Vertical shaft overall pouring section walling crib and vertical shaft overall pouring section walling crib construction method

A technology of integral pouring and construction method, which is applied in shaft equipment, earthwork drilling, wellbore lining, etc., and can solve problems such as small curtain radius, difficulty in the position of the final hole beyond the wild diameter range, poor grouting effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

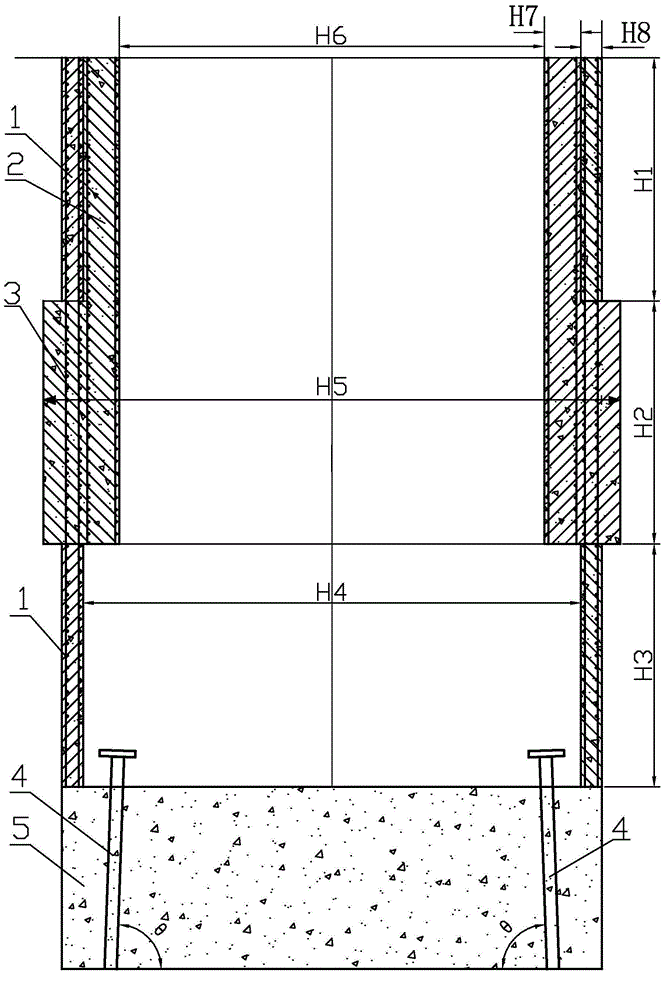

[0025] Specific implementation mode one: combine figure 1 To illustrate this embodiment, a vertical shaft integral casting section wall seat described in this embodiment includes a well outer wall 1, a well inner wall 2, a well wall seat 3, two water detection orifice pipes 4 and a grout stop pad 5, two water detection The orifice pipes 4 are respectively buried in the grout stop pad 5, the well wall seat 3 is connected with the outer wall of the well, the bottom end surface of the well wall seat is flush with the bottom end surface of the inner wall 2 of the well, the inner wall 2 of the well is connected with the outer wall 1 of the well, and the upper end surface of the inner wall 2 is It is flush with the upper surface of the outer wall of the well; the outer wall 1 of the well, the inner wall of the well 2 and the wall seat 3 of the well are made of concrete and steel bars.

[0026] The effect of this implementation mode:

[0027] The basic plan of this embodiment is to ...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment is different from Embodiment 1 in that: the height of the well outer wall 1 is the freezing depth of the shaft or the height of the designed casing wall section is designed according to the actual geological conditions; the inner diameter H4 of the well outer wall 1 is 6m ~12m; the wall thickness H8 of the well outer wall 1 is 0.35~0.6m. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0032] Specific embodiment three: this embodiment differs from specific embodiment one or two in that: the well inner wall 2 is the freezing depth of the well bore or the height of the designed casing wall section; the inner diameter of the well inner wall 2 (well shaft net diameter) H6 is 5m to 10m ; The wall thickness H7 of the well inner wall 2 is 0.5-1.0m. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com