, stop washer 16. Output shaft 17, felt ring oil seal 18, left bearing end cover 19, pre-tightening nut 20, output shaft right support bearing 21, shaft circlip 22, center disc 23, inner cycloid disc 24, outer cycloid Inner disc 25, planetary disc 26, end cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com