Water proofing and leak repairing construction method for sewage pipe network below underground water level

A sewage pipe network and groundwater level technology, applied in the sewer pipe system, waterway system, water supply device, etc., can solve the problems of no sewage pipe protection, waste of resources, high construction cost, etc., to achieve strong promotion and application value, save construction cost, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

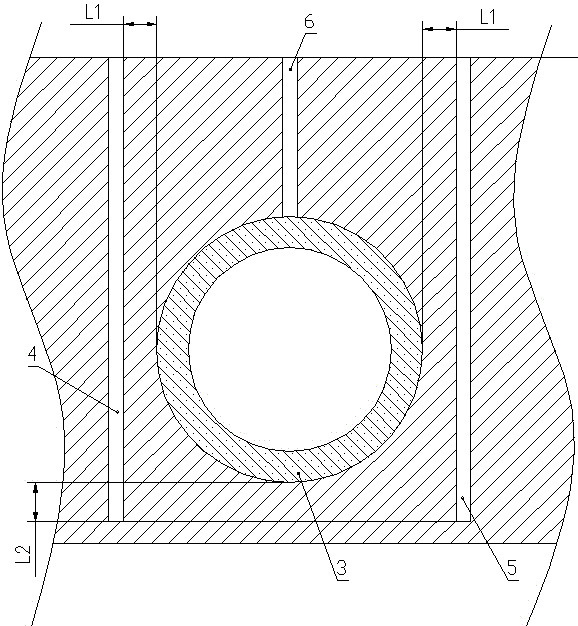

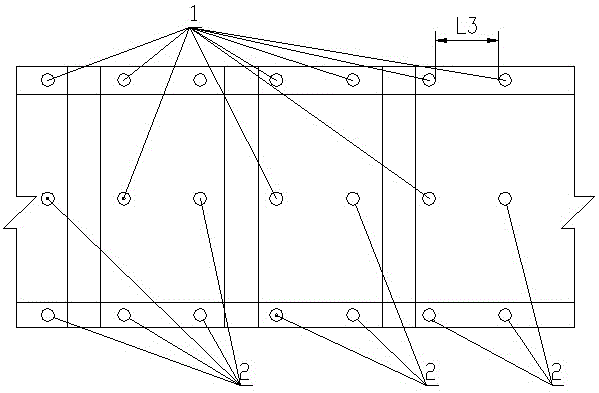

[0060] Such as figure 1 and figure 2 Shown, the sewage pipe network waterproof leakage repair construction method below groundwater level of the present invention carries out according to the following steps:

[0061] The first step is pipeline decontamination; the significance of pipeline decontamination is that on the one hand, only after decontamination can the leak point be accurately found, and on the other hand, it also creates construction conditions for leak repair.

[0062] The second step is to find and mark leaks;

[0063] The third step is to drill dewatering wells and carry out dewatering treatment on construction well points;

[0064] The fourth step is to plug the leak in the pipeline;

[0065] The fifth step is to drill the grouting hole and backfill the grouting with grout, that is, drill the grouting hole first, and then carry out the grouting backfilling grouting to the drilled grouting hole.

[0066] One, the first step, namely the pipeline cleaning st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com