Fatigue crack reinforcing structure and method for arc-shaped notch of diaphragm plate of steel bridge deck

A steel bridge deck, fatigue crack technology, used in bridge reinforcement, bridges, bridge parts, etc., can solve the problems of secondary cracking at welds or bolt openings, the repair effect depends on construction quality, and the stability is difficult to guarantee. Avoid anchoring devices and heavy tensioning equipment, reduce construction difficulty and facilitate transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

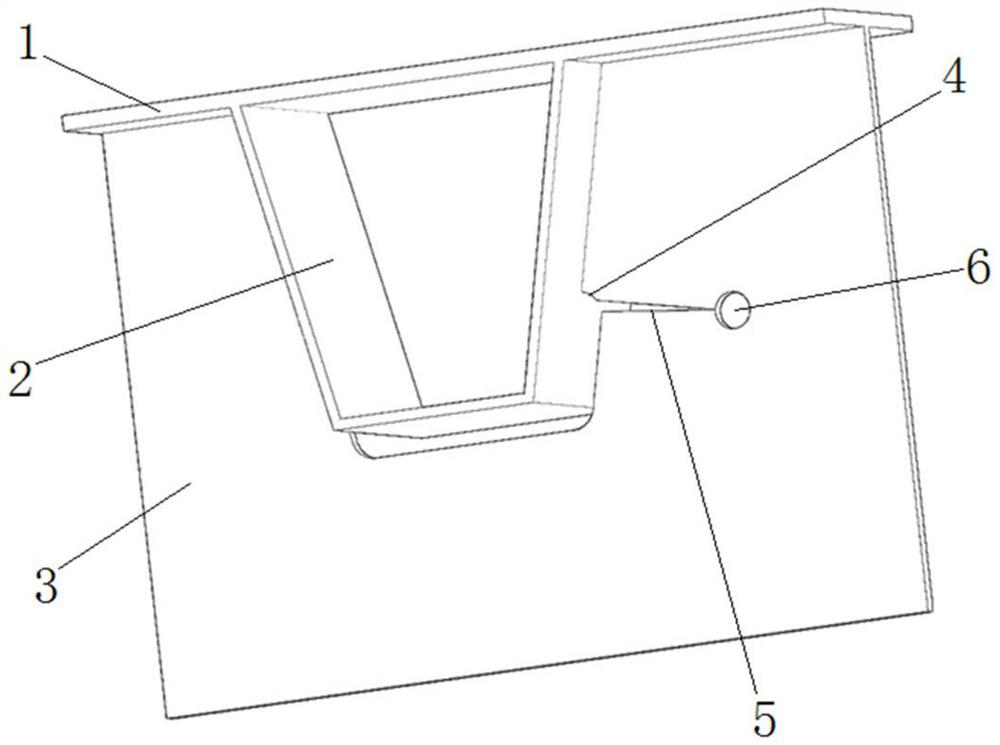

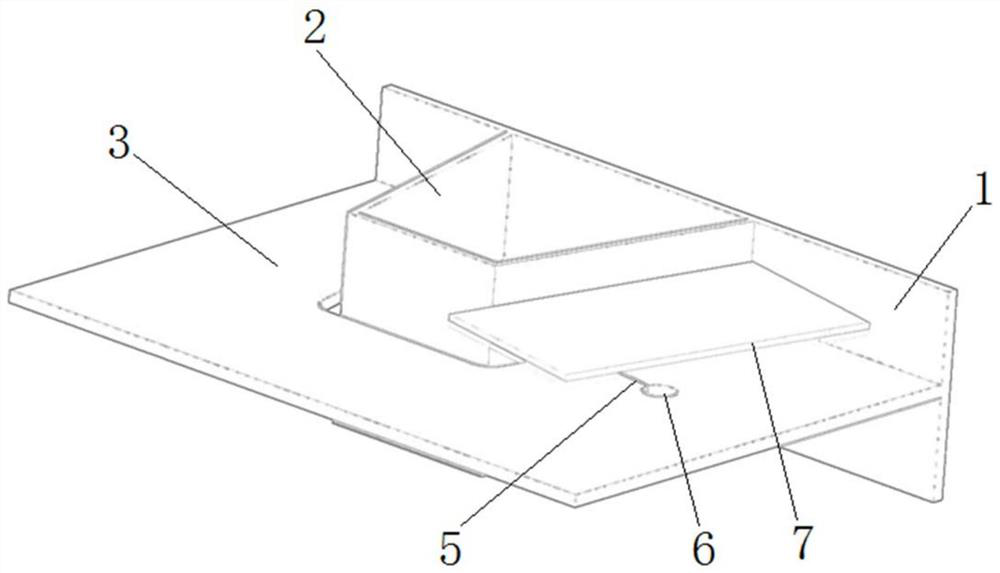

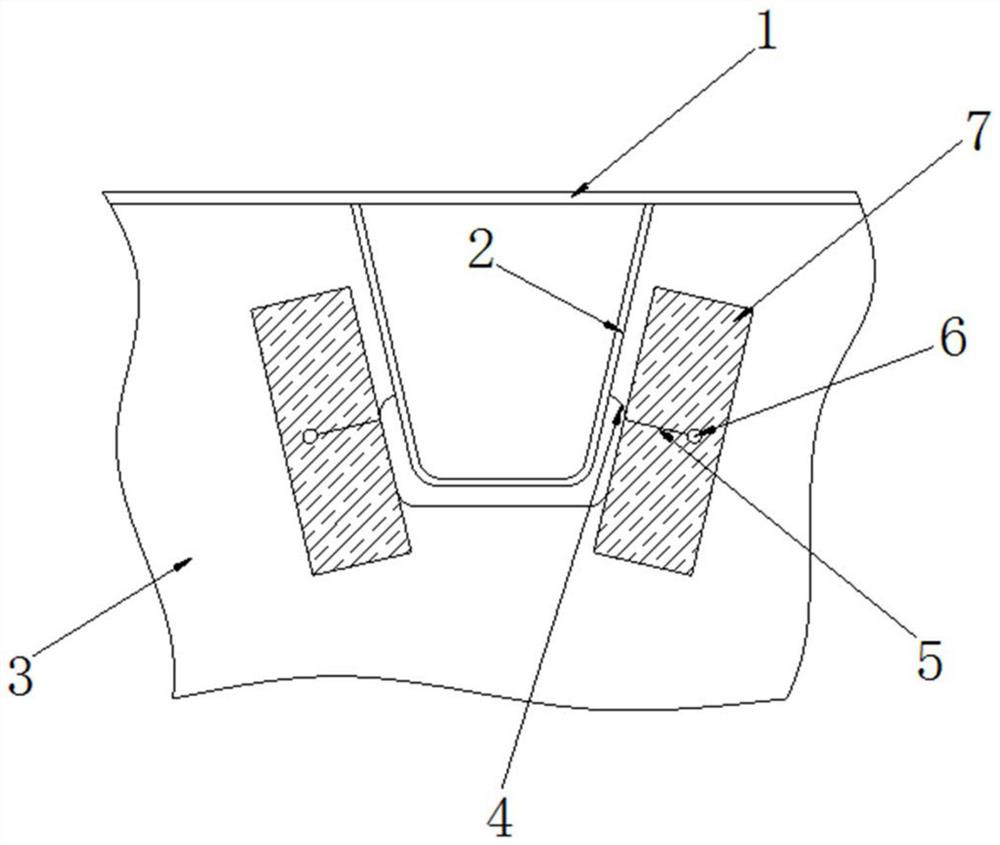

[0043] Such as figure 1 , figure 2 , image 3 As shown, the steel bridge deck includes a steel bridge deck top plate 1, a longitudinal U-rib 2 arranged at the bottom of the steel bridge deck top plate 1, and a plurality of diaphragms 3 arranged at intervals at the bottom of the steel bridge deck top plate 1, and the inner side of the transverse diaphragm 3 There are arc-shaped cutouts 4 matching the longitudinal U-ribs 2 , and fatigue cracks 5 are located on the diaphragm 3 .

[0044] A reinforcement structure for fatigue cracks at the arc-shaped cutout of the diaphragm of a steel bridge deck, including a crack stop hole 6 provided on the diaphragm 3, a shape memory alloy sheet 7 arranged on the side of the diaphragm 3, and the inner end of the fatigue crack 5 It is connected with the arc-shaped cutout 4 , and the outer end is connected with the crack arrest hole 6 , and the shape memory alloy sheet 7 covers the fatigue crack 5 and the crack arrest hole 6 at the same time. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com