Automatic nip machine for roof plate

A roof panel and automatic technology, which is applied in the manufacturing field of building material forming equipment, can solve the problems of roof panel paint strain, board type occlusion, easy escape, and poor molding effect, etc., and achieves a product that is not easy to wear, low in manufacturing cost, and stable in performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

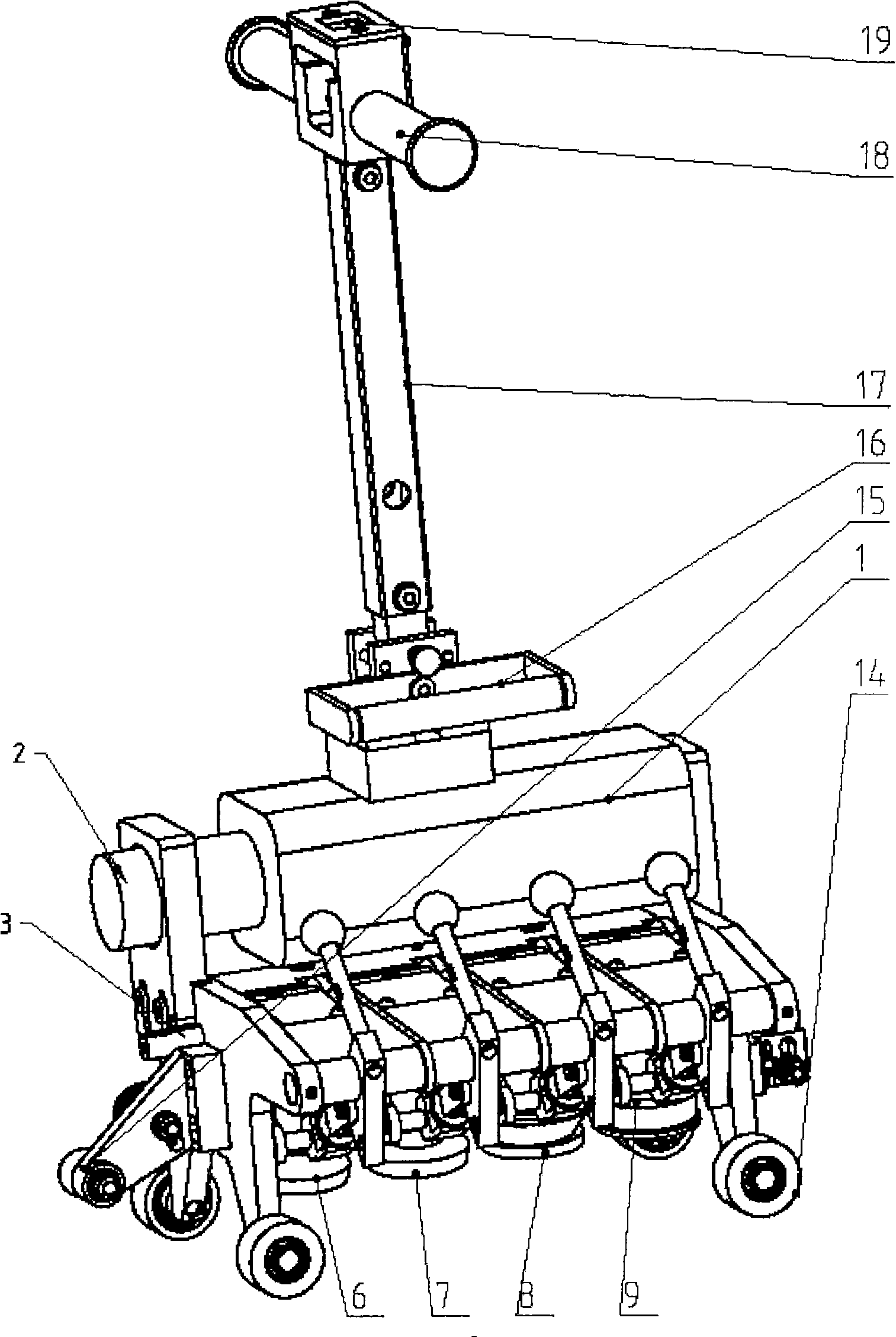

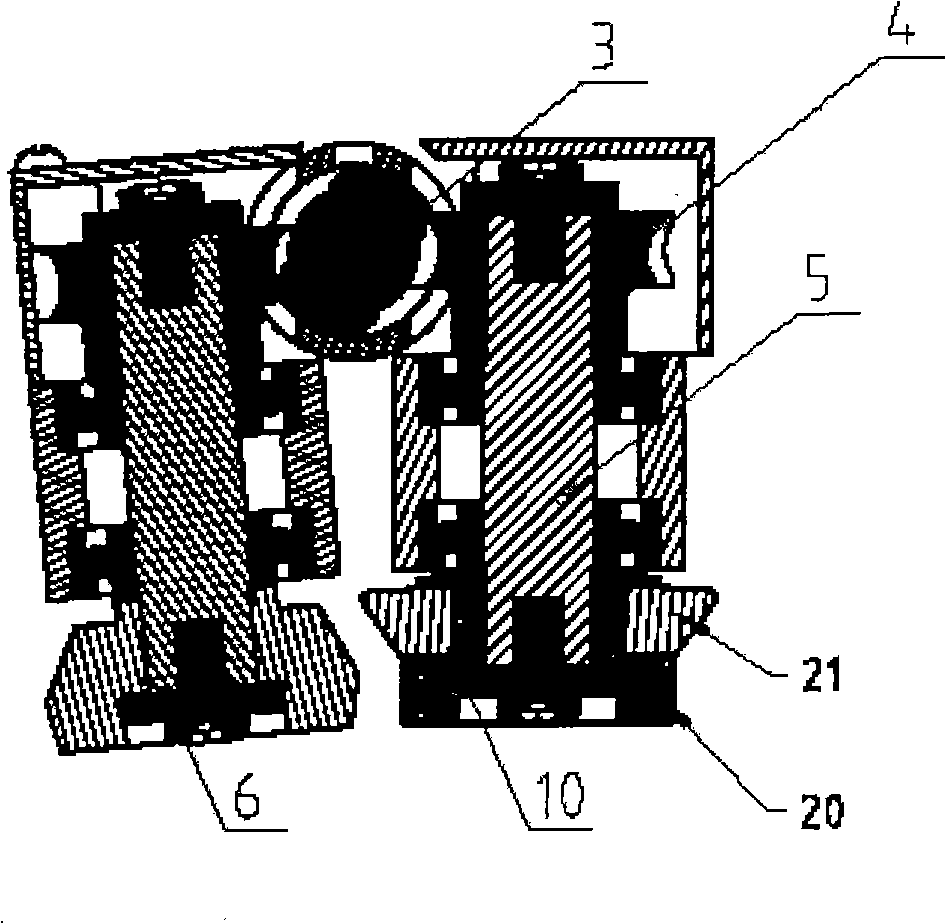

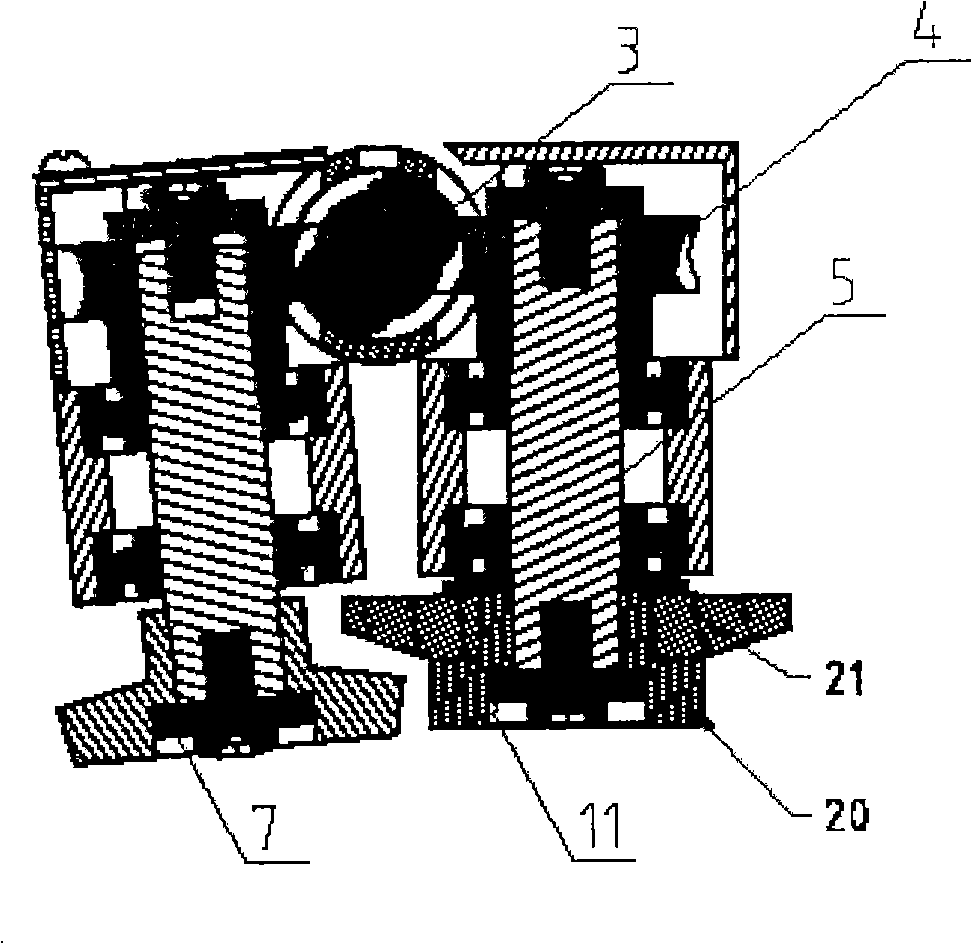

[0012] The present invention mainly consists of a motor 1 with a sprocket 2, a connecting rod 17 placed on the top of the motor 1 with a handle 16, a handle 18 placed on the top of the connecting rod 17 with a jog switch 19, a corner wheel 14 placed on the bottom of the motor 1 and The guide wheel 15, the transmission worm shaft 3 connected with the sprocket 2, and four groups of bite-forming mechanisms placed on both sides of the transmission worm shaft 3 etc.; The worm gear 4 of the shaft 5 is composed of movable wheels 6, 7, 8, 9 and fixed wheels 10, 11, 12, 13 respectively placed at the bottom of the two drive shafts 5; The wheels 10, 11 and the movable wheel 8 of the third group of interlocking forming mechanisms are also respectively provided with a differential mechanism composed of a self-wheel 20 and a differential wheel 21.

[0013] When working, hold the handle 18 and push it forward to move the corner wheel 14 to the roof panel, buckle the guide wheel 15 on the roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com