Lifting platform for lifting large-span high-altitude corridor truss

A large-span and truss technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of high construction costs, achieve the effects of convenient erection and dismantling, reduction of total lifting weight, and convenient docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

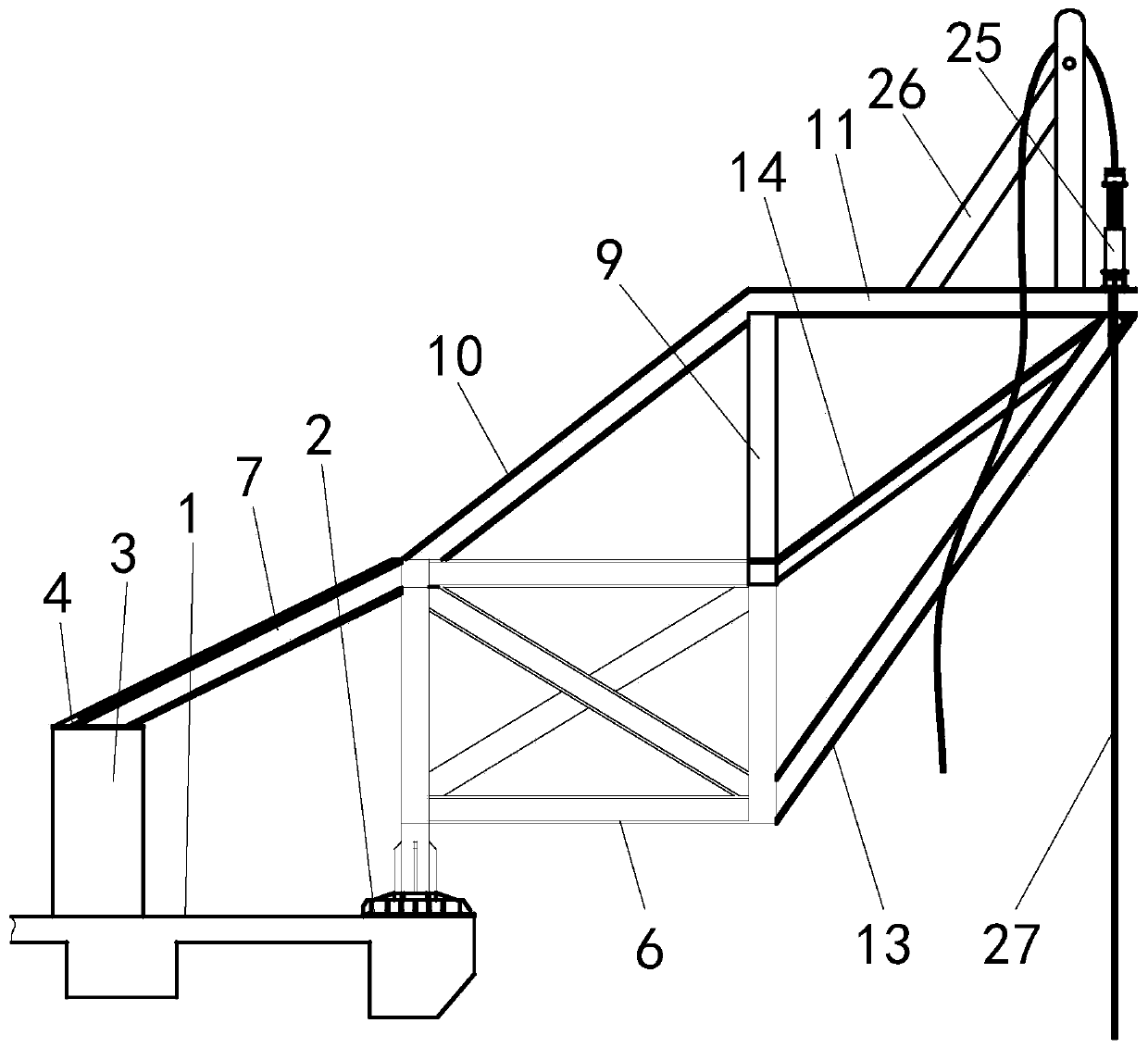

[0019] The following takes Nanjing Dingzheng Real Estate No.2011G38 plot project aerial corridor as an example. The underground height of this project is 13.75m, the ground height is 63.8m, and the total height is 77.55m. The height of the corridor truss is 2.3m, the span is 39m, the assembly elevation is -6.1m, and the lifting height is about 71m. If the existing technology is adopted, the estimated cost is about 750,000. After adopting the method of this example, the total cost is about 340,000 yuan, saving about 55% of the construction cost.

