Tool type scaffold for elevator well

A tool-type, scaffolding technology, which is applied in the direction of scaffolding for house structure support, house structure support, house structure support, etc., can solve the problems of deformation affecting safety, labor input, and high material cost, so as to reduce construction costs, reduce erection and The effect of demolition workload and turnover frame material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

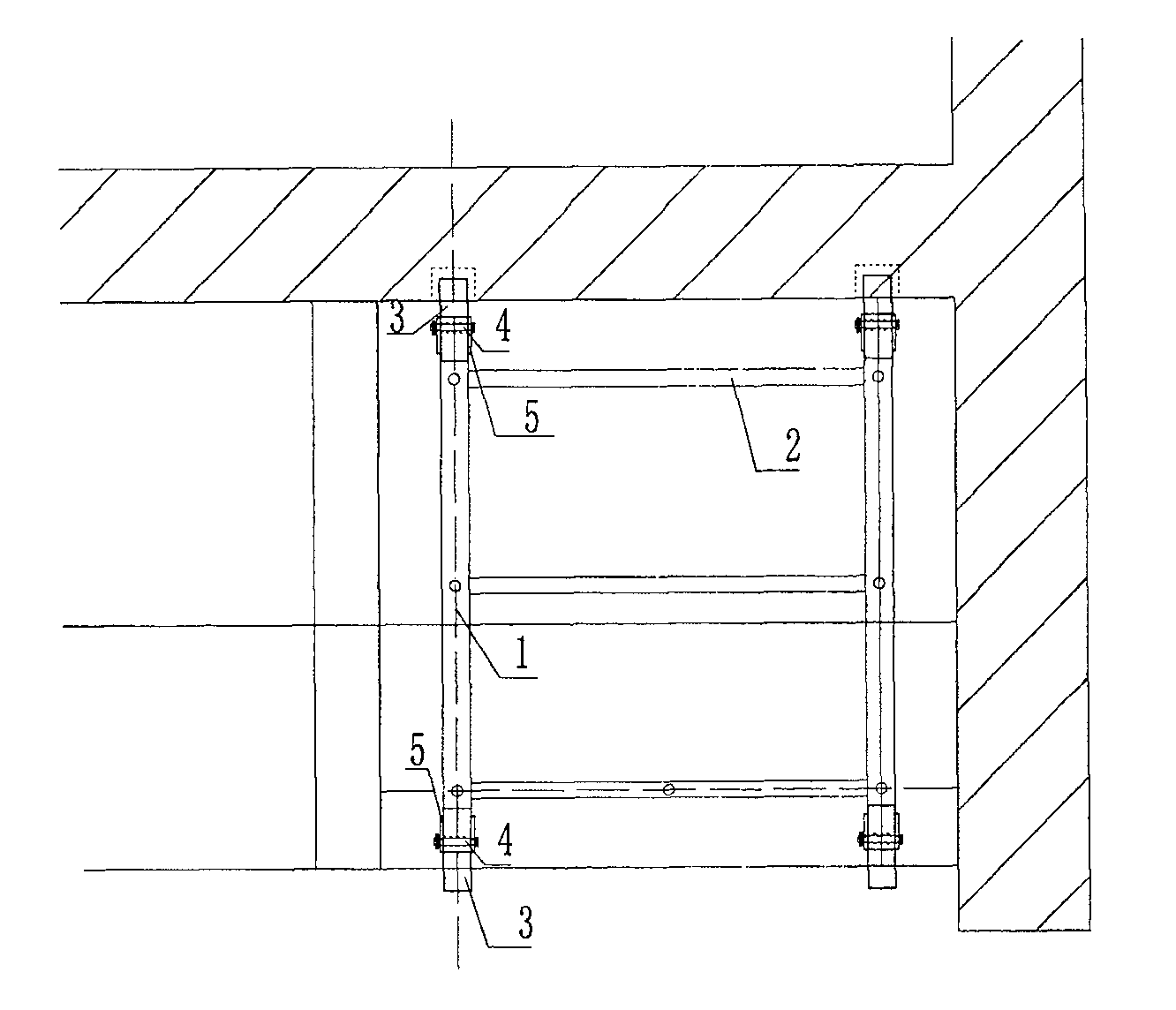

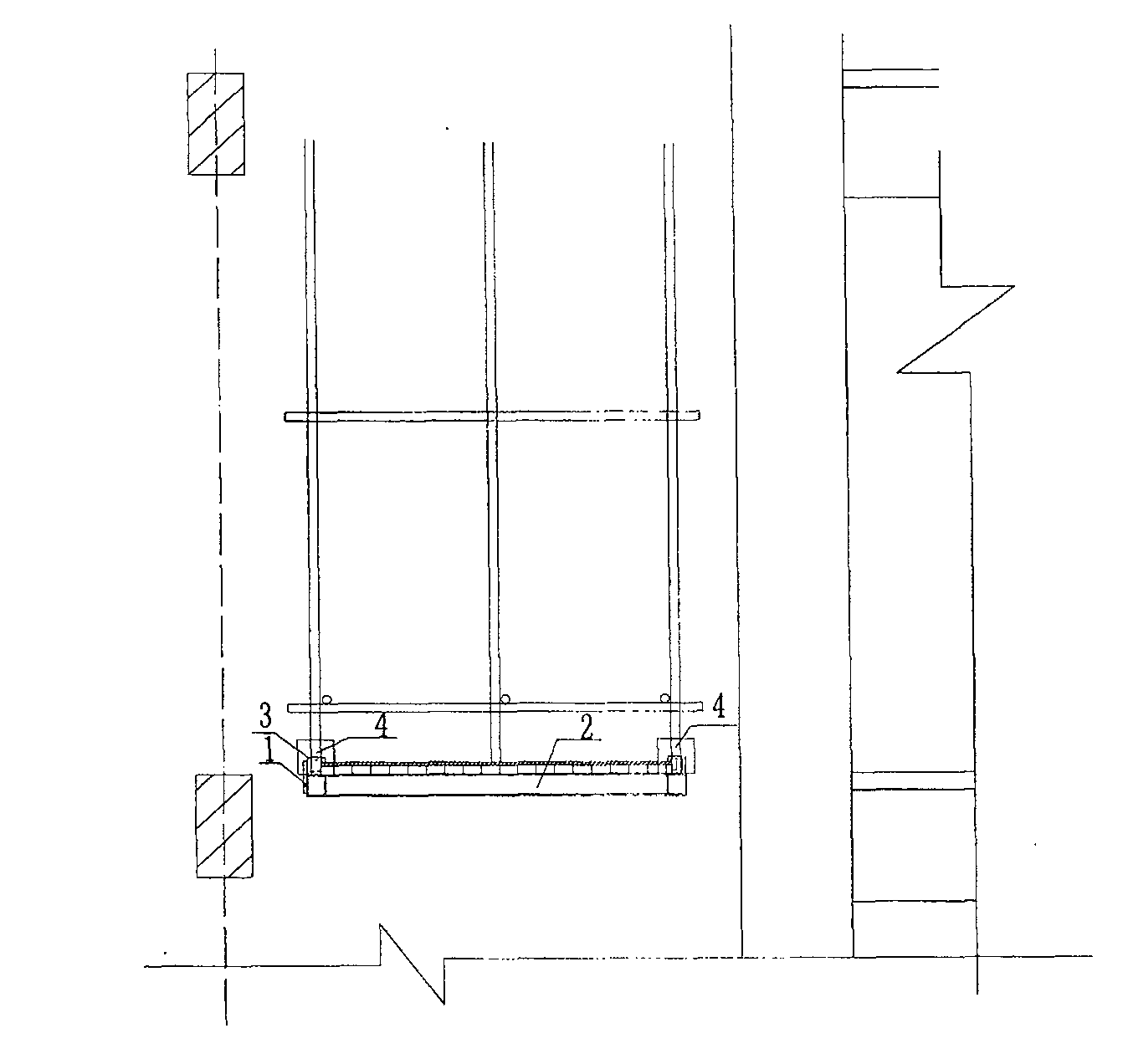

