Support-free construction method of steel-concrete concrete composite beam concrete cast-in-place bridge deck

A technology of steel-concrete composite beams and construction methods, which is applied to bridges, bridge parts, bridge materials, etc., and can solve problems such as high safety risks, high costs, and increased demolition workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

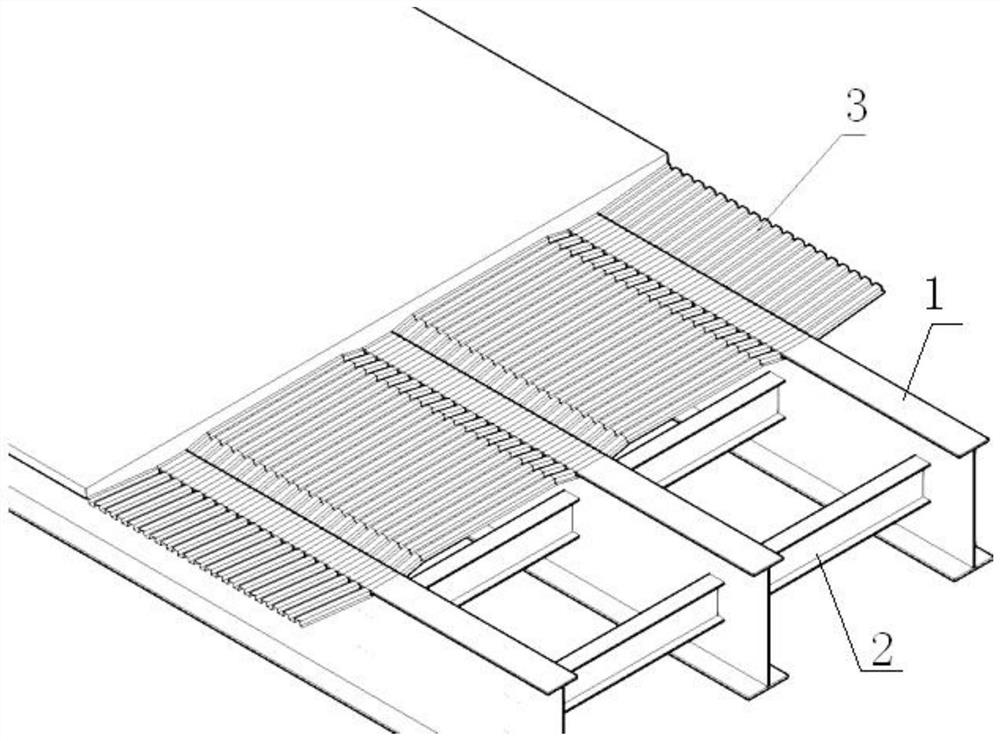

[0036] Such as Figure 1-3 As shown, a steel-concrete composite beam concrete cast-in-place bridge deck construction method without supports, including the following steps:

[0037] 1) Install steel girder 1 and steel beam 2 according to the requirements of the drawings, and process the required profiled steel plate 3 according to the horizontal line shape of the bottom surface of the bridge deck;

