Water-stopping form board

A formwork and water-stop technology, which is applied in the direction of formwork/formwork components, formwork/formwork/work frame, water conservancy projects, etc., can solve the problems of poor water-stop effect, difficult installation, and material consumption, so as to avoid difficult compaction , Improve the quality of pouring, improve the effect of water stop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

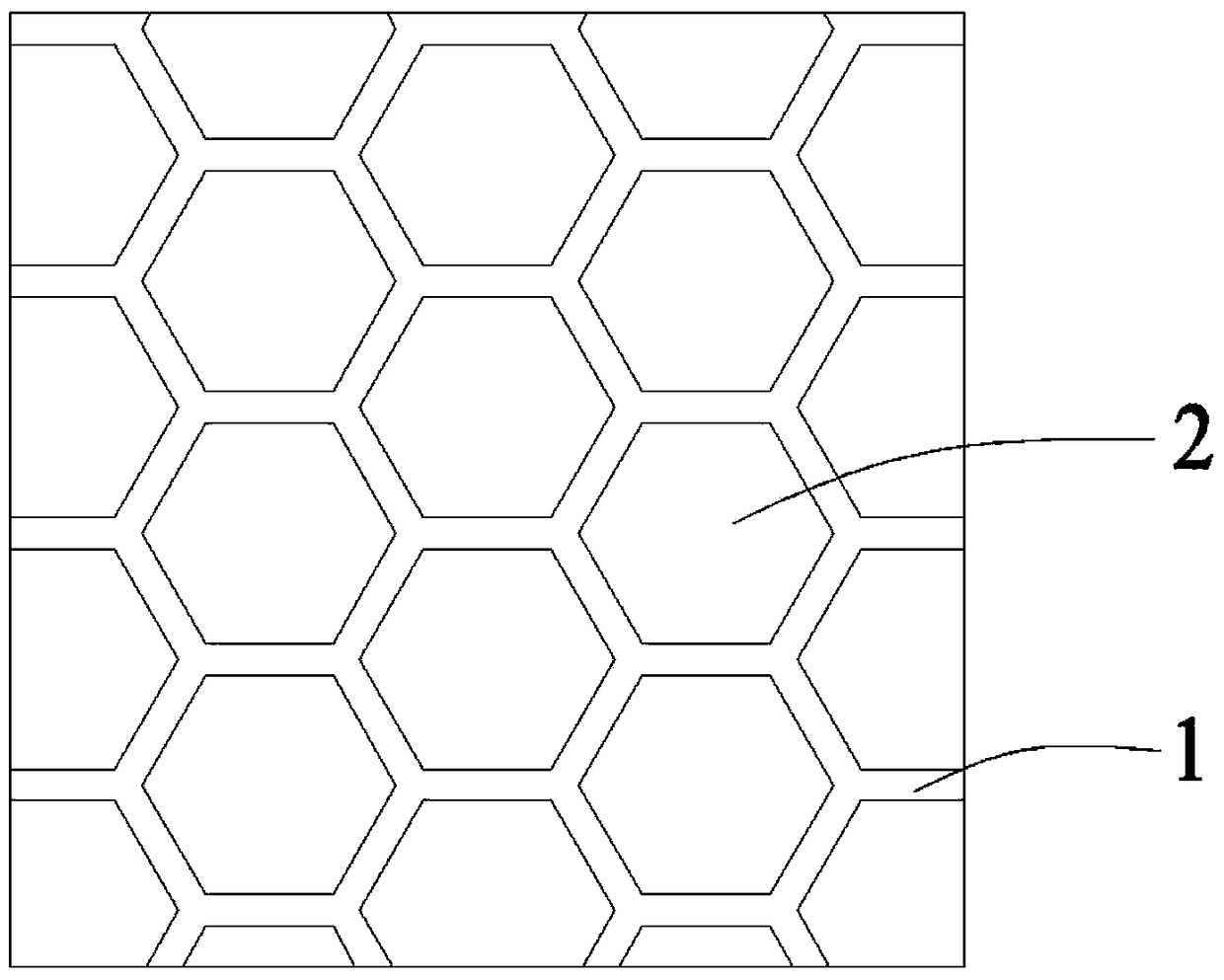

