Series mold bag retrusive type subsection slip casting device and slip casting method

A segmented grouting and retreating technology, which is applied in the fields of soil protection, construction, and infrastructure engineering, etc., can solve the problems of small reinforcement range, poor effect, and inability to directly segmental grouting, so as to ensure the grouting effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

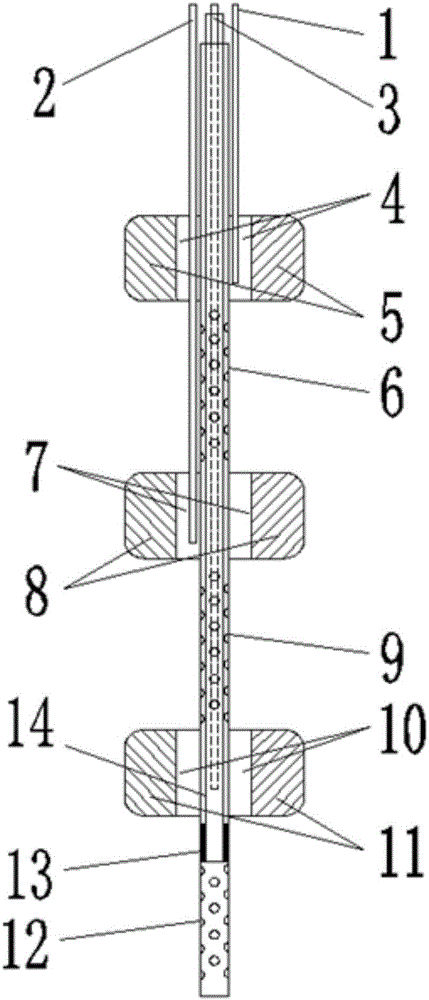

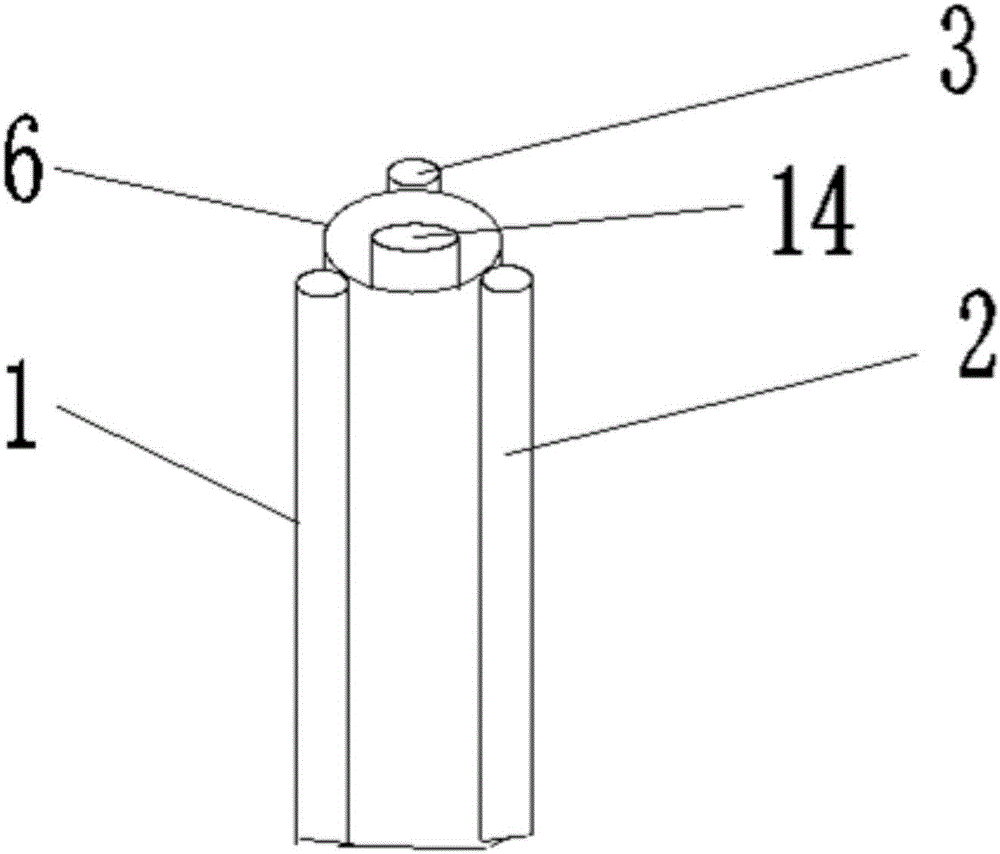

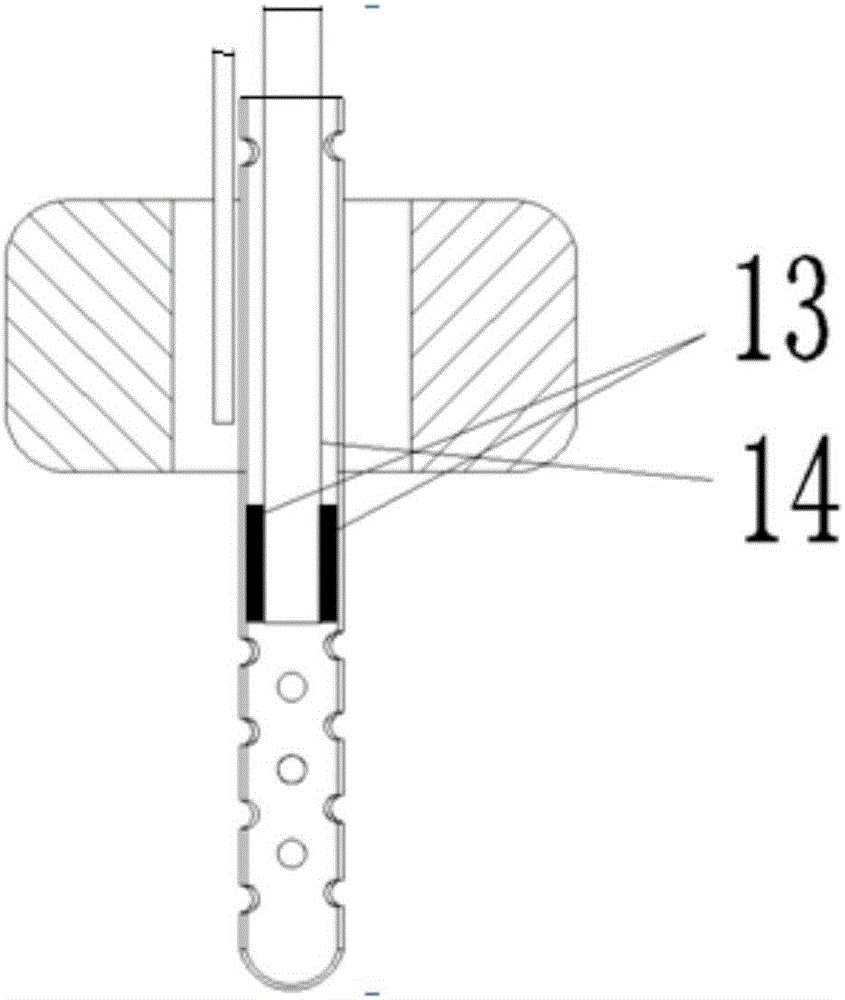

[0024] The device disclosed by the present invention includes a series of film bag retreat segmental grouting devices, which include a galvanized steel casing, and a plurality of mold bag grouting steel pipes of different lengths are arranged on the outer ring of the galvanized steel casing. The axis of the bag grouted steel pipe is parallel to the axis of the galvanized steel casing, and the end of each mold bag grouted steel pipe corresponds to a mold bag, and the end of each mold bag grouted steel pipe extends into the corresponding mold bag , realize the stretching of the mold bag, the stratum is squeezed during the mold bag stretching process, and a protective shell is formed; at the same time, the middle and lower mold bags are prevented from being too large on the ground surface during the stretching process; a plurality of the mold bags are set i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com