Anti-cold-consolidation circular pipe connecting structure

A round pipe and pipe connection technology, applied in the field of anti-cold solidification round pipe pipe connection structure, can solve the problems of flange welding and disassembly trouble, a lot of time disassembly, waste of labor cost, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

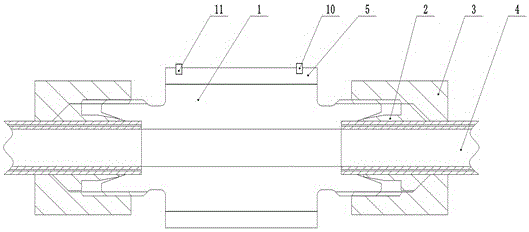

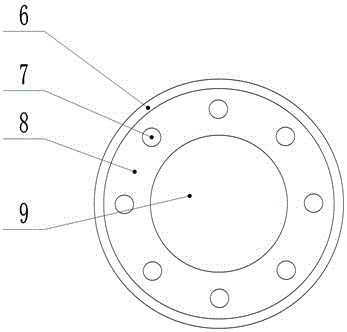

[0017] Such as figure 1 , figure 2 As shown, a pipe joint structure for anti-cold solidification, including a joint 1 with a fluid passage, a round pipe 4 connected to the fluid passage, and ferrules arranged at both ends of the joint 1; the inner end surfaces at both ends of the joint 1 are Conical surface, the outer end surface is provided with external threads; the ferrule is formed by welding the lock nut 3 and the clamp 2, and there is a gap between the lock nut 3 and the clamp 2 to be inserted into the port of the joint 1; The size of the lock nut 3 is adapted to the diameter of the outer end surface of the joint 1, and has an internal thread that engages with the outer thread of the outer end surface of the joint 1; the clamp 2 is arranged between the lock nut 3 and the joint 1, and An intubation through hole adapted to the diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com