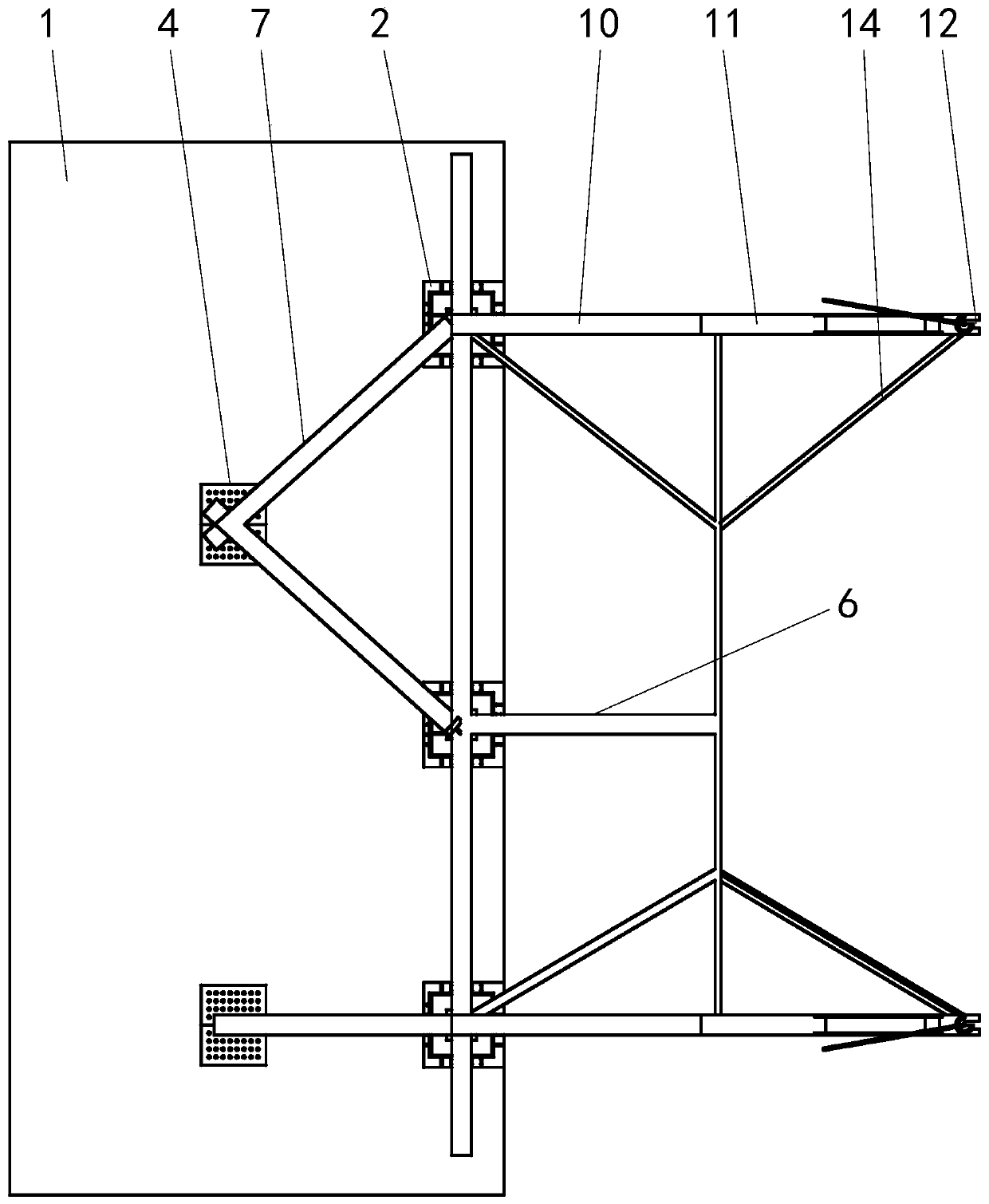

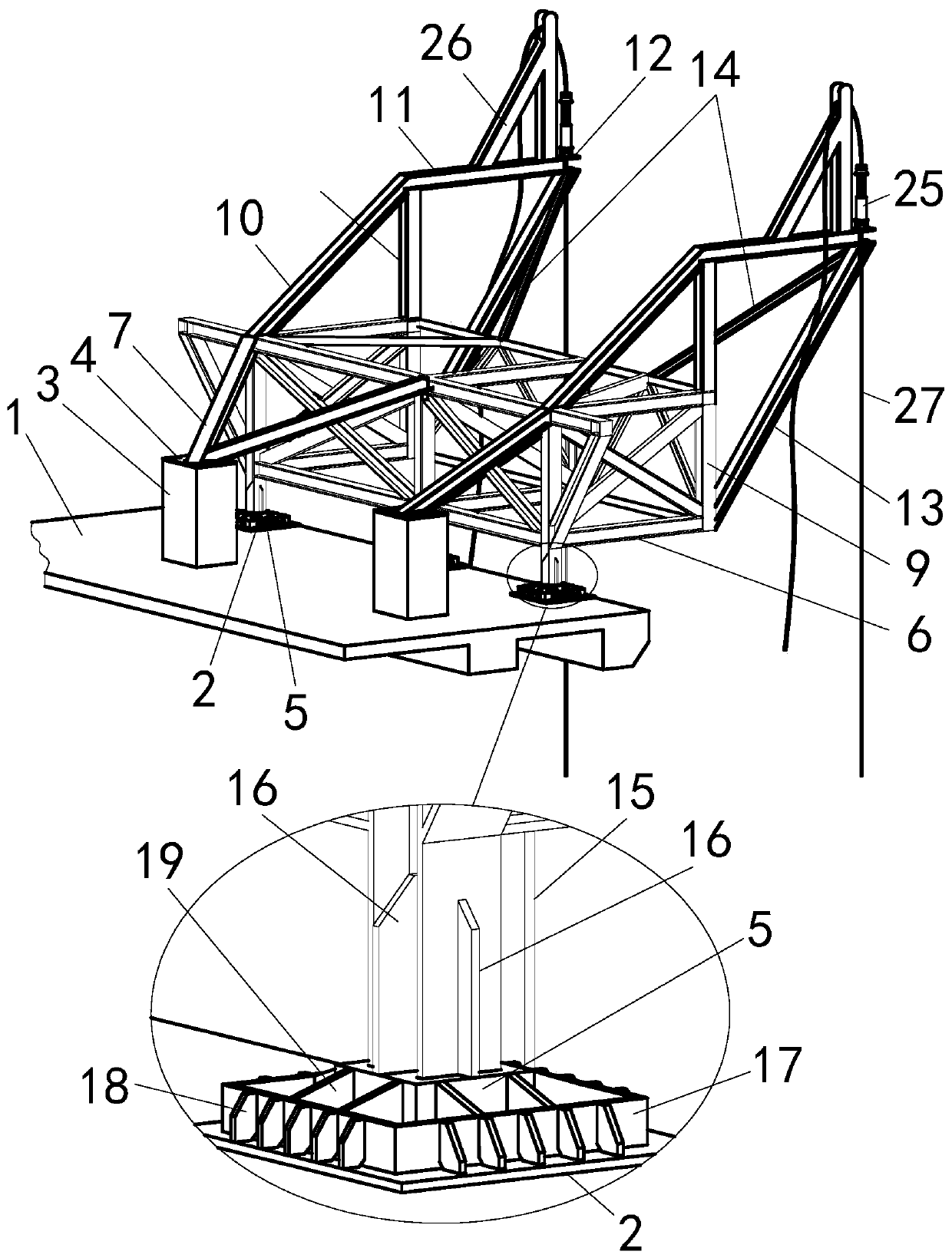

[0020] The method of this example is to divide the corridor truss into three sections, including a middle truss and two end trusses 6, and the two end trusses 6 can be directly assembled on the top surface 1 of the building as the basic support of the lifting platform. When assembling the end truss 6, the bottom of the foot 15 of the end truss 6 should be padded with a vibration-isolation support 5; The center of the top surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com