Geopolymer composite grouting material, and preparation method and use method thereof

A composite grouting and geopolymer technology, applied in the field of grouting materials, can solve the problems of high cost of grouting materials, slow release of potential activity, and limited compressive strength, etc., to achieve enhanced grouting effect, stable strength growth, Effects with little cost impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Put 7kg of cement clinker, 20kg of blast furnace slag, 17kg of metal mine tailings and 4kg of quicklime into a ball mill for grinding for 30 minutes, then put 10kg of metakaolin and 35kg of fly ash into the ball mill and continue grinding until the fineness reaches 45μm square hole sieve The balance is not more than 30%, and finally add 5kg of silica fume, 1.2kg of water reducer and 0.9kg of dispersible latex powder and mix well.

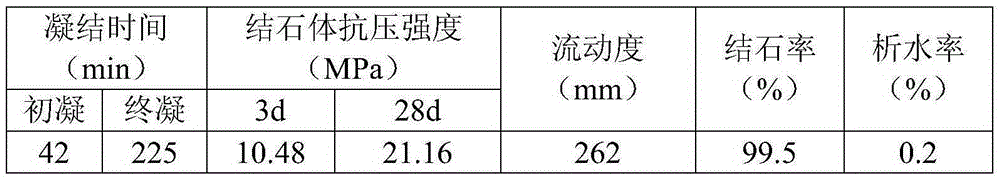

[0039] Mix the grouting material prepared by the above method with water at a weight ratio of 1:0.65 (that is, the water-cement ratio is 0.65), and its properties are as follows:

[0040]

Embodiment 2

[0042] Put 5kg of cement clinker, 15kg of blast furnace slag, 20kg of metal mine tailings and 6kg of quicklime into a ball mill for grinding for 30 minutes, then put 12kg of metakaolin and 42kg of fly ash into the ball mill to continue grinding until the fineness reaches 45μm square hole sieve The balance is not more than 30%, and finally add 3kg of silica fume, 1.0kg of water reducer and 0.6kg of dispersible latex powder and mix well.

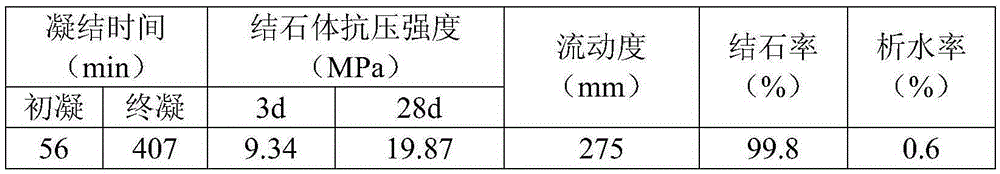

[0043] Mix the grouting material prepared by the above method with water at a weight ratio of 1:0.65 (that is, the water-cement ratio is 0.65), and its properties are as follows:

[0044]

Embodiment 3

[0046] Put 6kg of cement clinker, 17kg of blast furnace slag, 18kg of metal mine tailings and 5kg of quicklime into a ball mill for grinding for 30 minutes, then put 11kg of metakaolin and 40kg of fly ash into the ball mill and continue grinding until the fineness reaches 45μm square hole sieve The balance is not more than 30%, and finally add 4kg of silica fume, 1.1kg of water reducing agent and 0.7kg of dispersible latex powder and mix well.

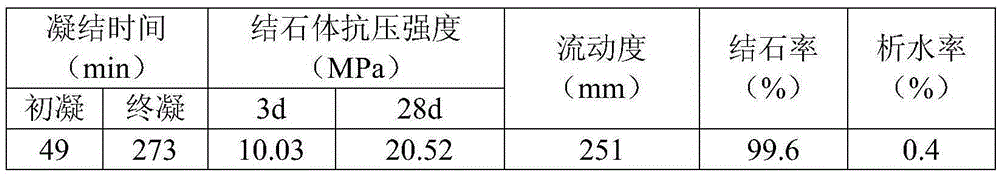

[0047] Mix the grouting material prepared by the above method with water at a weight ratio of 1:0.65 (that is, the water-cement ratio is 0.65), and its properties are as follows:

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com