Speed and key phase integrated detection system for rotating machines

A detection system, a technology for rotating machinery, applied in the testing of mechanical components, the testing of machine/structural components, and the testing of machine gears/transmission mechanisms. To achieve the effect of easy control, wide applicability and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment approach

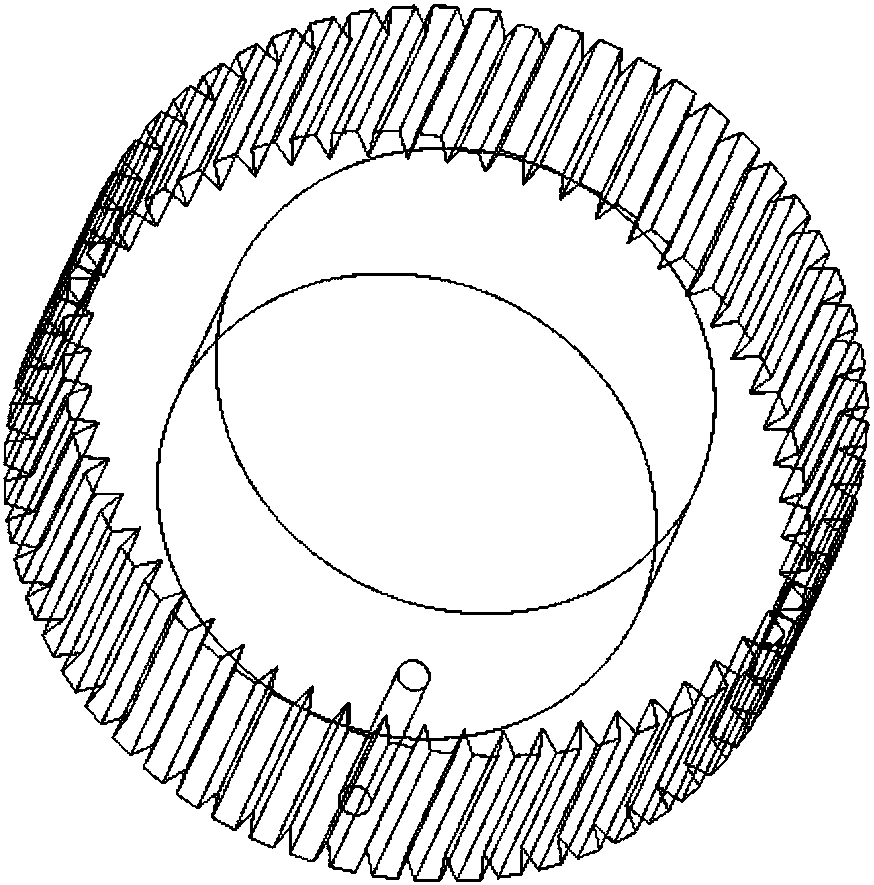

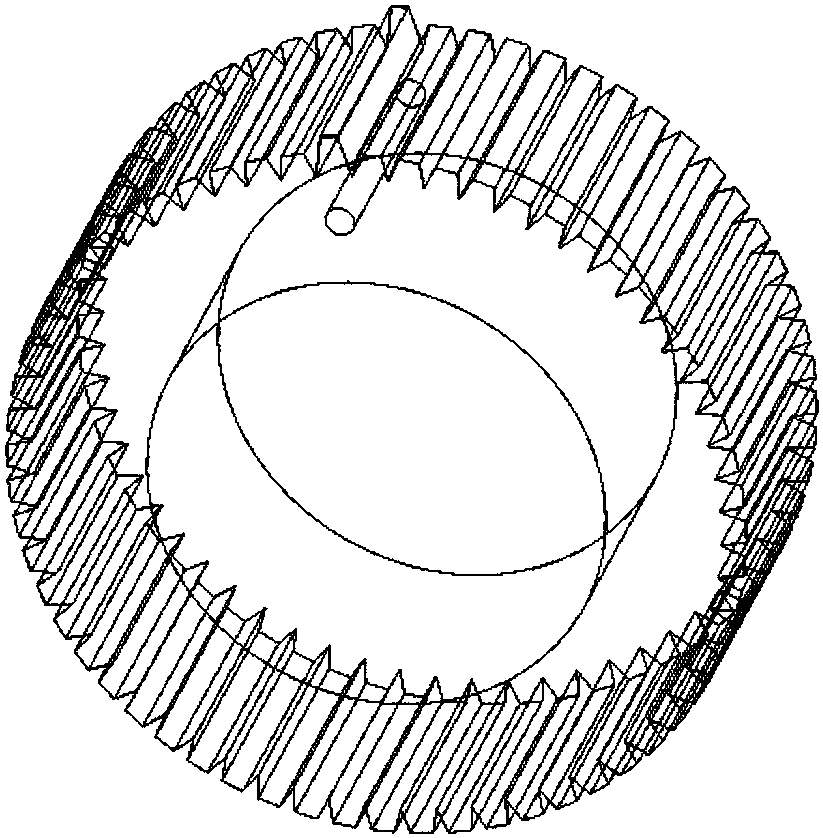

[0038] In addition, besides the way of tooth height change, the compensation tooth can also be realized in another form, and the required technical effect can also be obtained. According to another preferred embodiment of the present invention, another type of integrated detection system is also