Construction method for grouting reinforced region applied to water-rich sand layer shield tunnel

A technology of grouting reinforcement and shield tunneling, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve the problems of increased grouting costs, high construction operation requirements, and easy blockage of grout pipes, etc., to improve the bearing capacity of surrounding rocks capacity, improving construction quality, and reducing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

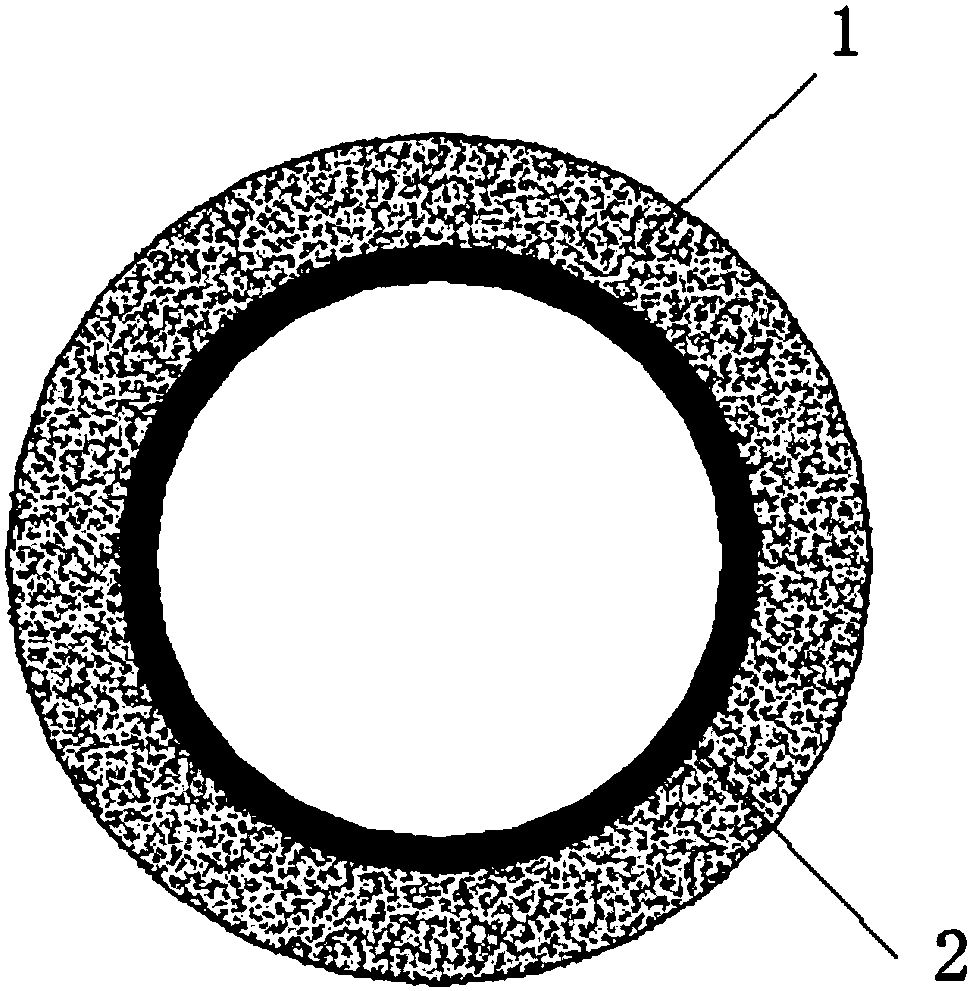

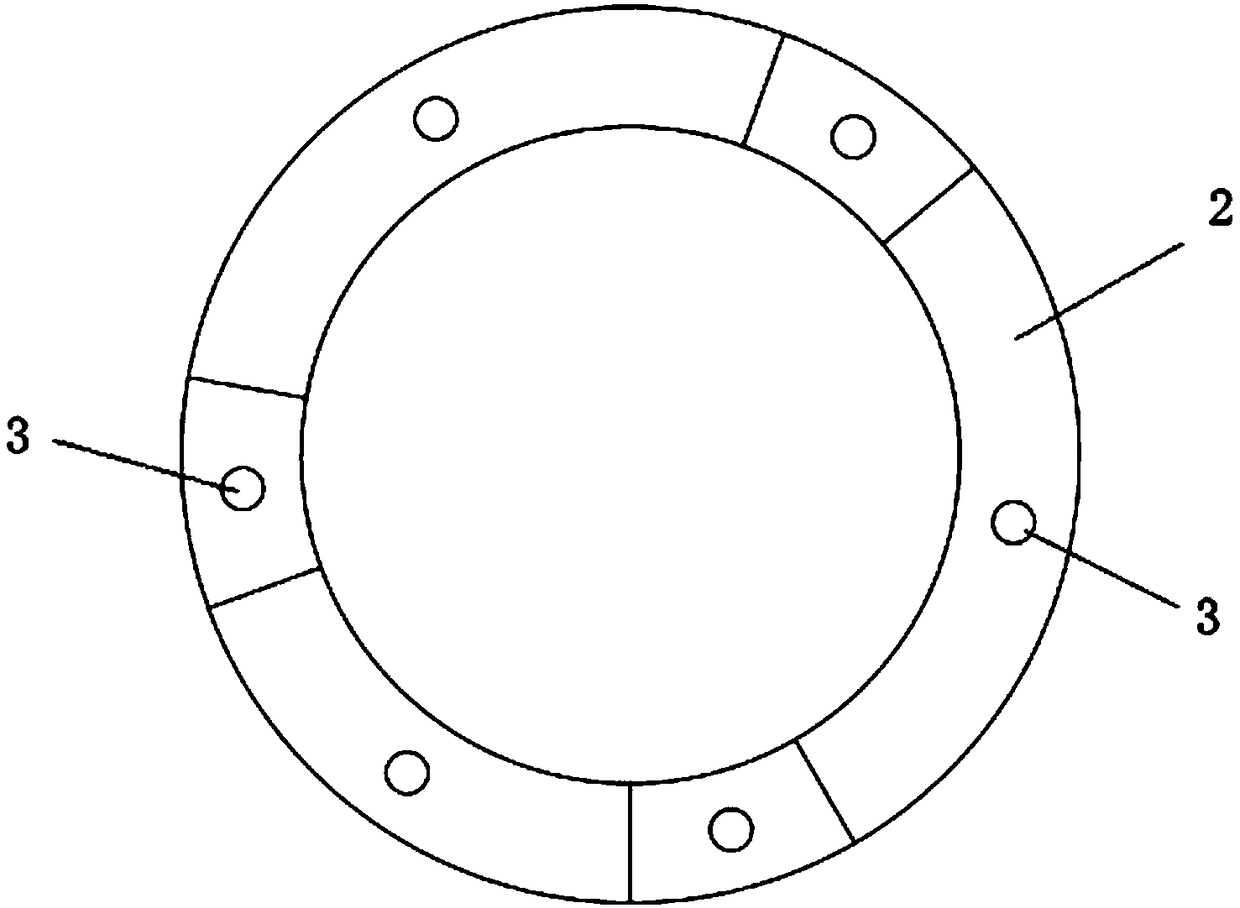

[0045] like figure 1 , 2 As shown, a construction method applied to the grouting reinforcement ring of the water-rich sand layer shield tunnel includes the following steps:

[0046] A) Determine the parameters of the grouting reinforcement ring 1 and the grouting control mode, including the following steps:

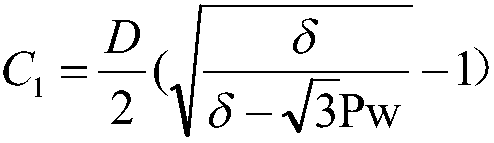

[0047] 1) Calculate and determine the thickness of the grouting reinforcement ring 1, the formula is as follows:

[0048]

[0049] In the formula, C 1 is the thickness of the grouting surrounding rock reinforcement circle 1, D is the equivalent diameter of the tunnel excavation, δ is the allowable compressive strength of the lining surrounding rock reinforcement, and Pw is the maximum hydrostatic pressure value of the surrounding rock;

[0050] Calculate the thickness of the grouting reinforcement ring 1 to be 1.5m;

[0051] 2) Determine the grouting pressure according to the hydrostatic pressure measured in the tunnel, and its value is 0.2-0.4MPa;

[0052] 3) Det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com