Preparation method of new combined tubular long-axis two-way elastic diaphragm coupling

An elastic diaphragm and combined technology, which is applied in the field of machine tool parts, can solve the problems of coaxiality and linearity, difficult to meet the transmission vibration of the coupling, low precision of the dynamic balance of the coupling, etc., and achieve high manufacturing accuracy , compact structure, good torsional rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

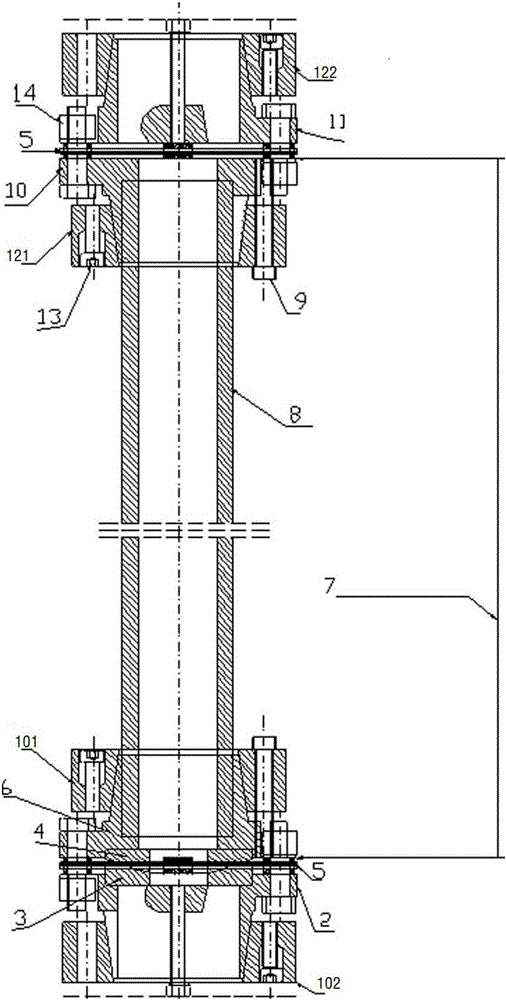

[0019] according to figure 1 As shown, a new combined tubular long-axis two-way elastic diaphragm coupling includes: the first assembly, the second assembly, the tubular middle long shaft 8, and the two ends of the tubular middle long shaft 8 in the split-type combined middle section 7 Respectively connect the first component and the second component;

[0020] The split-type combined intermediate section 7 includes: left outer cone-claw flange section 6, left outer cone-claw flange section 6 threadedly connected to the first left inner cone pressure sleeve 101; right outer cone-claw flange section 10. The right outer cone claw flange section 10 is threadedly connected to the first right inner cone pressure sleeve 121, and the first right inner cone pressure sleeve 121 is provided with a symmetrical dynamic balance adjustment position 13;

[0021] The first assembly includes: the riveted combined elastic diaphragm body 5 clamped by the lower support block 3 and the upper suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com