Roadbed subsidence grouting treatment structure and construction method thereof

A technology for controlling structure and roadbed, applied in the field of roadbed subsidence grouting treatment structure and construction, can solve the problems of roadbed subsidence, affecting roadbed stability, water can not be discharged in time, etc., achieving simple construction technology, ensuring grouting effect, and ensuring roadbed strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

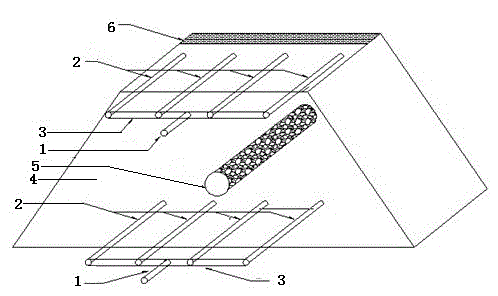

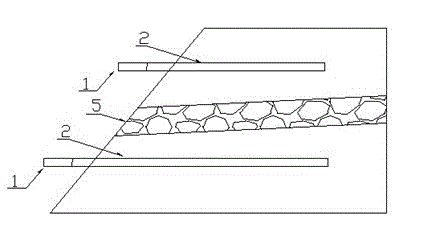

[0018] see figure 1 and figure 2 , the roadbed subsidence grouting treatment structure includes two rows of grouting pipes arranged on both sides of the central divider 6 and horizontally inserted into the roadbed 4 from the outside of the roadbed 4, each row of grouting pipes includes several grouting pipes 2, One end of several grouting pipes 2 in the same row exposed outside the subgrade 4 communicates with one side of the same connecting pipe 3, and the other side of the connecting pipe 3 communicates with the main grouting pipe 1; There is a drainage ditch 5 in the same direction as the grouting pipe 2.

[0019] Wherein, the drainage ditch 5 is filled with stones. The drainage ditch 5 is inclined from the central partition 6 to the outer edge of the roadbed 4 . The slope of the drainage ditch 5 is ≥2%, preferably 10%. The grouting pipe 2 is a grouting steel flower pipe; the grouting main pipe 1 and the connecting pipe 3 are both steel pipes. Each row of grouting pip...

Embodiment 2

[0021] The construction subgrade is 8m high, and the horizontal grouting is carried out vertically in two layers, that is, the horizontal flower tube grouting is carried out from the top surface of the subgrade 2m and 5m respectively, and four grouting tubes are arranged in each layer with a spacing of 3m. Four grouting pipes are led out of the side slope by a main grouting pipe to facilitate grouting. The length of the upper grouting pipe is 16.9m, and the length of the lower grouting pipe is 21.5m. Between the two layers of horizontal grouting flower tubes, a drainage seepage ditch is laid 3.5m away from the top surface of the subgrade. The cross section of the seepage ditch is circular with a diameter of 2m, filled with gravel, and slopes from the central separation zone to the outer edge of the slope with a slope of 10% to facilitate water discharge.

[0022] The construction method of the subsidence grouting treatment structure of the subgrade:

[0023] (1) Place remind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com