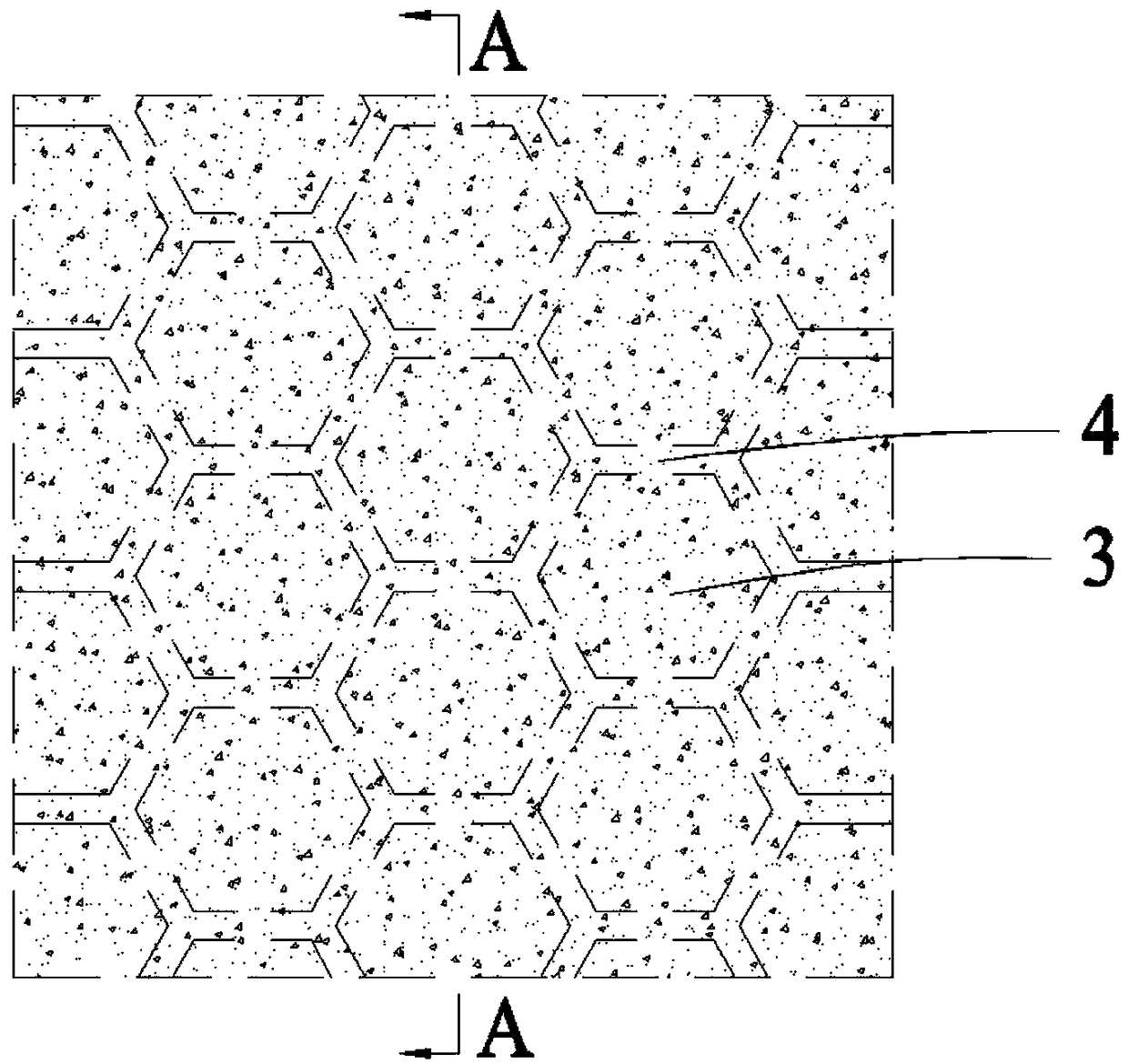

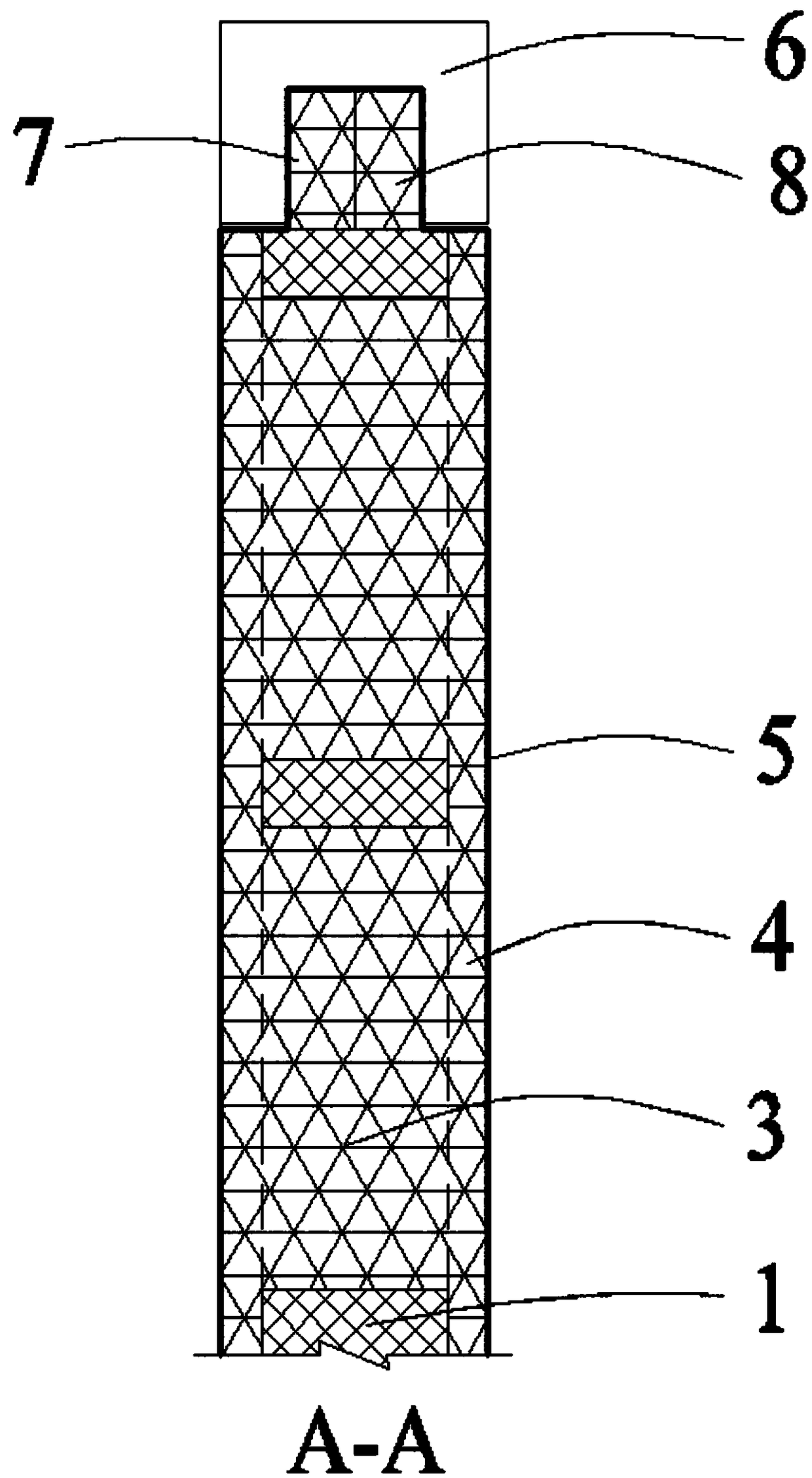

[0035] This embodiment is described by taking a concrete joint to be poured as an example. The width of the joint is 20 mm, and a formwork needs to be placed at the joint position during pouring. The template of this embodiment includes a sheet-like skeleton 1, such as figure 1 with 2 As shown, the skeleton 1 is a sheet structure made of PVC material. There are a plurality of through holes 2 evenly distributed on the skeleton 1. The wall thickness of the through holes 2 is 5 mm. The through holes 2 of this embodiment are regular hexagonal structures. The side length of the hole 2 is 20 mm, and the whole skeleton 1 has a honeycomb structure. The thickness of the skeleton 1 is 14mm.

[0036] The through hole 2 is filled with a first filling structure 3 that can expand after absorbing water, such as figure 2 with 3 As shown, the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com