Subsection retrusive slip-casting method for porthole slurry-stop mixed double-pipe within tube

It is a technology of in-pipe mixing and retreating, which is applied in earth square drilling, soil protection, wellbore lining, etc. It can solve problems such as pipe sticking, reduce construction technology, ensure pressure and grouting effect, and improve grouting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

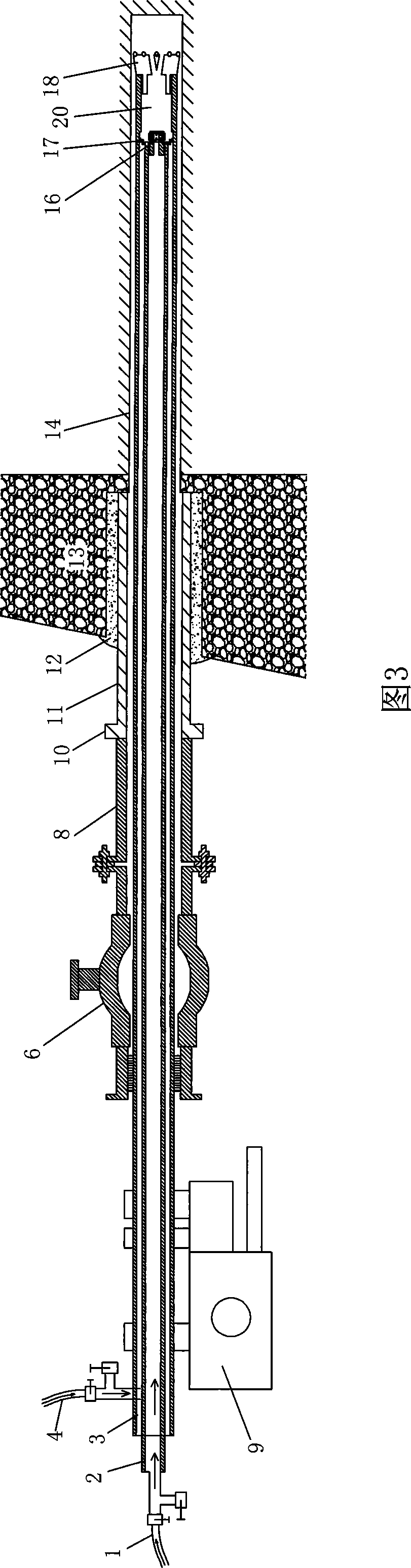

[0009] Embodiment of the present invention is described in conjunction with accompanying drawing:

[0010] The processing steps of the grouting method proposed by the present invention are:

