Zirconium oxide/resin bionic composite material for denture and preparation method thereof

A biomimetic composite material and composite material technology are applied in the field of zirconia ceramic/biocompatible resin biomimetic composite materials for dentures and their preparation, which can solve the problems of high brittleness, mismatch of hardness and modulus, and difficult processing, and achieve Good plasticity, low equipment requirements and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

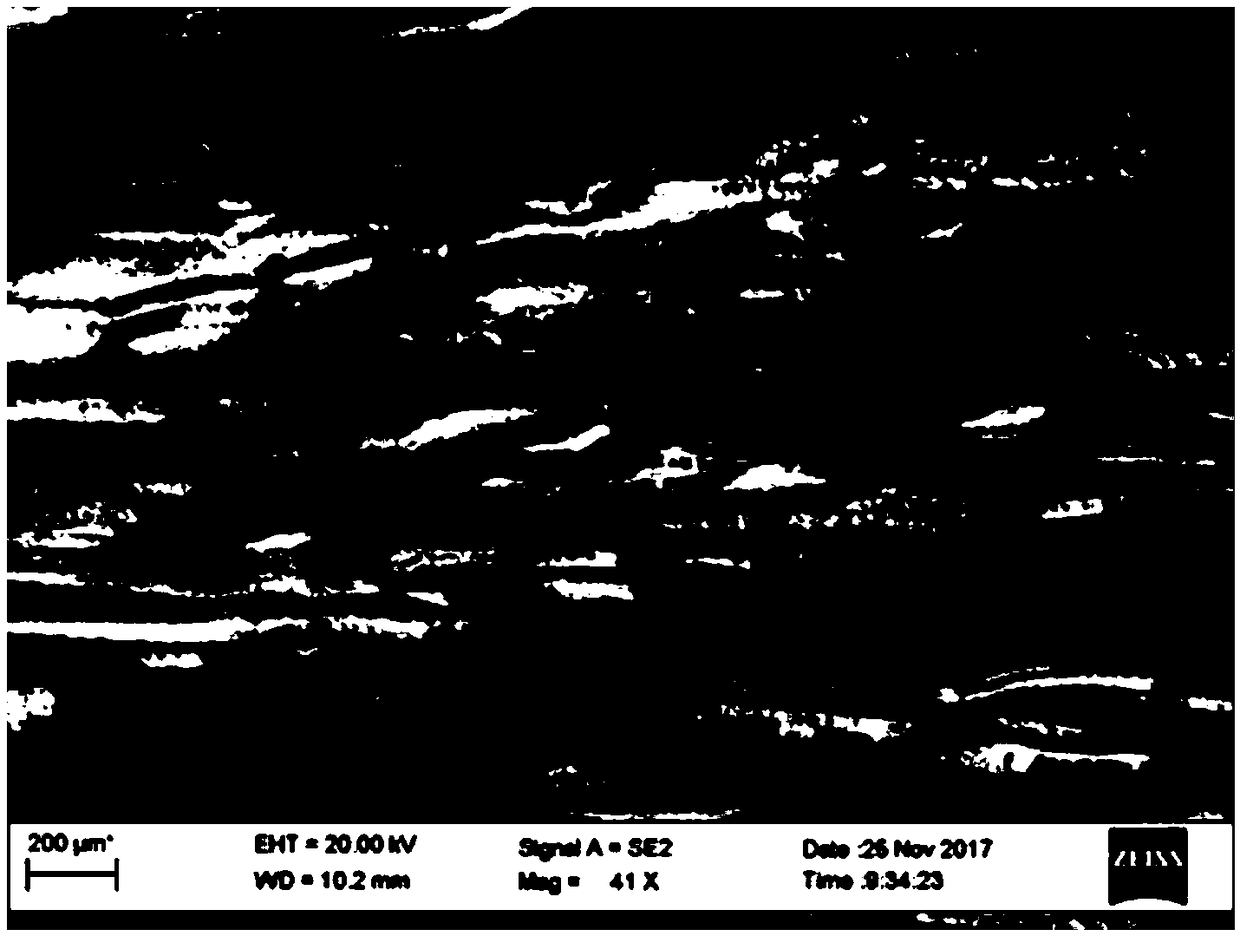

[0051] In this example, a zirconia / polymethyl methacrylate biomimetic composite material for dentures with a lamellar structure was prepared. The raw materials used mainly include yttria stabilized zirconia powder (the average particle size is 50nm), deionized water, methyl methacrylate, hydroxypropyl methylcellulose powder (the average particle size is 180μm), sucrose, polyethylene Alcohol and Darvan CN dispersant, Darvan CN dispersant is the slurry dispersant that U.S. Vanderbilt Company (R.T.Vanderbilt) produces, and concrete preparation process is as follows:

[0052] (A) Preparation of zirconia slurry

[0053] Add 130 g of deionized water into a 500 ml plastic jar, add 70 g of yttria-stabilized zirconia powder into the bottle, and stir at a speed of 60 rpm until the zirconia powder is evenly dispersed in the water. Place the jar in a constant temperature water bath at 70° C., keep it warm for 30 minutes, slowly add 0.65 g of hydroxypropyl methylcellulose powder into the ...

