Ballastless track plate and manufacturing method thereof

A technology of ballastless track and manufacturing method, which is applied in the direction of track, road, ballast layer, etc., to achieve the effect of low construction cost, low pollution, and fast and efficient interface treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

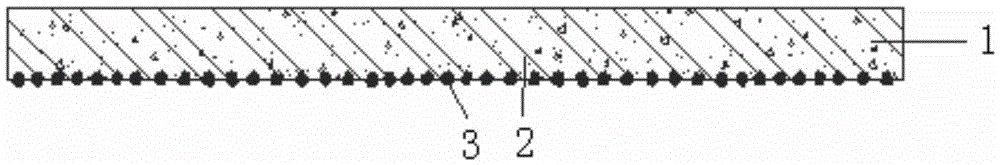

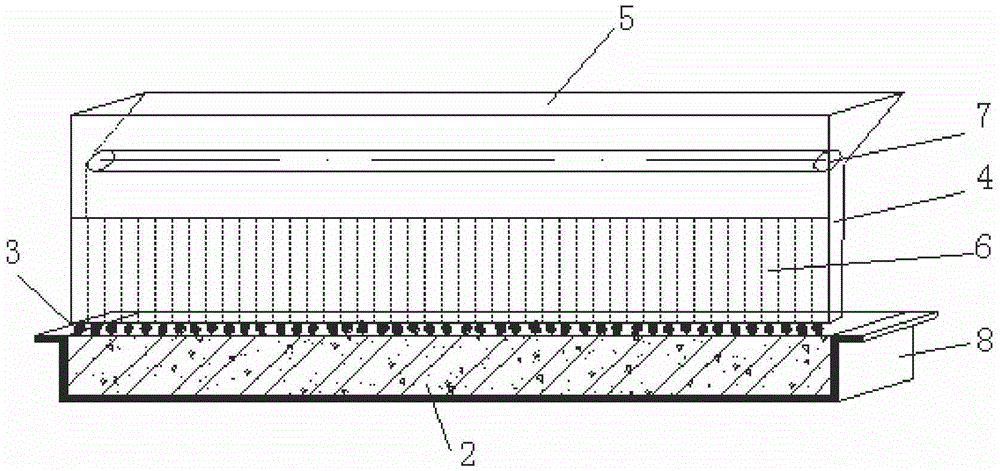

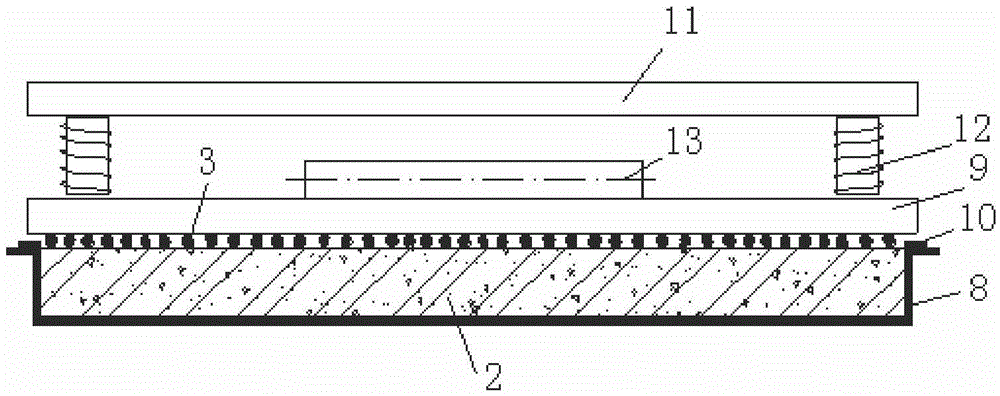

[0035] Such as figure 1 As shown, the ballastless track slab 1 in the illustration includes a concrete track slab 2 and a coarse aggregate layer 3, the concrete track slab 2 is used as the main body, and a layer of coarse aggregate is evenly fixed and implanted on the bottom surface of the concrete track slab 2, and all The coarse aggregate protrudes and exposes on the bottom surface of the concrete track slab, forming a rough coarse aggregate layer 3 .

[0036] In this embodiment, for the ballastless track slab with exposed rocks on the bottom, a layer of gravel or pebble coarse aggregate is evenly implanted on the surface of the concrete track slab 2 during the track slab inversion prefabrication process to form a coarse aggregate layer 2 Coarse aggregate layer 2 adopts crushed stone or pebble coarse aggregate, and selects a single particle size gradation within the particle size of 10-30mm; the spreading density of crushed stone or pebble coarse aggregate is 30-300kg / m 2 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com