Connecting structure of multiple eccentric shafts and synchronous driving device thereof

A technology of synchronous drive and connection structure, applied in the directions of roads, road repair, roads, etc., can solve the problems of low reliability, unapplied end face teeth or end face teeth meshing, short service life, etc., to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

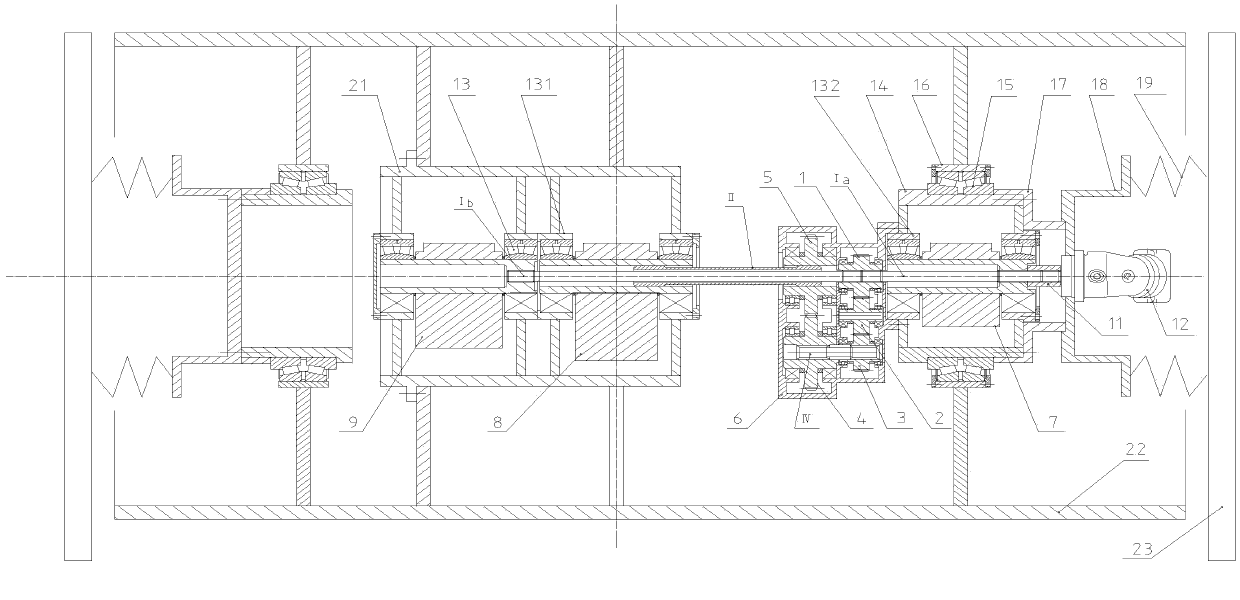

[0017] This application uses a vibrating wheel with three eccentric shafts connected in series and its double gear row synchronous reverse drive device as a typical example to illustrate.

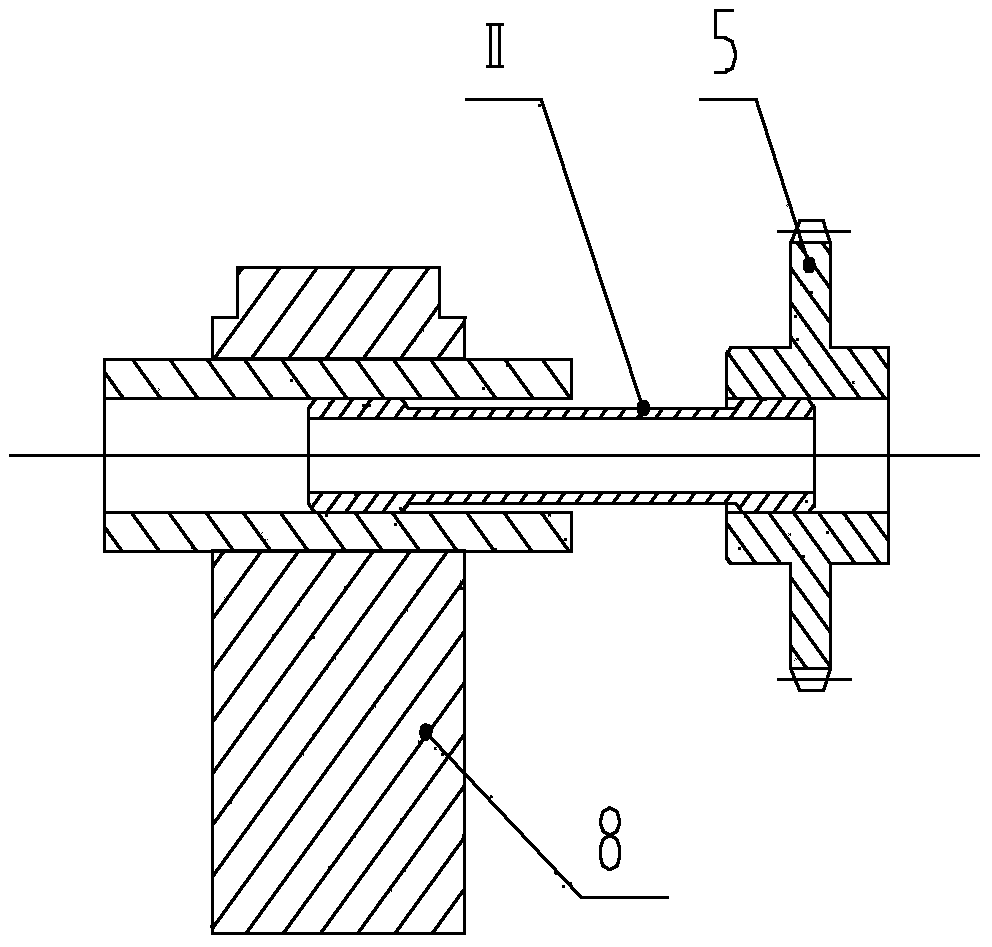

[0018] figure 1 The working process of a vibrating wheel using three eccentric shafts connected in series and its synchronous reverse drive device shown is: the vibrating motor 12 drives the first output shaft gear shaft right half shaft I through the coupling sleeve 11 a Rotation, first output shaft pinion right half shaft I a Simultaneously drive the right eccentric shaft 7, the forward output gear shaft 1, and the forward output gear shaft 1 simultaneously drives the first output shaft gear shaft left half shaft I b , The first output shaft gear shaft left half shaft I b Then drive the left eccentric shaft 9 to rotate synchronously with the right eccentric shaft 7; the forward output gear shaft 1 also drives the axle gear 2, the first synchronous gear 3, the second synchronous gear 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com