provided, which also includes a gear component, a tooth height measurement probe and a signal processing unit, and its difference mainly focuses on the design of the gear component, and other The components are largely the same. According to a preferred embodiment of the present invention, the imbalance compensation structure can be in the form of a balance hole, and the balance hole and phase teeth are designed to be distributed on both sides of the gear plate.

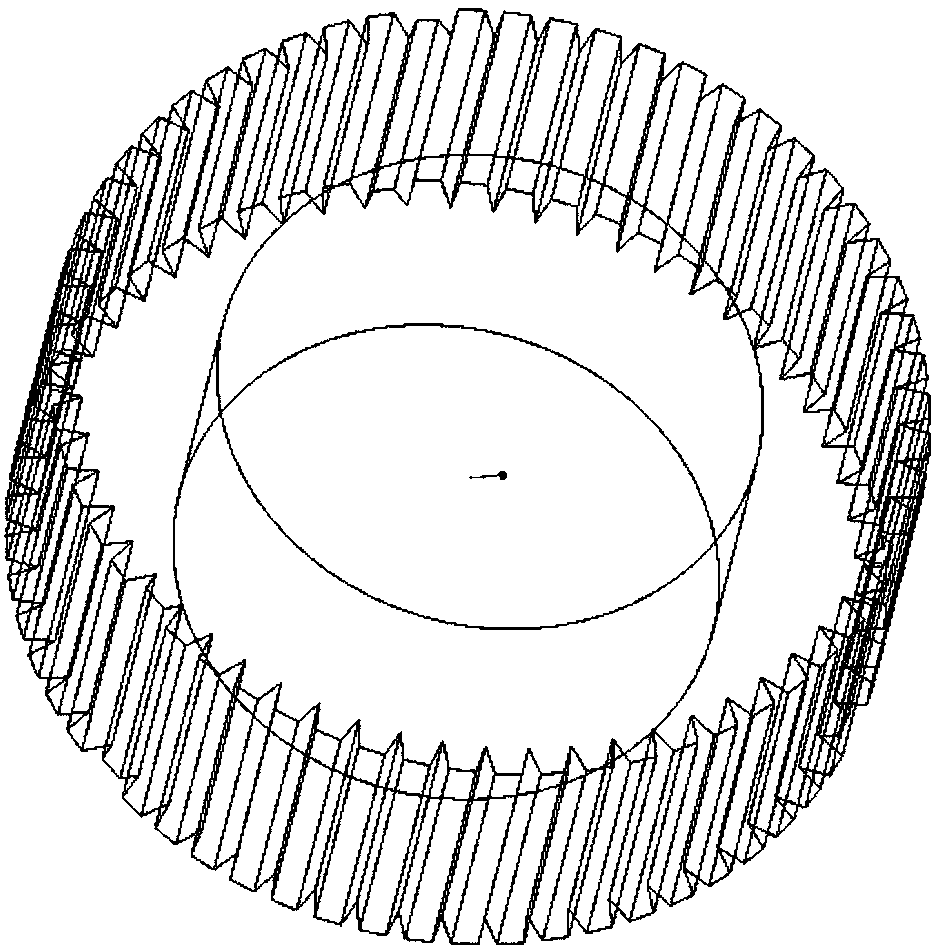

[0039] Such as Figure 2a Or as shown in 2b, the gear part is used to be concentrically fixed with the rotating element as the test object, and the rotation test is performed together; the gear part has a plurality of teeth,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com