Phase detection device and system of engine

A phase detection and engine technology, applied in engine components, engine control, machine/engine, etc., can solve problems such as affecting engine start-up performance, system safety hazards, and failing to meet the timing control requirements of 3-cylinder engines. Reduced startup time, enhanced robustness, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

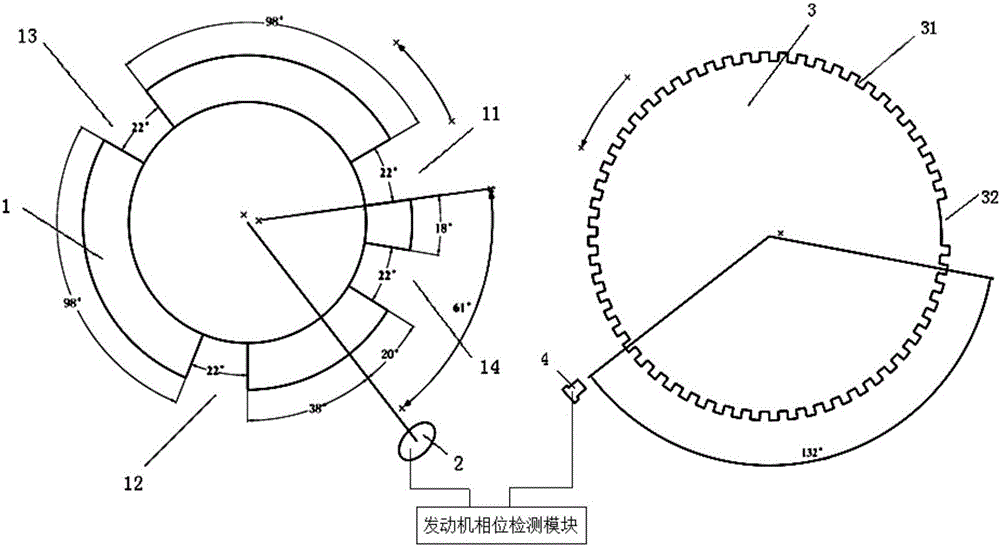

[0021] like figure 1 As shown, the engine phase detection device of the present invention includes a camshaft signal disc 1 installed and fixed on the camshaft, a first Hall sensor 2, a crankshaft signal disc 3 installed and fixed on the crankshaft, a second Hall sensor 4, and an engine Phase detection module.

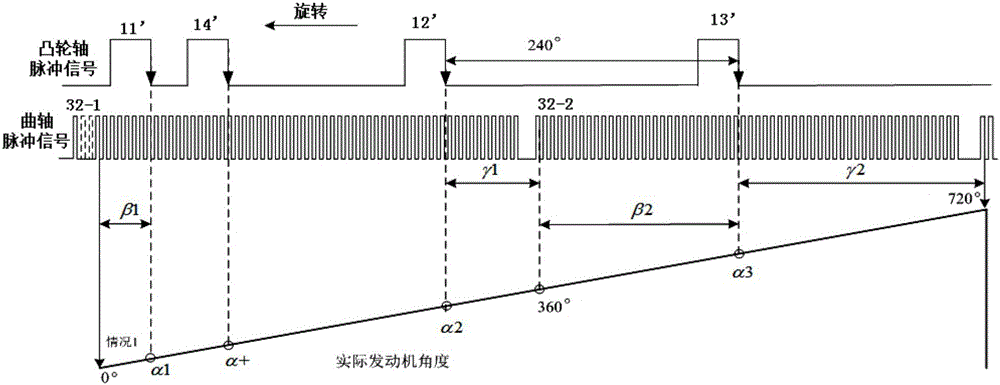

[0022] The first, second, third normal teeth 11, 12, 13 and one increased tooth 14 are distributed at equal intervals on the edge of the camshaft signal plate 1, and the increased tooth 14 is located between the first and second normal teeth 11, 12 and Close to the first normal tooth 11, each normal tooth is spaced 240° apart.

[0023] The crankshaft signal plate 3 adopts the signal form of N-α teeth (N equally spaced teeth remove the adjacent α teeth, N usually takes the equivalent value of 60, 36, and α usually takes the equivalent value of 1, 2, 3), that is, the crankshaft In addition to the evenly spaced teeth 31, there is also a missing tooth 32 on the edge of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com