Micro-prism monomer reflective waterproof zipper and manufacturing method thereof

A waterproof zipper and the technology of its manufacturing method, applied in the field of zippers, can solve the problems of broken glass beads, high production cost of chain belts, dull and inconspicuous colors, etc. Reflective performance, waterproof and not easy to attach dust particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

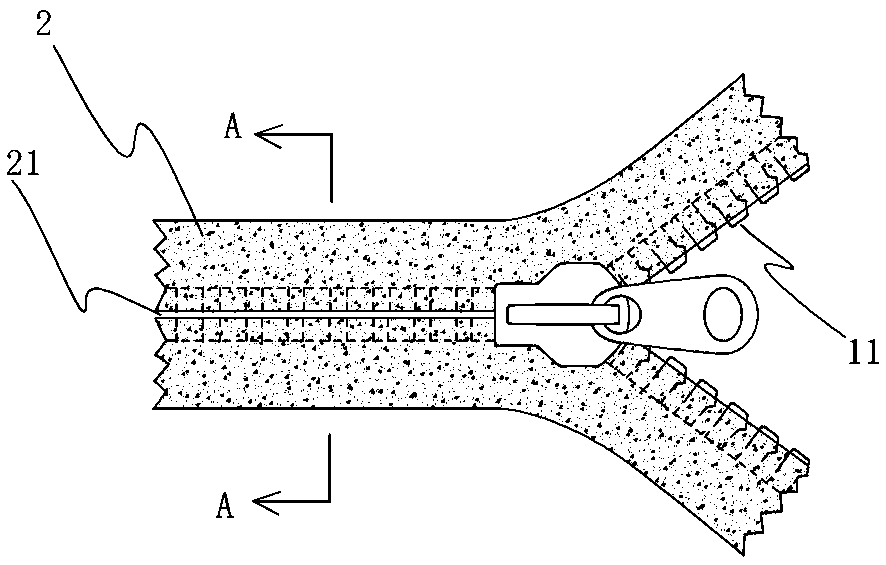

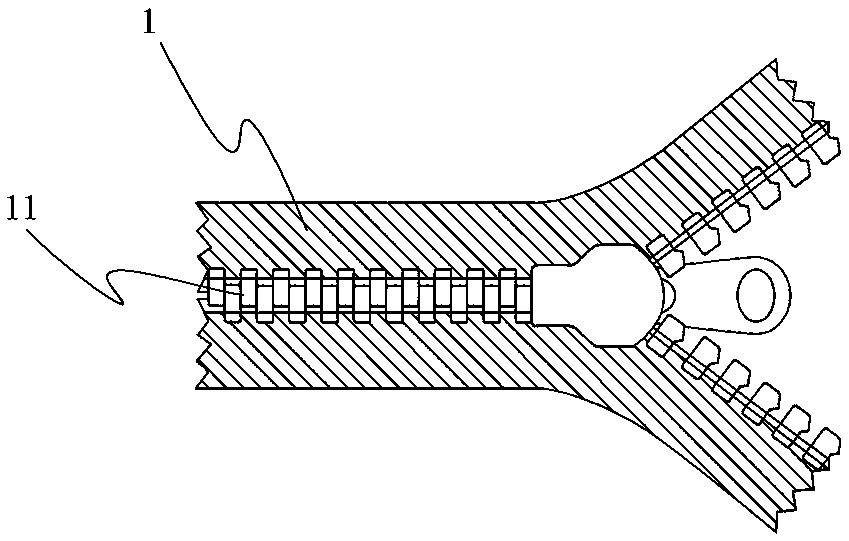

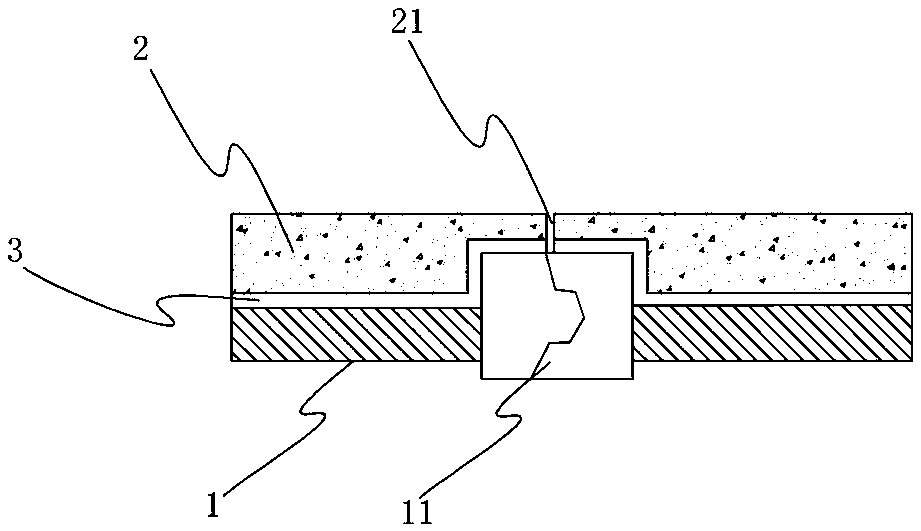

[0033] refer to Figure 1-3 , the embodiment of the present invention discloses that a microprism monomer reflective waterproof zipper includes a zipper body 1, the zipper body 1 is provided with chains 11 that can be engaged and separated from each other, and the zipper body 1 is provided with a reflective Waterproof adhesive film 2, a hot-melt adhesive composite layer 3 is provided between the reflective waterproof adhesive film 2 and the zipper body 1; the reflective waterproof adhesive film 2 covers the chain, and the reflective waterproof adhesive film 2 is provided with Longitudinal slit 21, the longitudinal slit 21 extends along the length direction of the chain, the longitudinal slit is closed when the chain is engaged, and the longitudinal slit is opened when the chain is separated; The transparent adhesive film that the hot-melt adhesive r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com