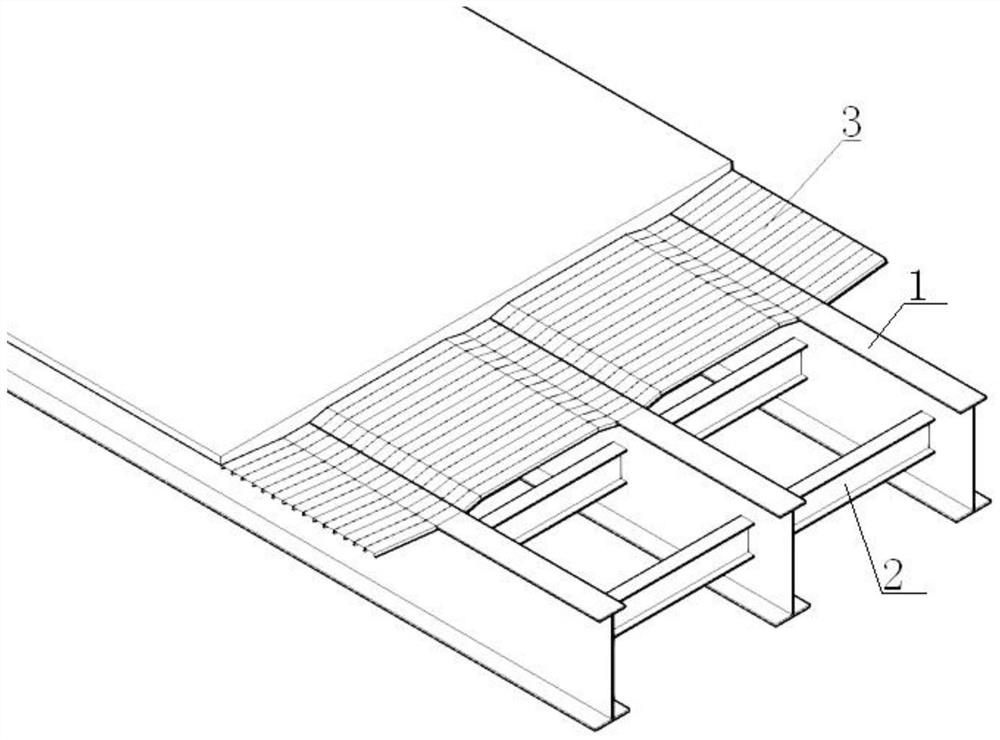

[0038] 2) Lay the processed profiled steel plates 3 section by section on the upper flange plate of the steel girder 1 along the direction of the bridge; the profiled steel plates 3 of each section are connected by lap joints, undercut connections, or snap connections;

[0039] 3) install the steel bars in the bridge deck on the profiled steel plate 3 laid in step 2);

[0040] 4) Install side forms on both sides of the bridge deck;

[0041] 5) Concrete is poured on the top of the profiled steel plate 3 in step 2) and inside the side form in step 3) and maintained.

[0042] The p...

Embodiment 2

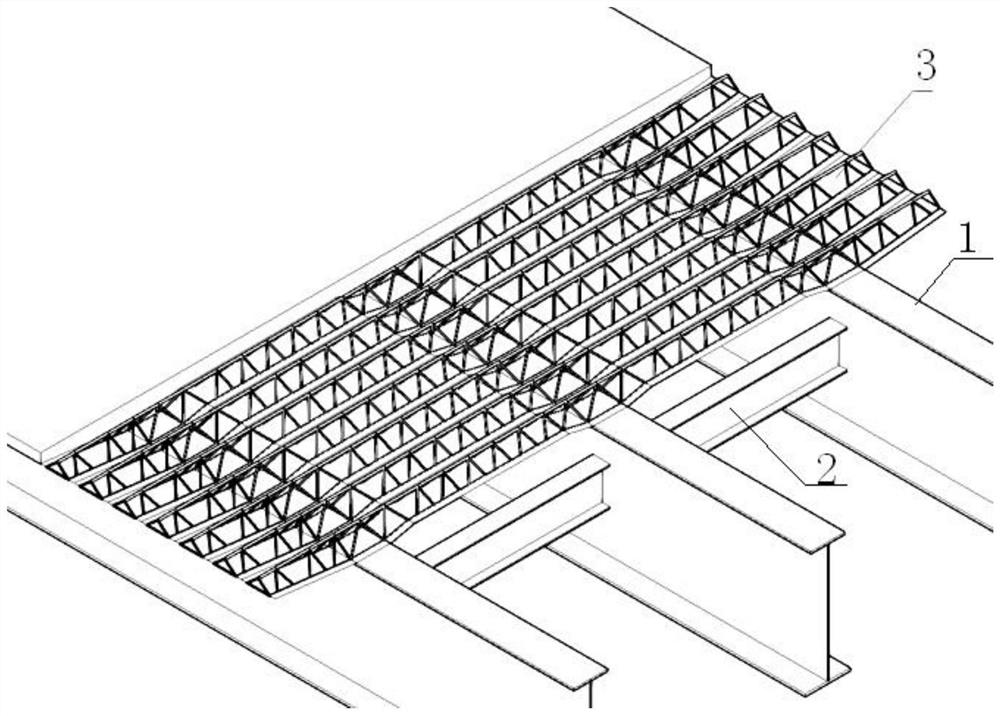

[0044] On the basis of Example 1, the profiled steel plate 3 includes an open profiled steel plate, a closed profiled steel plate, and a combined profiled steel plate. The combined profiled steel plate includes a bottom plate 4 and a steel bar truss 5, and the bottom plate 4 The steel bar truss 5 is connected to the top, and the bottom plate 4 is one of an open profiled steel plate, a closed profiled steel plate or a thin steel plate. The bottom plate 4 and the steel truss 5 are connected by threaded tie rods, bolts or welding;

[0045] When the profiled steel plate 3 is an open profiled steel plate, the open profiled steel plate is used as the bottom mold and load-bearing structure of the concrete bridge deck to realize construction without support; the open profiled steel plate is made of stainless steel plate or painted to meet the specification requirements The surface-coated steel plate realizes the construction without dismantling the bottom formwork; compared with the c...

Embodiment 3

[0047] On the basis of embodiment 2, when the profiled steel plate 3 is a closed profiled steel plate, the closed profiled steel plate is used as the bottom form and load-bearing structure of the concrete bridge deck to realize construction without support; the closed profiled steel plate uses The bottom surface of the bridge deck is flat, which is conducive to reducing the difficulty of demolition construction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com