Fining twisted steel-based lifting appliance and lifting method thereof

A technology of fine-rolled rebar and hoisting method, which is applied in the direction of hoisting devices, etc., which can solve problems such as troublesome operation, short screw length, and small space where hoisting equipment cannot be installed, so as to achieve the effects of convenient interception, reduced consumption, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

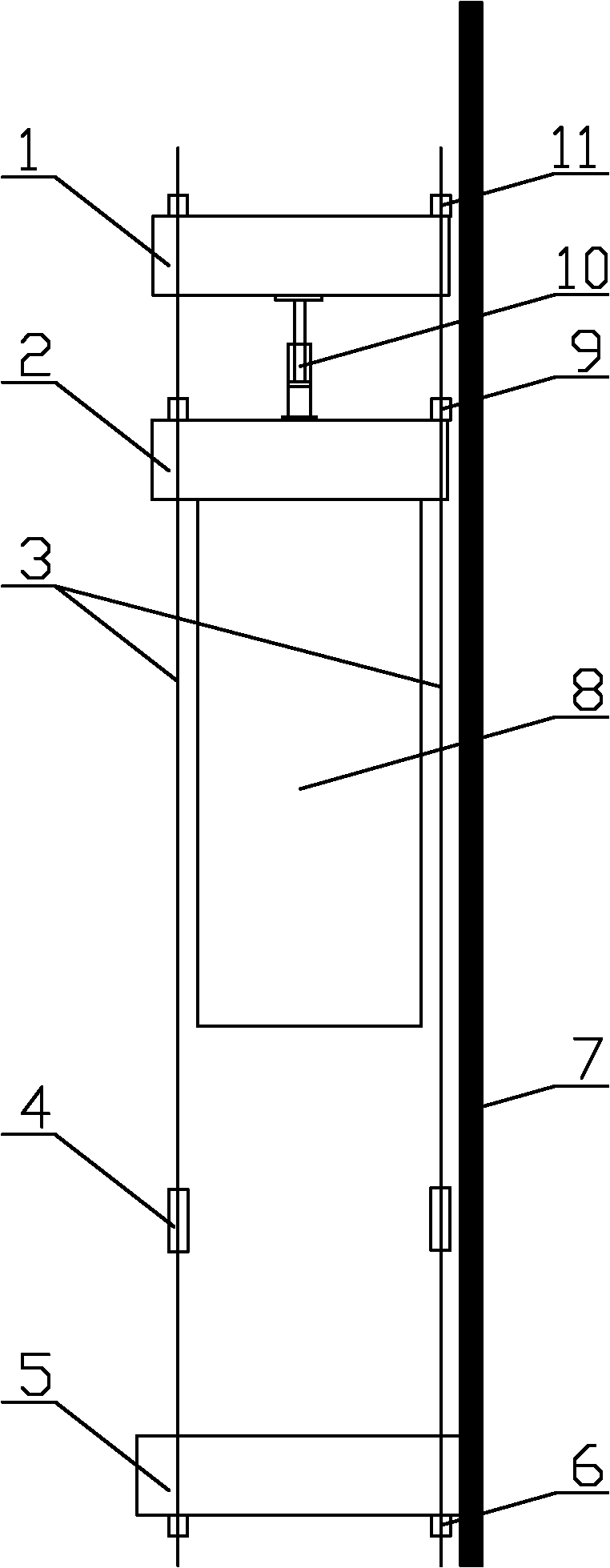

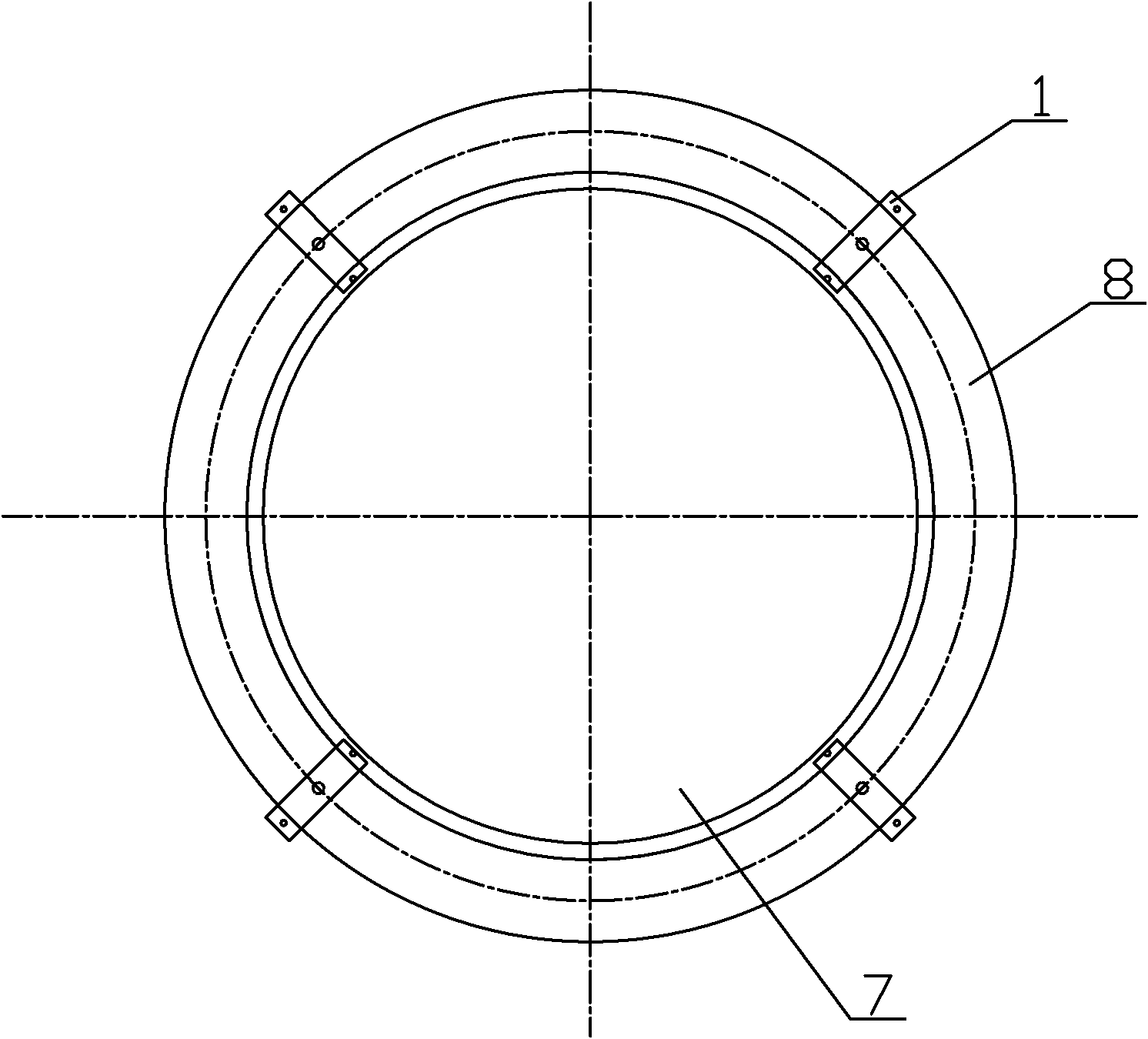

[0027] During the upside-down construction of the 100-ton converter shell 7 of Ronggang 3#, since the gap between the furnace shell 7 and the support ring 8 is very narrow, (6290-5990) / 2=150mm, construction methods such as winches cannot be used. The center-through hydraulic jack 10 cannot be placed, but the finish-rolled rebar 3 can be placed, so the finish-rolled rebar 3 is used as the spreader.

[0028] Such as figure 1 and figure 2 As shown, the specific upgrading process is as follows:

[0029] Four lifting points are set on the periphery of the furnace shell 7, and each lifting point bears a load of 132.4 / 4=34.1 tons. According to the size of the outer diameter of the furnace shell 7, the number of hanging points can be changed.

