Construction method of hand-dug piles

A technology of artificial digging piles and construction methods, which is applied to sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of slow construction organization, large material input, complex construction technology, etc., and achieves guaranteed construction progress and construction management. Simple, simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

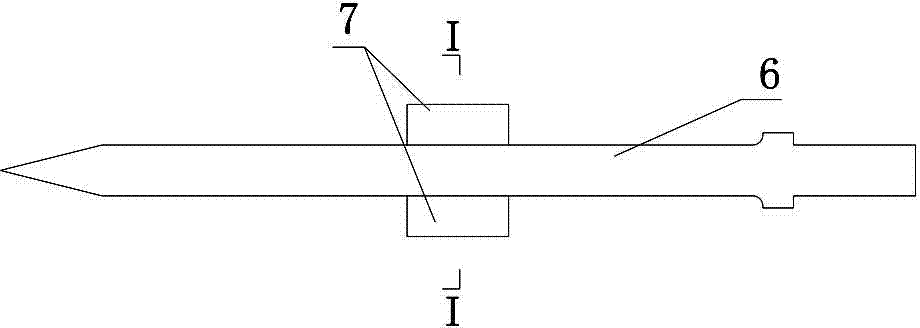

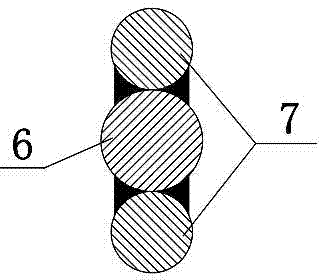

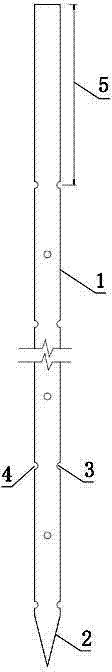

[0030] Such as Figure 1-6 Shown, the manual hole-digging pile construction method of the present invention is carried out according to the following steps;

[0031] The first step: construction preparation

[0032] 1. Leveling, clearing of sundries in the excavation site, ramming and compacting. Excavation of drainage ditches in the site. Clean up surface water. The total station accurately stakes out the hole pile position, sets up the protective pile, checks the pile position and the verticality of the excavated hole at any time, etc.; installs the manual digging pile lifting equipment, sets the surrounding fence, and arranges the slag discharge road;

[0033] 2. Place the water tank to prepare enough water for construction, and arrange the circuit reasonably to meet the construction needs;

[0034] 3. Prepare grouting equipment, including one YSH-3 single-piston grouting machine, one double 200L layer cement slurry mixer, one 2-inch cement slurry delivery hose, 3m 3 O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com