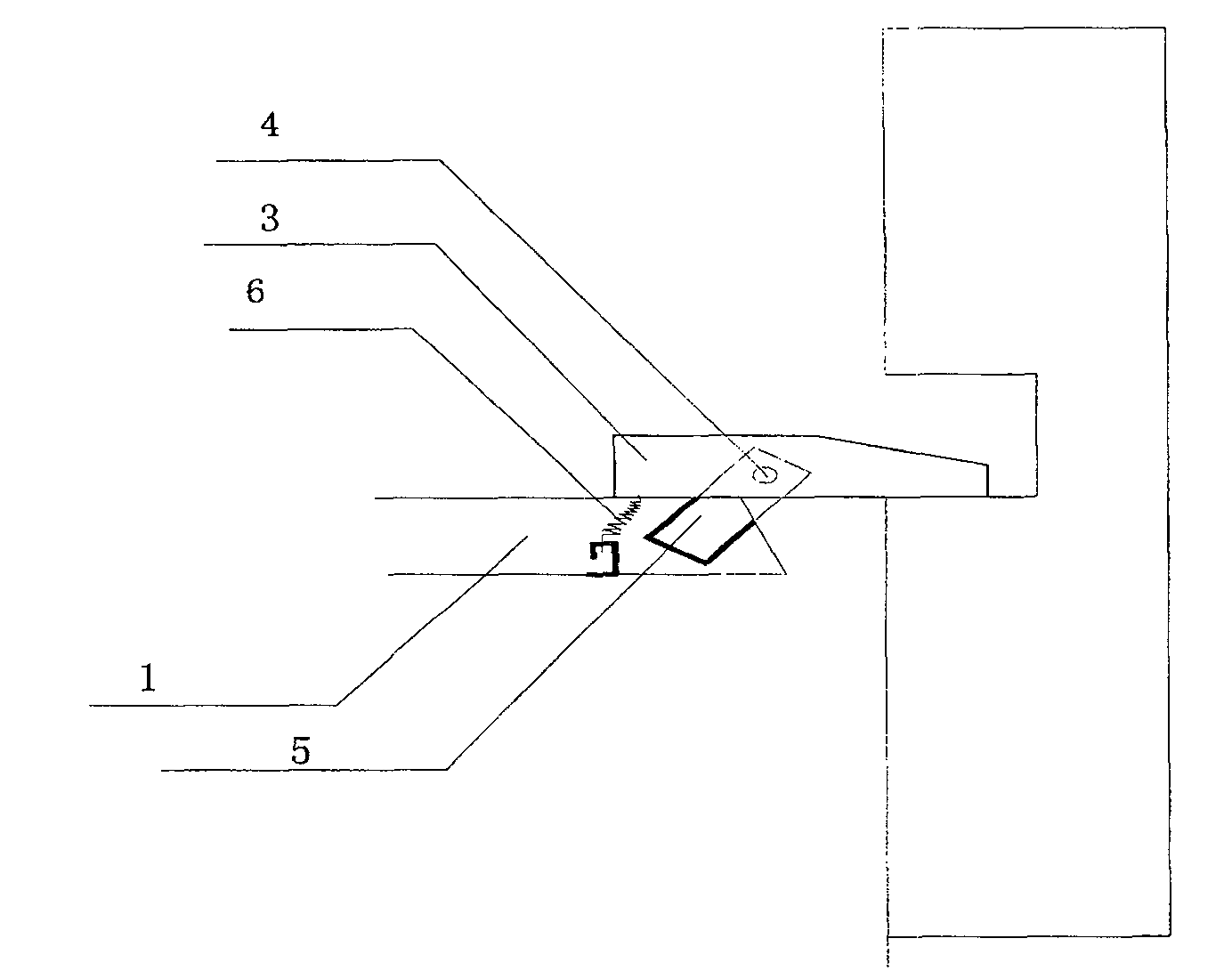

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown:

[0015] A tool-type scaffolding for an elevator shaft, comprising a main beam 1, an I-shaped steel beam 2, a crab claw 3, a pin shaft 4, a crab claw support 5, and a spring 6; the main beam 1 and the I-shaped steel beam 2 form an elevator shaft In the chassis of the tool-type scaffolding, the two ends of the main beam 1 are welded with crab claw supports 5, which are connected with the crab claws 3.

[0016] The crab claw support 5 is connected with the crab claw 3 through the pin shaft 4

[0017] The crab claw 3 can rotate around the pin shaft 4 .

[0018] The crab claw 3 is connected to the main beam 1 through a spring 6 .

[0019] The crab claw 3 is in a horizontal state in a fixed state. The spring 6 is in a relaxed state in a fixed state. The upper end of the spring 6 is connected with the crab claw 3, and the lower part is connected with the main beam 1. The crab claw 3 rotates outwards around th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com