Embodiment 2

[0064] In this example, a zirconia / polymethyl methacrylate biomimetic composite material for dentures with a lamellar structure was prepared. The raw materials used mainly include yttria stabilized zirconia powder (the average particle size is 50nm), deionized water, methyl methacrylate, hydroxypropyl methylcellulose powder (the average particle size is 180μm), sucrose, polyethylene Alcohol and polyacrylic acid, the difference between the specific preparation process and Example 1 is that the Darvan CN dispersant is changed into polyacrylic acid, and the addition of yttrium oxide stabilized zirconia powder is changed from 70g to 150g, and all the other operations are the same as Example 1 is the same.

[0065] The zirconia / polymethyl methacrylate biomimetic composite material for dentures with lamellar structure can be prepared through the above process. After testing, the volume percentage of zirconia in the composite material is 50%, the bending strength is 230MPa, the comp...

Embodiment 3

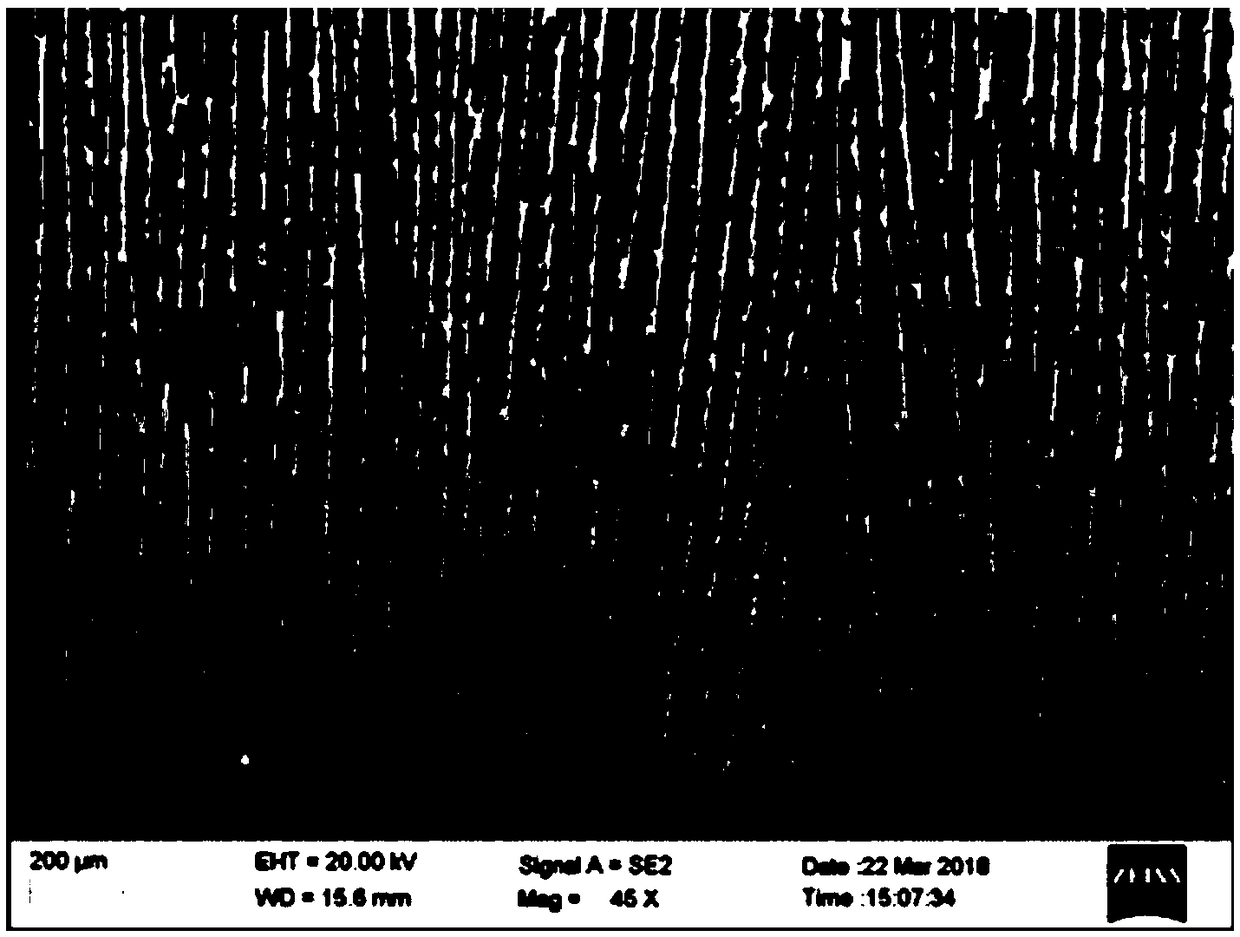

[0067] In this example, a zirconia / light-cured polymethyl methacrylate biomimetic composite material for dentures with a brick-wall structure was prepared. The raw materials used mainly include yttria-stabilized zirconia powder (the average particle size is 50nm), deionized water, methyl methacrylate containing photoinitiator, and hydroxypropyl methylcellulose powder (the average particle size is 180μm) , sucrose, polyvinyl alcohol and Darvan CN dispersant, the specific preparation process is as follows:

[0068] Get the zirconia ceramic skeleton with lamellar structure that obtains in embodiment 1 step (C), carry out the following steps successively:

[0069] (A) Vertical compression skeleton

[0070] Place the zirconia ceramic skeleton on a heating platform at 100°C, take 10g of solid paraffin and place it on the skeleton, after the paraffin melts and immerses the skeleton, place the skeleton in a steel mold, and use a hot press at 85°C along the vertical Compress the skel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com