Low-heat coupling and non electromagnetic coupling dual-redundancy permanent-magnet synchronous motor between phase windings

An electromagnetic coupling and permanent magnet synchronization technology, which is applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit stationary parts, etc., can solve the problem of large volume and weight and increase system parameters Changes and other issues, to achieve the effects of low thermal influence, improved reliability, and low thermal coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

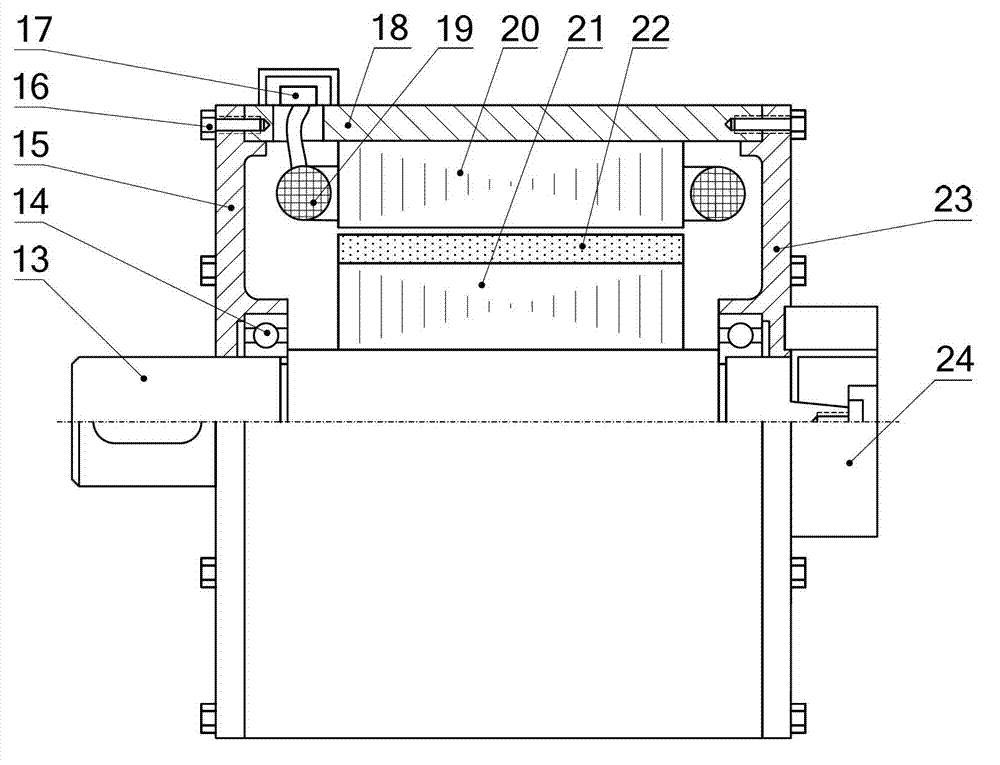

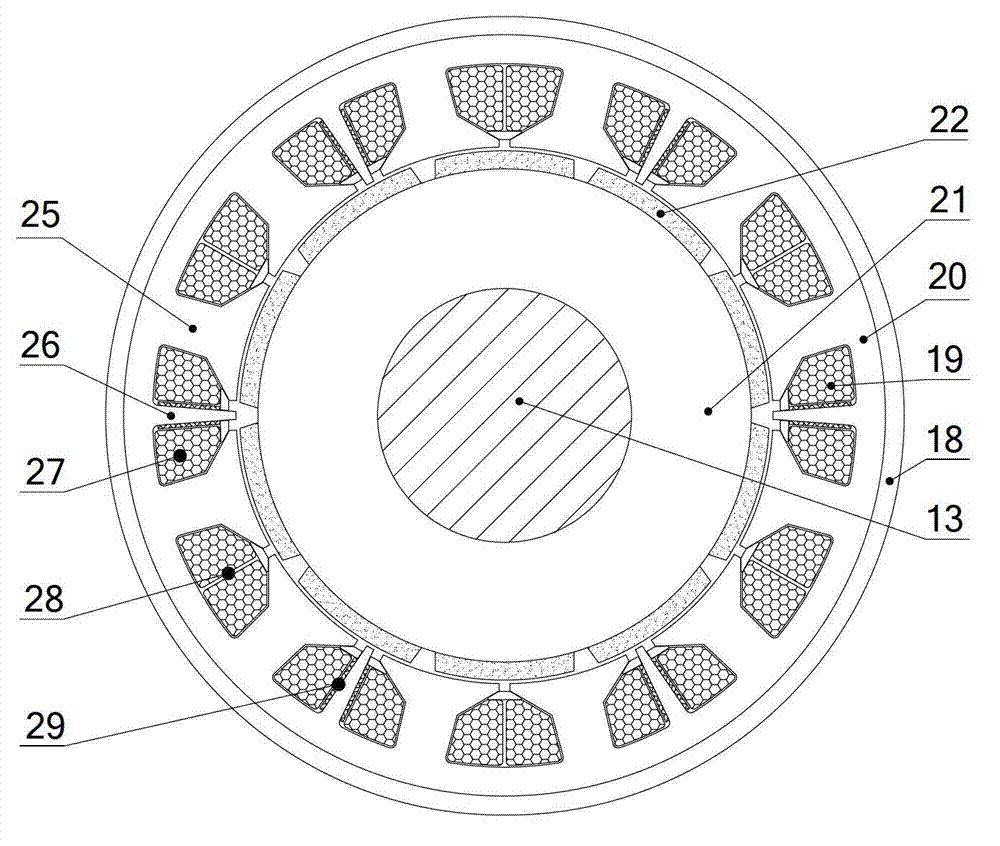

[0025] The double redundancy permanent magnet synchronous motor with low thermal coupling and no electromagnetic coupling among the windings of each phase of the present invention will be described in detail below in combination with the embodiments and the accompanying drawings.

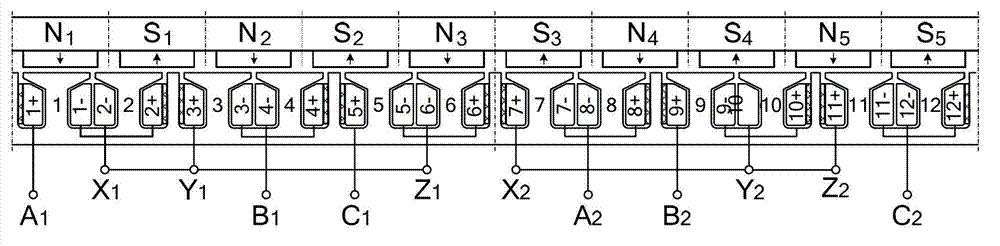

[0026] The double-redundant permanent magnet synchronous motor with low thermal coupling and no electromagnetic coupling between the windings of each phase of the present invention is mainly achieved by selecting the number Z of large teeth on the stator of the three-phase permanent magnet synchronous motor. 0 (Multi-turn coils are wound on each large tooth) and the number of pole pairs of the permanent magnet rotor p 0 Coordination between, the number of motor phases is 3, Z 0 is an even number, p 0 is an odd number, Z 0 with p 0 There is no common divisor between them, and there exists Z 0 =2p 0 The relationship of ±2; and there are 6 small teeth arranged on the stator core, and there are 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com