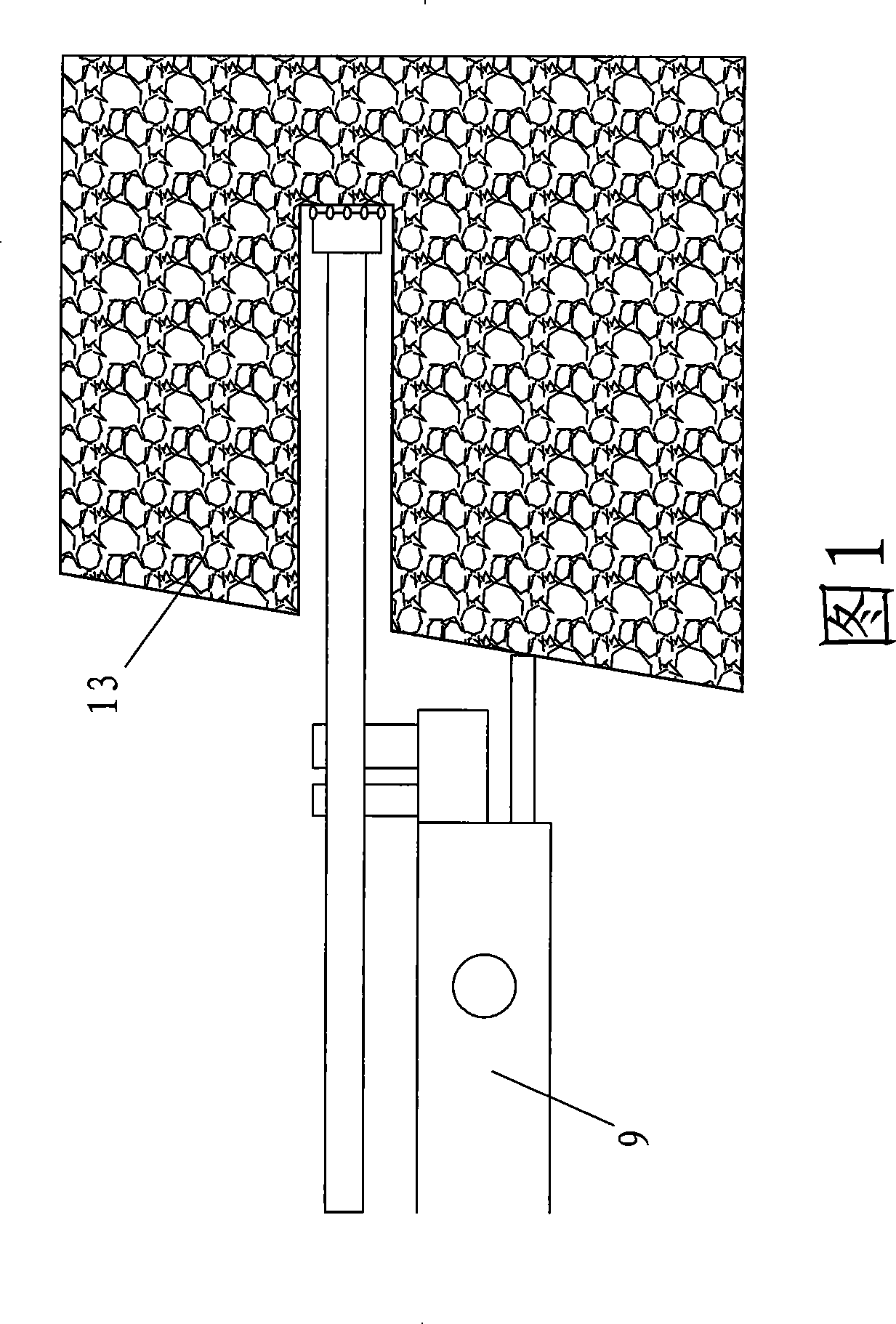

[0011] As shown in Figure 1, Step 1 Drill shallow holes. After the drilling machine 9 is in place, the angle of the drilling machine is adjusted according to the opening position and drilling parameters to meet the design drilling requirements, and the drilling length is 1.8m.

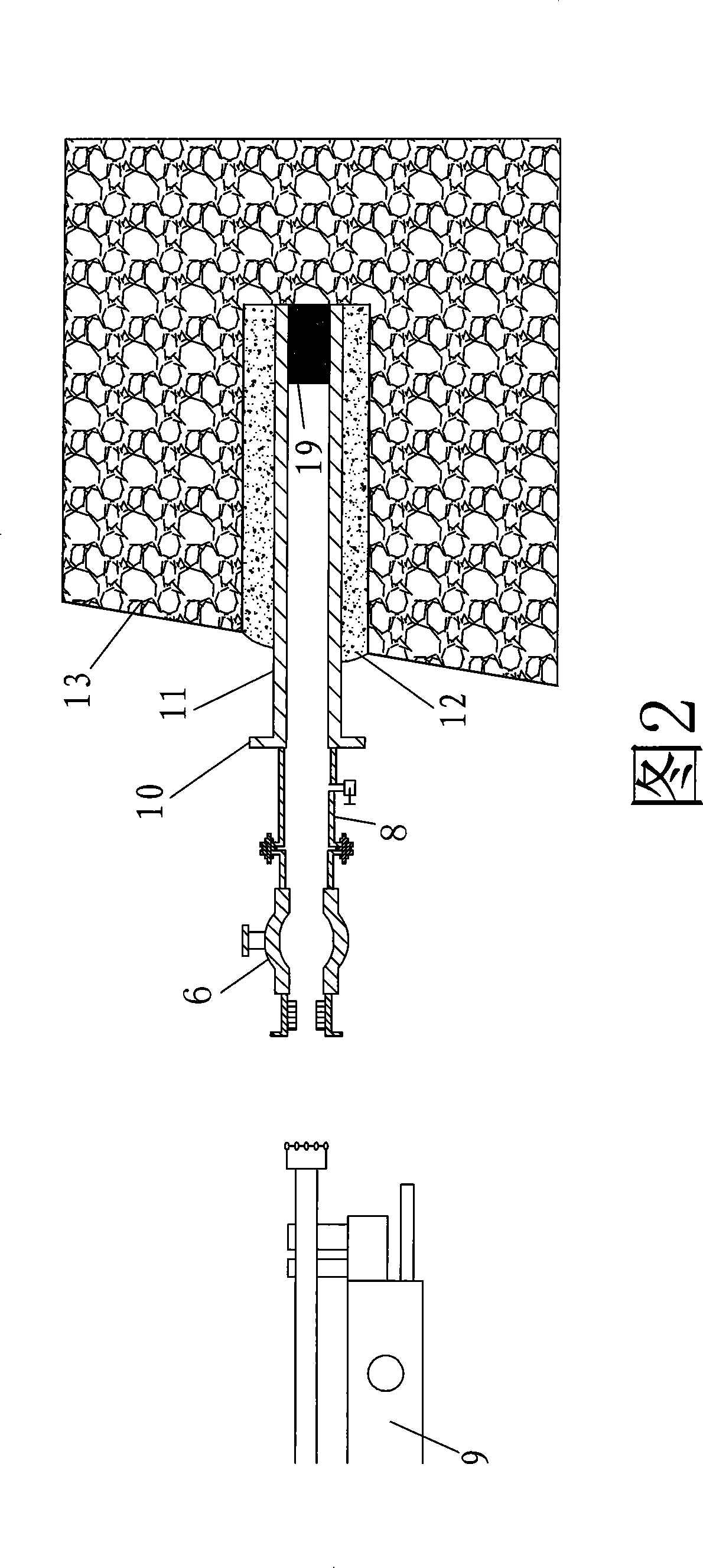

[0012] As shown in FIG. 2 , step 2 is to withdraw the drill pipe and install the orifice pipe 11 , the drainage device 8 and the anti-water inrush device 6 . Orifice pipe 11 adopts seamless steel pipe to process and manufacture, and one end is welded quick connector 10, and the other end is blocked 20cm with cement mortar 19. Before installation, start to wind hemp silk into a spindle shape at a distance of 30 cm from the end of the quick connector at the orifice tube, and put the anchoring agent 12 into the ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com