Assembly type breakwater protective block body

A technology of breakwaters and protective blocks, applied in the direction of coastline protection, etc., can solve the problems of unfavorable integrated production, inconvenient casting mold, heavy breakwater stone, etc., and achieve the effect of simple and fast construction, fast construction and enhanced occlusal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

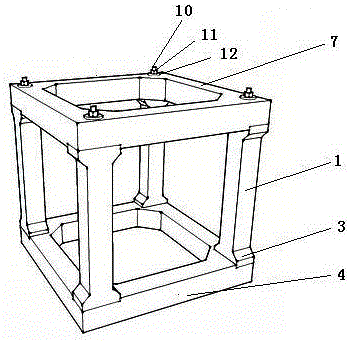

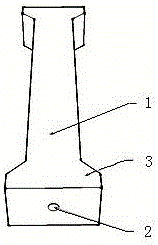

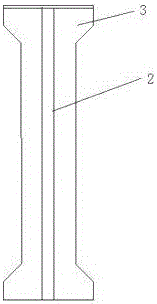

[0035] A protective block, characterized in that: such as figure 1 Shown: a prefabricated breakwater protection block, including a column (1), a reserved hole in the column center (2), a corbel (3), a prefabricated lower ring beam (4), a reserved hole for inserting reinforcement (5), The first safety limit groove (6), the prefabricated upper ring beam (7), the reserved reinforcement hole (8), the second safety limit groove (9), the end threaded anchor rod (10), the nut (11) , Large gasket (12).

[0036] Such as Figure 7 , 8 , 9, the prefabricated upper ring beam (7) is a square frame, the hollow part is a square with chamfers, and the first safety limit groove is left around, the first safety limit groove is rectangular, and the prefabricated upper ring beam (7) The long side of the safety limit groove on the same side is opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com