Filling and construction method for goaf below tunnel

A goaf and tunnel technology, which can be used in filling materials, earth-moving drilling, mining equipment, etc., can solve problems such as poor economy and environmental protection, and achieve the effect of good filling and compacting effect, good promotion and application value, and guarantee the overall strength.

Inactive Publication Date: 2014-01-08

中铁二十四局集团安徽工程有限公司 +1

View PDF3 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although this method can ensure the integrity of the surrounding rock to the greatest

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

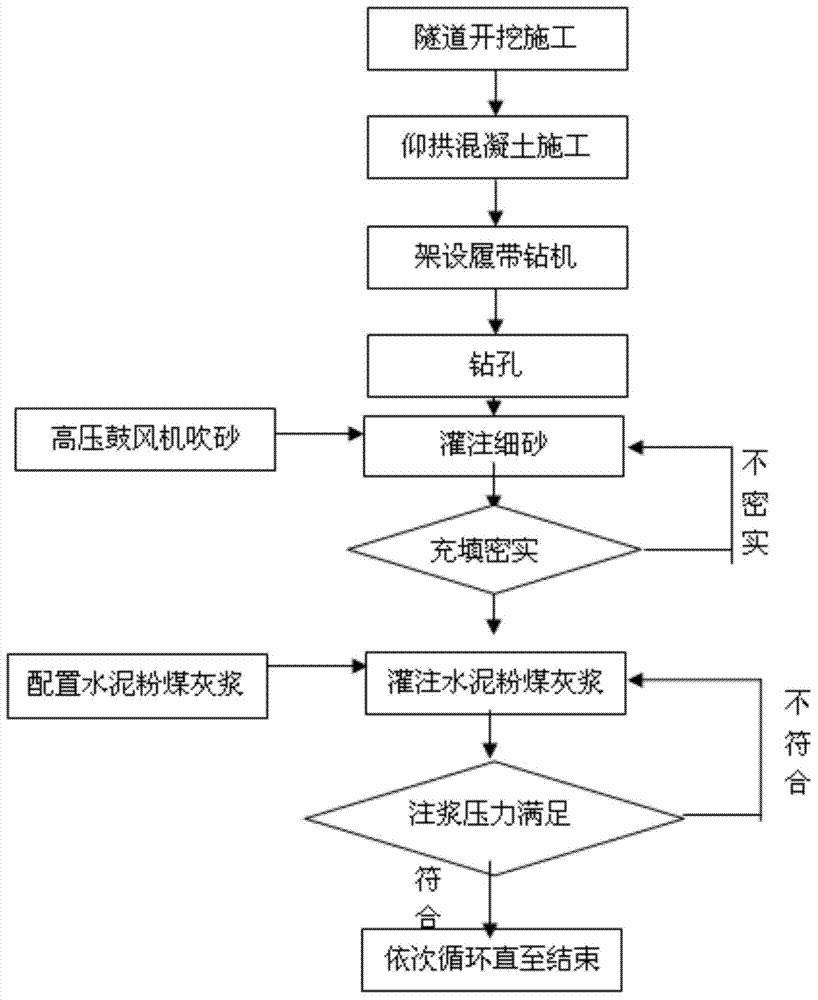

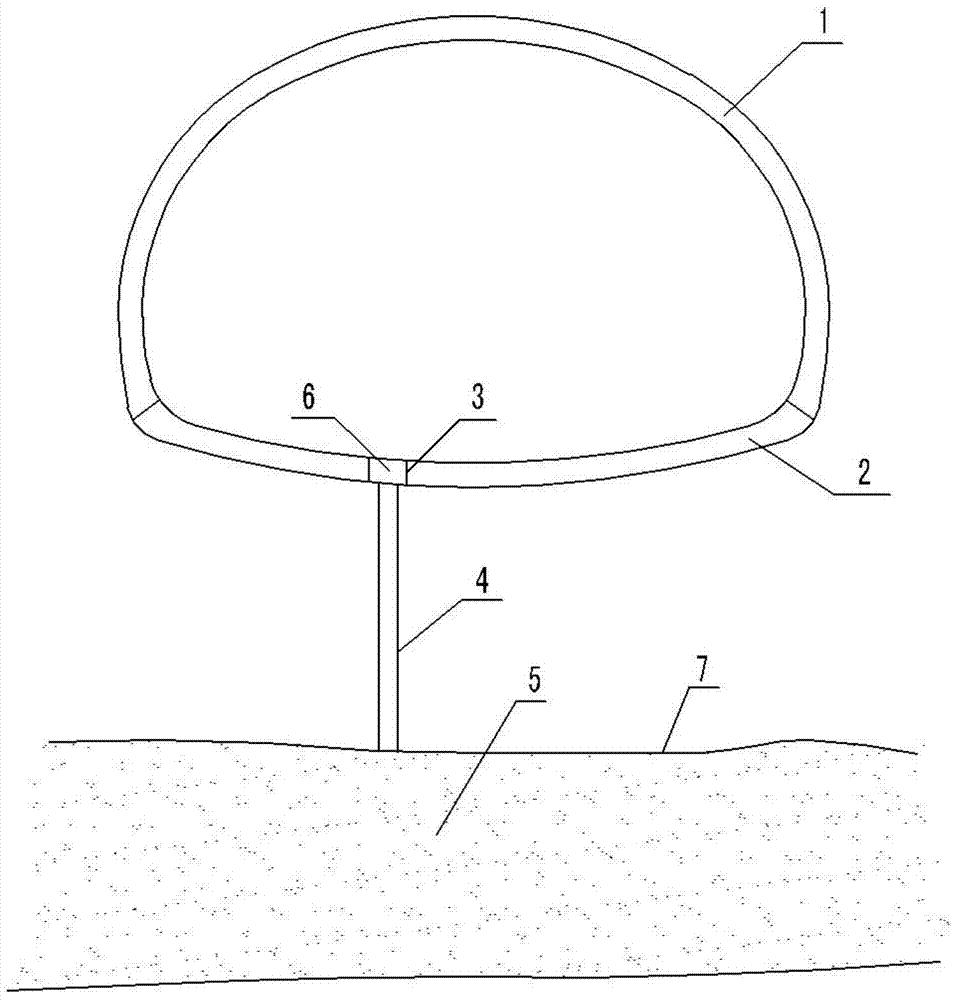

The invention discloses a filling and construction method for a goaf below a tunnel. The filling and construction method is characterized in that inverted arch construction is carried out on the tunnel which is already dug, inverted arch concrete is poured, inverted arch maintenance is achieved, and the sealed inverted arch in the tunnel is formed; a drill machine is used for drilling holes in the bottom of the tunnel in the inverted arch to form goaf grouting holes; fine sand is poured into the goaf below the tunnel through the goaf grouting holes until no hole exists in the goaf; cement powder coal ash is poured to the goaf below the tunnel through the goaf grouting holes, and the grouting pressure of the cement powder coal ash is controlled between 2.0MPa and 4.0MPa, and is maintained for 5-10 minutes; the concrete is adopted to seal the grouting holes, and goaf filling is completed. The filling and construction method can effectively improve the filling quality of the goaf, and has high economic benefits, social benefits, environment-friendly benefits and energy-saving benefits.

Description

technical field [0001] The invention relates to the technical field of tunnel construction, in particular to a construction method for filling goafs below tunnels, which is suitable for filling and compacting construction of coal seams and metal mine goafs under highways, urban roads, and railway tunnels, and can be popularized and applied to foundations in karst areas Reinforcement treatment. Background technique [0002] With the development of my country's national economy, the construction of railways and highways is increasing. Due to the lack of preliminary survey data or the need for geographical location, the tunnel may pass through the goaf, especially in some coal-rich areas in my country. Most of the mined-out areas of small coal kilns exist. If the mined-out area below the tunnel is not handled properly, especially for railways and expressways, where the load is heavy and the running speed is fast, the lining structure may be damaged after the tunnel is completed...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21F15/08

Inventor 韩俊王辅圣严来章鲁璐谈东亚

Owner 中铁二十四局集团安徽工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com