Sealing equipment and construction technology of lng full-contained tank vault air blowing jacking process

A sealing device and air blowing technology, applied in mechanical equipment, engine sealing, fixed-capacity gas storage tanks, etc., can solve problems such as insufficient rubber plate support, cumbersome installation of steel gussets, material consumption and waste, and achieve easy installation Dismantling, sealing effect is remarkable, and the effect of reducing the amount of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

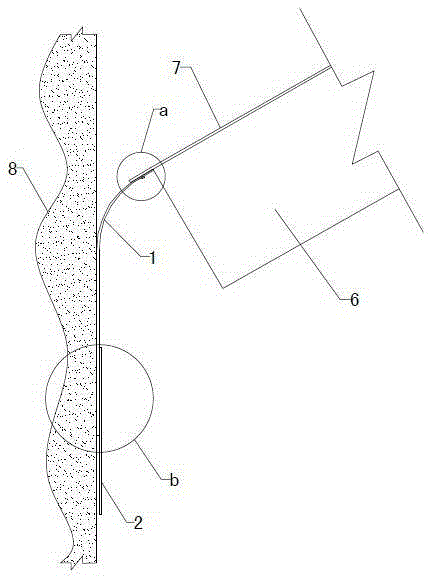

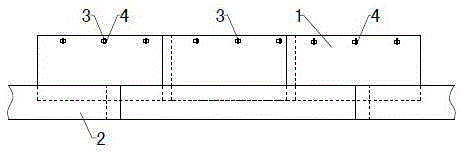

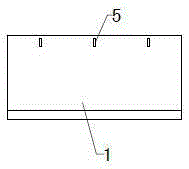

[0031] 1) Install the main sealing plate: multiple sheets of galvanized iron sheets with a specification of 1442mm×700mm are determined as the main sealing plate 1, and the lower edge of the main sealing plate 1 is bent inward by 12o with a bending width of 10mm. Set up fixing holes 5 on the upper edge of the main sealing plate 1, the distance between the fixing holes 5 is 447mm, use the gantry plate 3 and wedge 4 to fix the main sealing plate 1 on the lower surface of the tank top skin plate 7 at the position of the fixing holes 5 After the fixation is completed, spot weld the wedge 4 on the skin plate 7; then install the main sealing plate 1 one by one in sequence, and the overlap between the main sealing plates 1 is 110mm to ensure a tight connection between the two; then use the sealing Glue seals the gap between the main seal plate 1 connections.

[0032] 2) Install the auxiliary sealing plate: After the main sealing is completely installed, stick the auxiliary sealing so...

Embodiment 2

[0035] 1) Install the main sealing plate: multiple sheets of galvanized iron sheets with a specification of 1442mm×700mm are determined as the main sealing plate 1, and the lower edge of the main sealing plate 1 is bent inward by 12o with a bending width of 10mm. Set up fixing holes 5 on the upper edge of the main sealing plate 1, the distance between the fixing holes 5 is 447mm, use the gantry plate 3 and wedge 4 to fix the main sealing plate 1 on the lower surface of the tank top skin plate 7 at the position of the fixing holes 5 After the fixation is completed, spot-weld the wedges 4 on the skin plate 7; then install the main sealing plates 1 one by one in turn, and the overlap between the main sealing plates 1 is 100 mm to ensure a tight connection between the two; then use the sealing Glue seals the gap between the main seal plate 1 connections.

[0036] 2) Install the auxiliary sealing plate: After the main sealing is completely installed, stick the auxiliary sealing sof...

Embodiment 3

[0039] 1) Install the main sealing plate: multiple sheets of galvanized iron sheets with a specification of 1442mm×700mm are determined as the main sealing plate 1, and the lower edge of the main sealing plate 1 is bent inward by 12o with a bending width of 10mm. Set up fixing holes 5 on the upper edge of the main sealing plate 1, the distance between the fixing holes 5 is 447mm, use the gantry plate 3 and wedge 4 to fix the main sealing plate 1 on the lower surface of the tank top skin plate 7 at the position of the fixing holes 5 After the fixation is completed, spot weld the wedge 4 on the skin plate 7; then install the main sealing plate 1 one by one in sequence, and the overlap between the main sealing plates 1 is 110mm to ensure a tight connection between the two; then use the sealing Glue seals the gap between the main seal plate 1 connections.

[0040] 2) Install the auxiliary sealing plate: After the main sealing is completely installed, stick the auxiliary sealing so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com