Sliding type folding wallboard

A technology of pull-out and wall panels, which is applied in the direction of construction and building construction, can solve the problems of heavy construction and demolition workload, long time-consuming, high labor costs, etc., and achieve the effect of reducing the workload of demolition and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

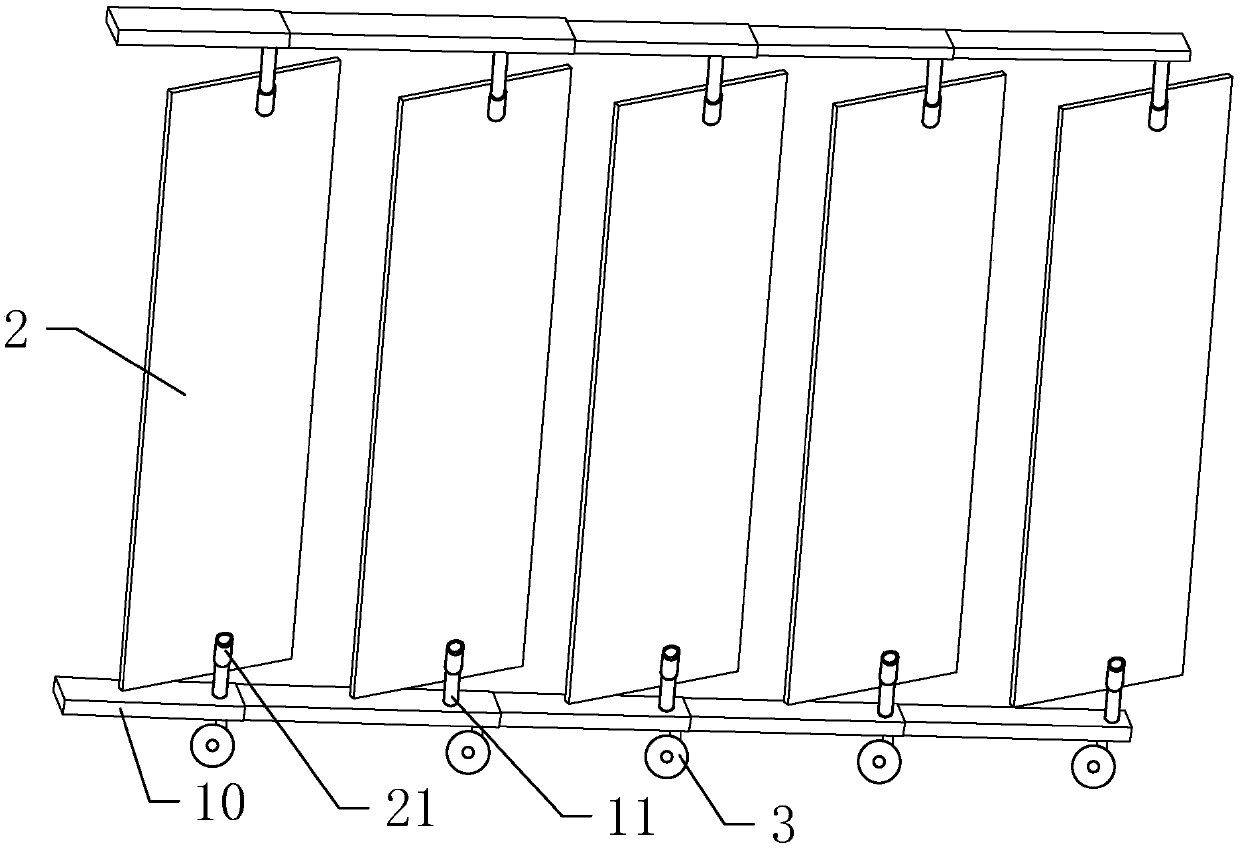

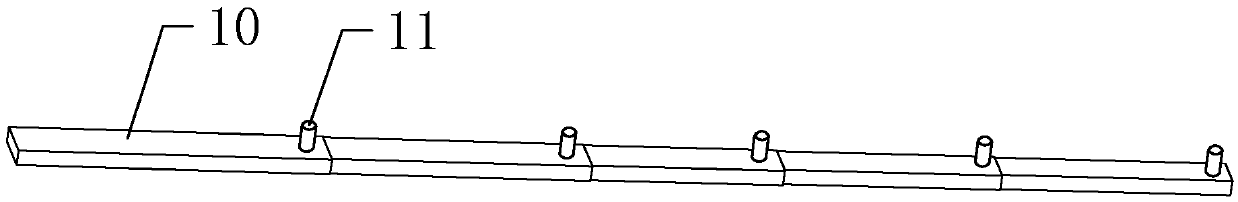

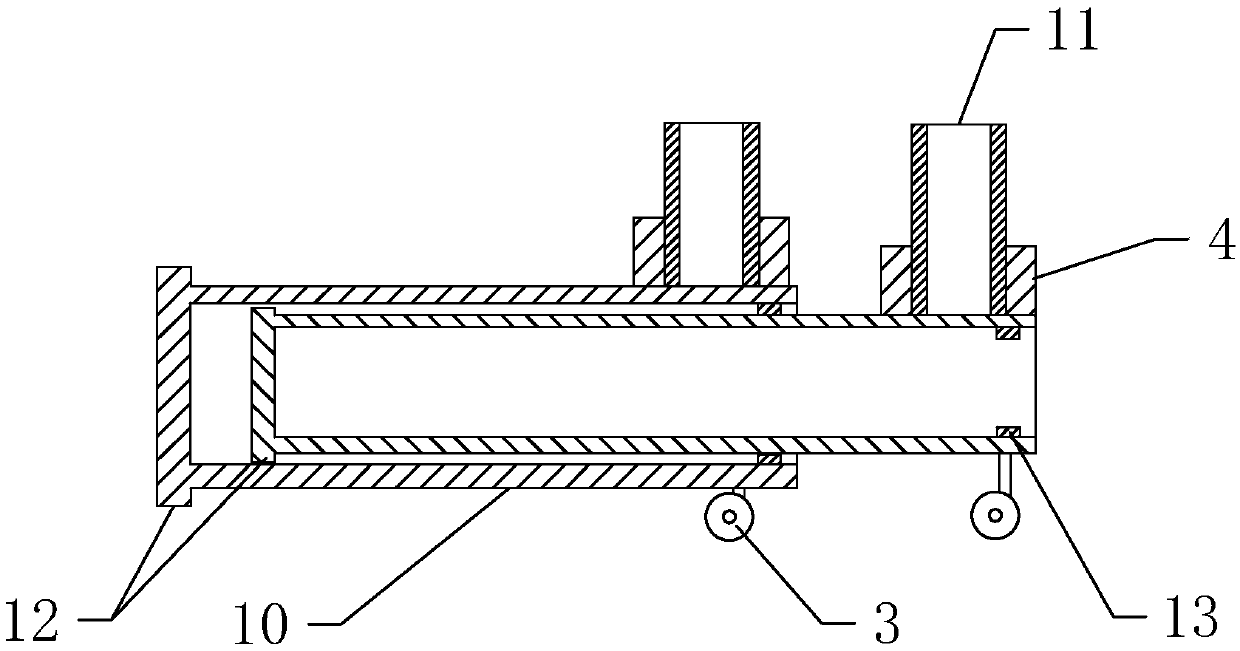

[0022] refer to Figure 1 to Figure 6 , which is Embodiment 1 of the present invention, specifically:

[0023] A pull-out folding wall panel, comprising a pull-out guide rail and at least two vertically arranged unit panels 2, the draw-out guide rail includes at least two hollow connecting pipes 10 set in sequence, the hollow connecting pipes 10 are arranged horizontally, The head of the hollow connecting pipe 10 is arranged in the afterbody of the adjacent hollow connecting pipe 10, and the afterbody of the hollow connecting pipe 10 is provided with a connecting shaft 11 arranged vertically, and the unit plate 2 corresponds to the connecting shaft 11 one by one, and the unit plate 2 is rotatably connected with the connecting shaft 11.

[0024] The structure of the present invention includes a folded state and an unfolded state. In the folded state, move the hollow connecting pipe 10 so that the tails of the hollow connecting pipe 10 are close to each other, the pull-out gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com