[0030] In this embodiment, the furnace shell 7 is the object to be hoisted, and the support ring 8 is the fixed reference object. At this time, the furnace shell 7 and the support ring 8 are in an upside-down state. The first fixed crossbe...

Embodiment 2

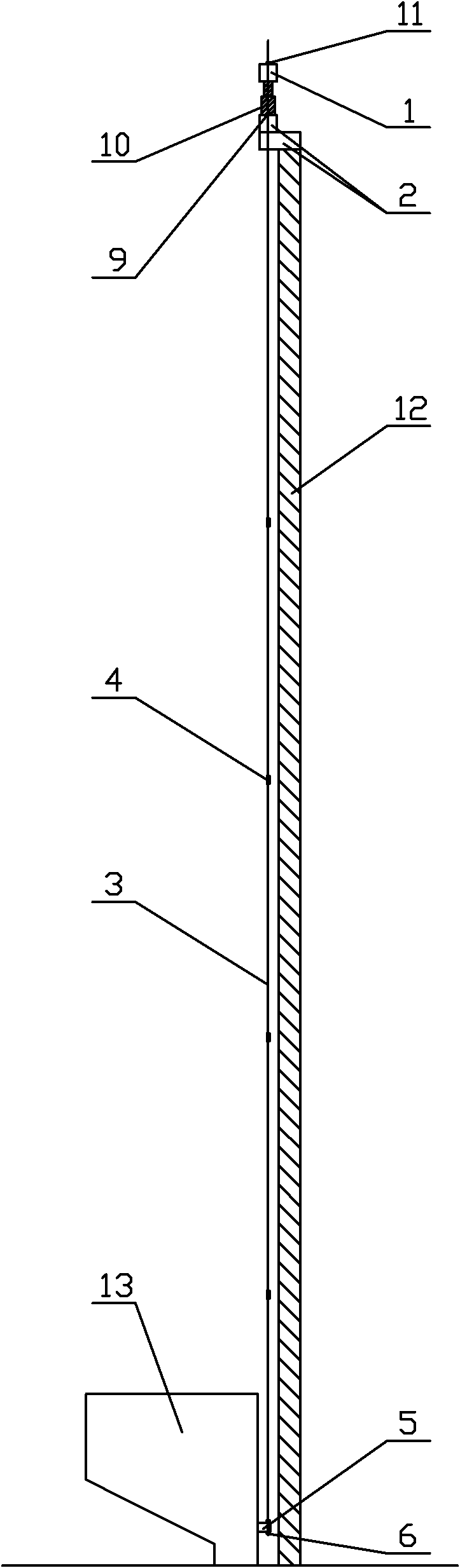

[0036] Such as Figure 3 to Figure 5 As shown, the water tank 13 of the outer water tower of the first-phase steelmaking workshop of Ronggang is on the top of the tower body 12, the height of the tower body 12 is 78 meters, and the water tank 13 is a concrete structure.

[0037] The existing technology is to prefabricate the water tower 13 at the bottom of the tower body 12, and then use carefully processed 3-meter-long round steel to make a threaded screw. The screw is connected by a connector, and then the hydraulic synchronization system is used for lifting. Since the screw rod and connector need to be specially processed, and the length of the screw rod is relatively short, the lifting group needs to be replaced every 3 meters during the lifting process, and the lifting speed is very slow.

[0038] The present invention adopts the 12-meter-long finish-rolled rebar and the anchor as the lifting tool, and the lifting group can be replaced every 12 meters.

[0039] In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com