Dental implant with hydrophilic and antibacterial properties

A technology for dental implants and performance, applied in dental prosthesis, dentistry, dental implants, etc., can solve problems such as the hydrophilicity and antibacterial properties of dental implants that need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

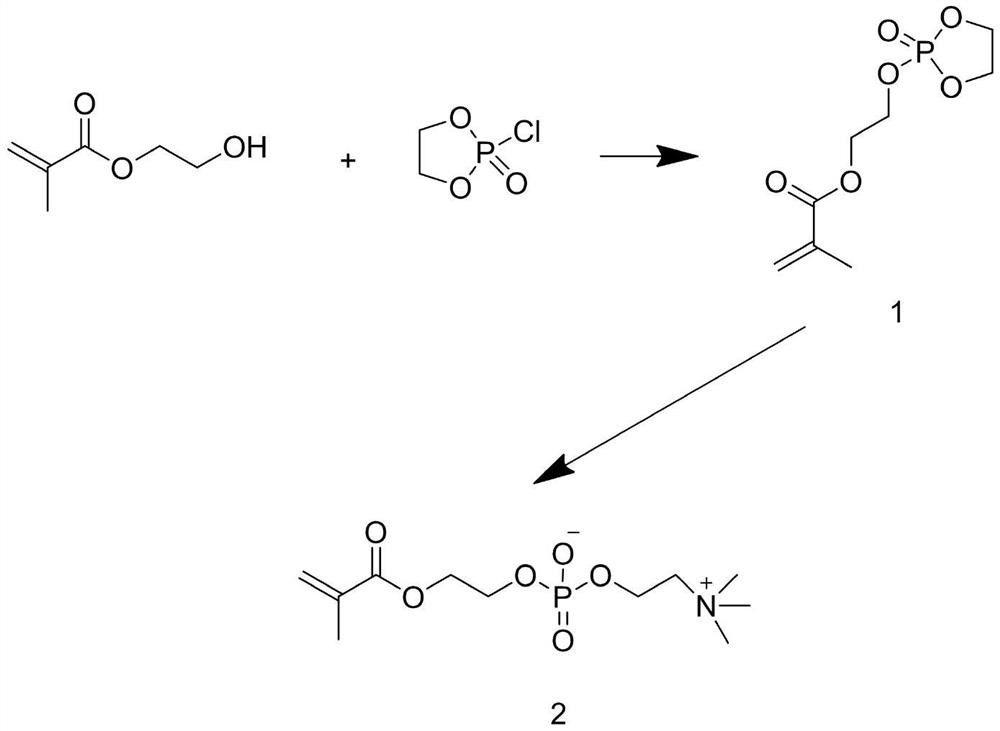

[0042] The antibacterial coating is made by the following steps:

[0043] Step S1, add 0.15mol hydroxyethyl methacrylate, 0.15mol triethanolamine and 200mL anhydrous tetrahydrofuran into the three-necked flask, stir well, add 100mL containing 0.15mol 2-chloro-2-oxo-1,3,2 - Tetrahydrofuran solution of dioxaphospholane, reflux at -20°C for 3 hours to obtain intermediate 1, raise the temperature to 60°C, add 20.45g of 70% trimethylamine solution to intermediate 1, and reflux 15h, obtain intermediate 2;

