Method for designing and constructing waterproof plate for underground garage by post-tensioning bonded prestressed construction process

A bonded prestressed, underground garage technology, applied in water conservancy projects, infrastructure engineering, artificial islands, etc., can solve the problems of undiscovered bonded prestressed underground garage waterproof board construction method, increased cost of turnover materials, and the impact of the owner's construction period and other problems, to achieve superior crack resistance, fast and convenient binding plate reinforcement, and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

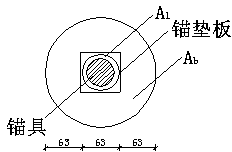

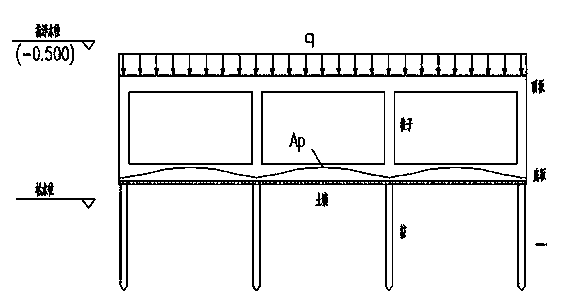

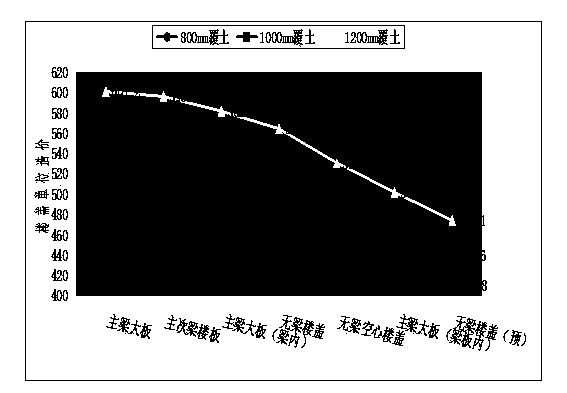

[0054] A design and construction method of a post-tensioned waterproof board for an underground garage with bonded prestress. The waterproof board of the underground garage adopts a beamless structure including a bottom plate and a roof, and post-tensioned construction with bonded prestress. The construction method mainly includes Reinforcing, pouring, tensioning, grouting and cutting and anchoring procedures, details are as follows:

[0055] In the reinforcement distributing process, the prestressed tendons run through the bottom of the pier cap of the underground garage floor column pier, and the prestressed tendons in the prestressed tendons cannot pass through two shear walls at the same time, and the tension of the floor prestressed tendons The end is set in the center of the base plate or in the area of the post-cast tape.

[0056] In the present invention, Fengze Yiyuan in Rugao, Jiangsu Engineering example:

[0057] The cross-sectional size and mechanical properti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com