Flue modification method and flue anticorrosive structure

A technology for flue, thermal insulation and anti-corrosion layer, applied in combustion method, combustion product treatment, exhaust gas device and other directions, can solve problems such as flue corrosion and damage, achieve economical cost, change flue layout, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

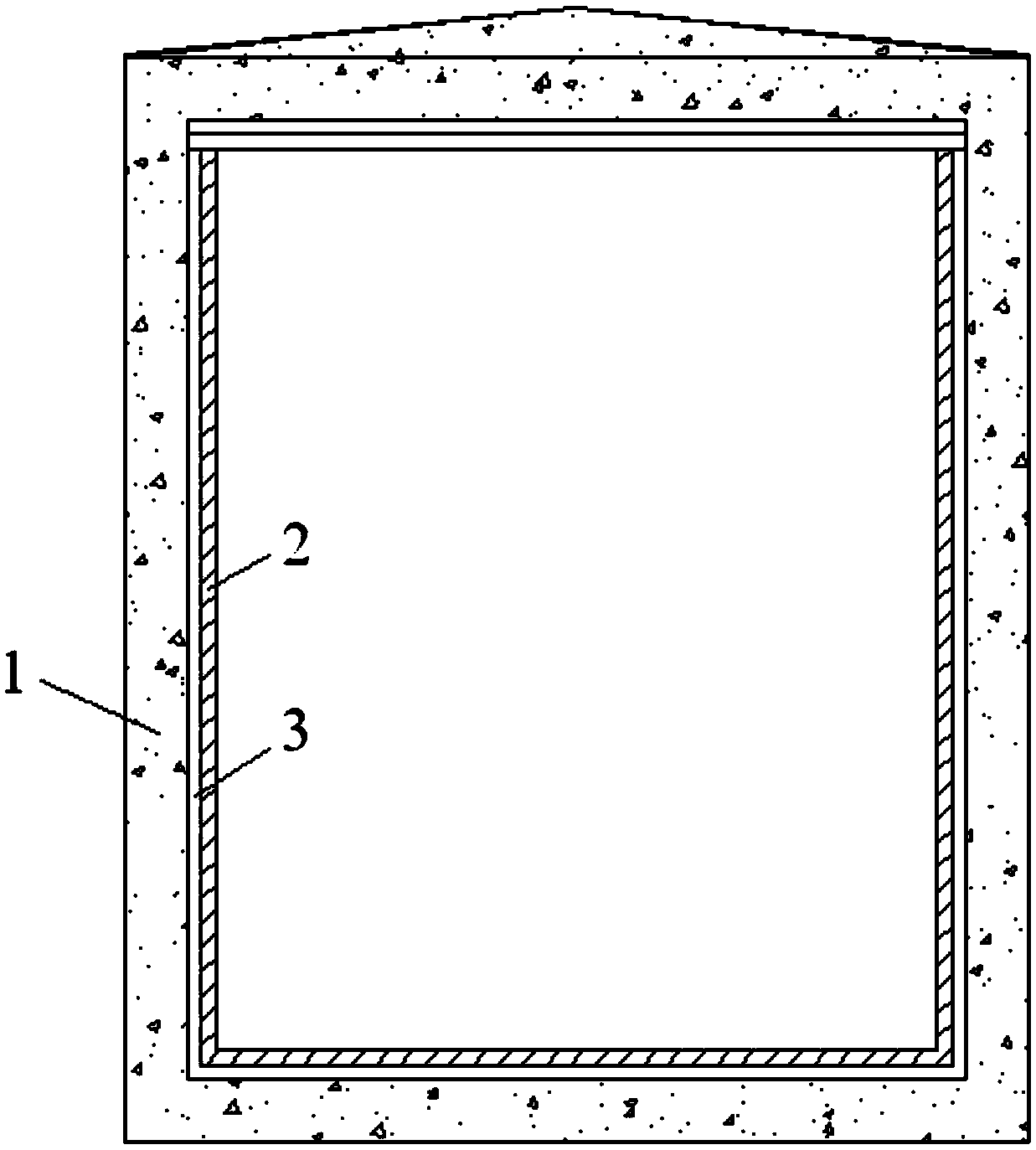

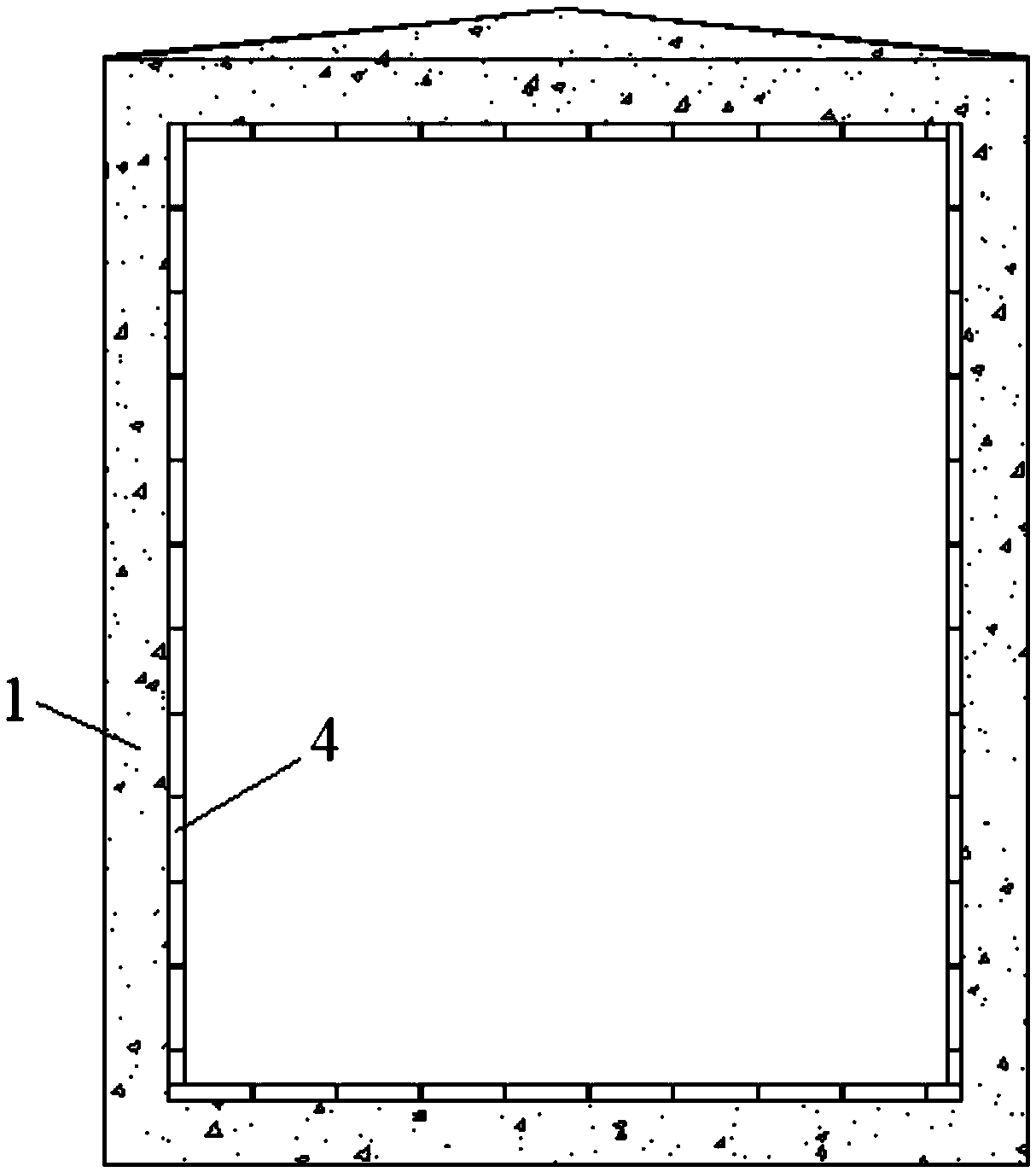

[0023] like figure 2 As shown, it is a flue anticorrosion structure provided by the present invention, which includes a flue casing 1, the inner wall surface of the flue casing 1 is covered with a heat preservation and anticorrosion layer 4, and the heat preservation and anticorrosion layer 4 includes The primer layer on the surface of the inner wall of the casing 1 and the glass brick fixed on the primer layer by an adhesive; the pit of the local defect on the inner wall of the flue casing 1 is provided with a repair layer 5 .

[0024] The above-mentioned flue anticorrosion structure is based on the transformation method of the existing concrete (brick) flue:

[0025] Remove the original heat insulation layer 3 and inner lining layer 2 of the flue shell 1, sandblast, polish and partially repair the inner wall of the flue shell 1, and repair the local defect pits on the inner wall of the flue shell 1 Carry out repairs to form a repair layer 5; then, paint a primer layer on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com