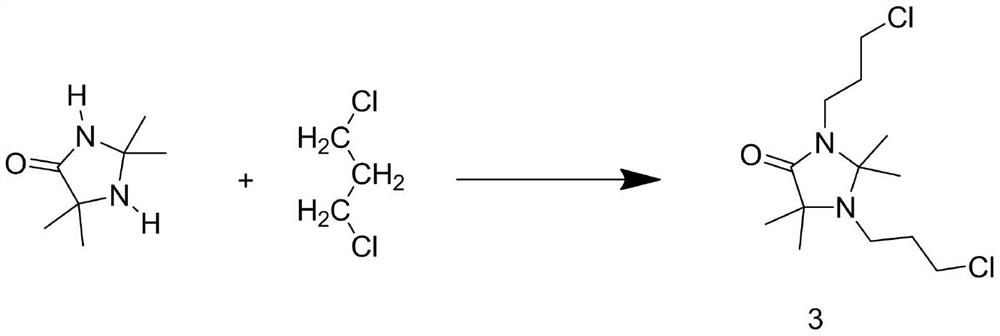

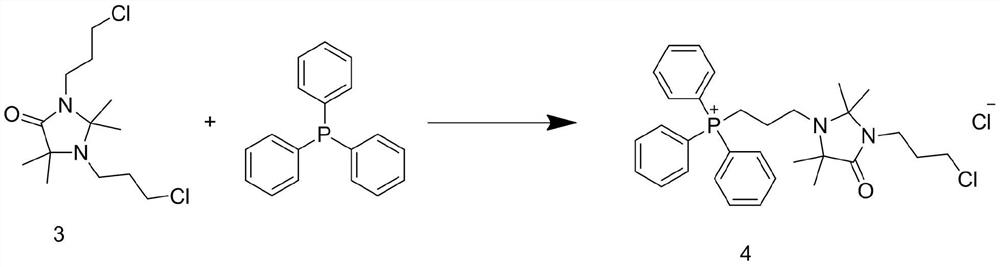

[0044] Step S2, add 3.89g of 2,2,5,5-tetramethyl-4-imidazolidinone into the flask, add 200mL of acetone, preheat the flask in an oil bath, wait until 2,2,5,5-tetramethyl After methyl-4-imidazolidinone is dissolved, add 15.6g of potassium carbonate, reflux for 40min, add 21.2g of 1,3-dichloropropane, continue to heat and reflux for 12h, distill off acetone under reduced pressure, add ethyl acetate, and then use deionized Washed twice with water to obtain intermediate 3;

[0045...

Embodiment 2

[0050] The antibacterial coating is made by the following steps:

[0051] Step S1, add 0.18mol hydroxyethyl methacrylate, 0.18mol triethanolamine and 210mL anhydrous tetrahydrofuran to the three-necked flask, stir well, add 100mL containing 0.18mol 2-chloro-2-oxo-1,3,2 - Tetrahydrofuran solution of dioxaphospholane, reflux reaction at -20°C for 4 hours to obtain intermediate 1, raise the temperature to 60°C, add 20.45g of 75% trimethylamine solution to intermediate 1, and reflux reaction 17h, intermediate 2 was obtained;

[0052] Step S2, add 3.95g of 2,2,5,5-tetramethyl-4-imidazolidinone into the flask, add 210mL of acetone, preheat the flask in an oil bath, wait for 2,2,5,5-tetra After methyl-4-imidazolidinone is dissolved, add 15.9g of potassium carbonate, reflux for 45min, add 21.8g of 1,3-dichloropropane, continue heating and reflux for 14h, distill off acetone under reduced pressure, add ethyl acetate, and then use deionized Washed 3 times with water to obtain Intermed...

Embodiment 3

[0058] The antibacterial coating is made by the following steps:

[0059] Step S1, add 0.22mol hydroxyethyl methacrylate, 0.22mol triethanolamine and 220mL anhydrous tetrahydrofuran to the three-necked flask, stir well, add 100mL containing 0.22mol 2-chloro-2-oxo-1,3,2 - Tetrahydrofuran solution of dioxaphospholane, reflux reaction at -20°C for 5 hours to obtain intermediate 1, raise the temperature to 60°C, add 20.45g of 80% trimethylamine solution to intermediate 1, and reflux reaction 20h, intermediate 2 was obtained;

[0060] Step S2, add 4.12g of 2,2,5,5-tetramethyl-4-imidazolidinone into the flask, add 220mL of acetone, preheat the flask in an oil bath, wait for 2,2,5,5-tetra After methyl-4-imidazolidinone is dissolved, add 16.2g of potassium carbonate, add 22.3g of 1,3-dichloropropane after reflux for 50min, continue heating and reflux for 16h, distill off acetone under reduced pressure, add ethyl acetate, and then use deionized Washed twice with water to obtain Inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com