Expressway underlie warehouse type inclined coal seam goaf comprehensive-treatment method

A highway and comprehensive treatment technology, applied in underground mining, surface mining, earth drilling and mining, etc., can solve the problem of lack of comprehensive and systematic comprehensive treatment methods in the goaf of the underlying storage-type inclined coal seam, and achieve the guarantee of grouting effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

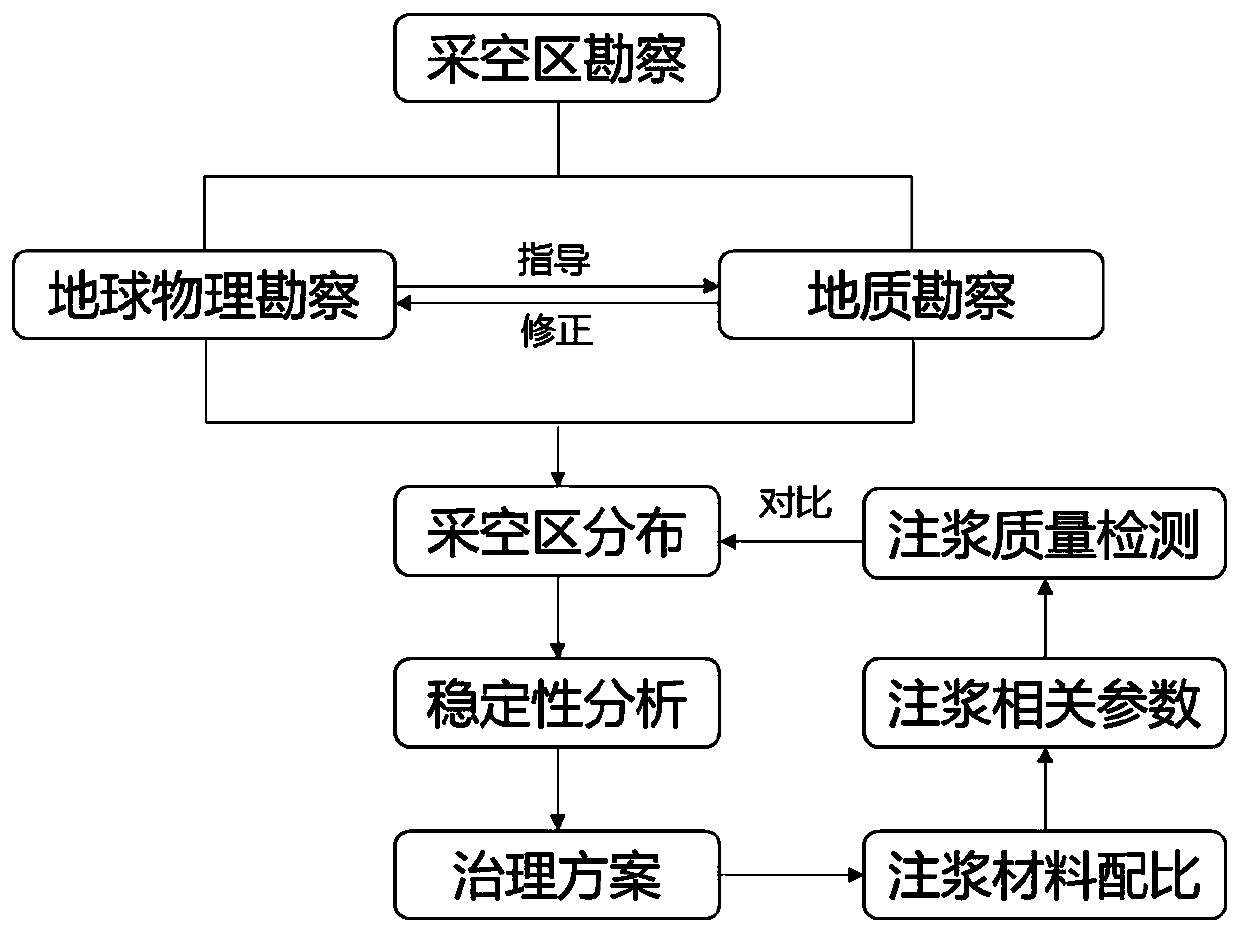

[0075] 1. Gob exploration

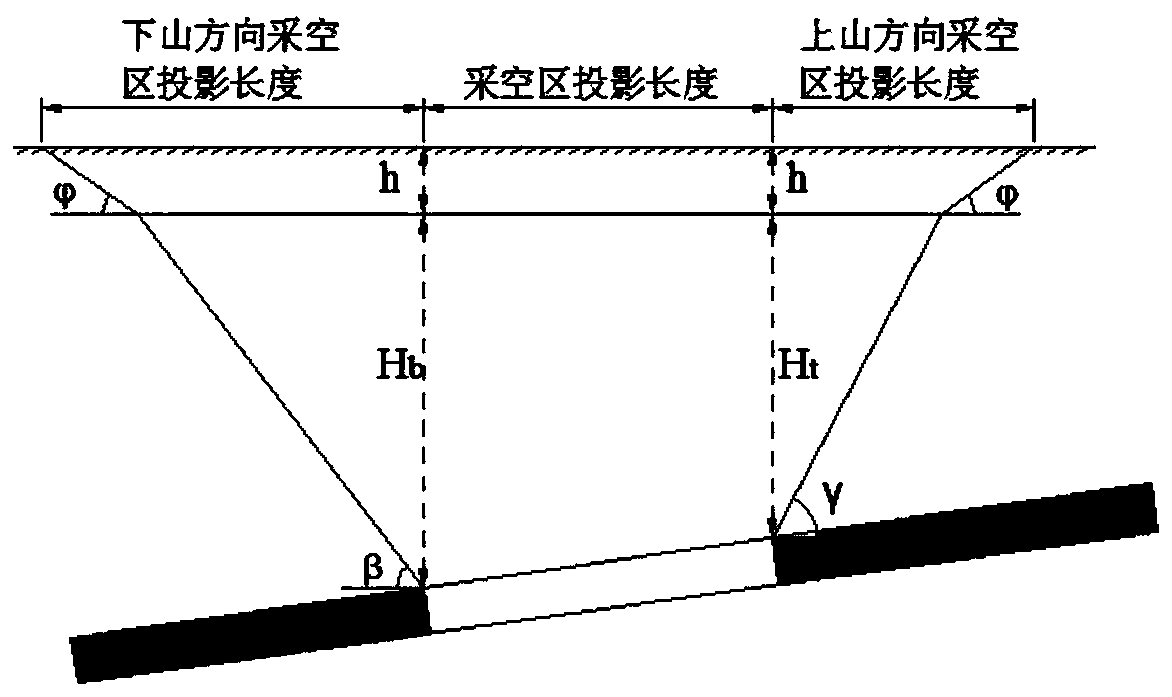

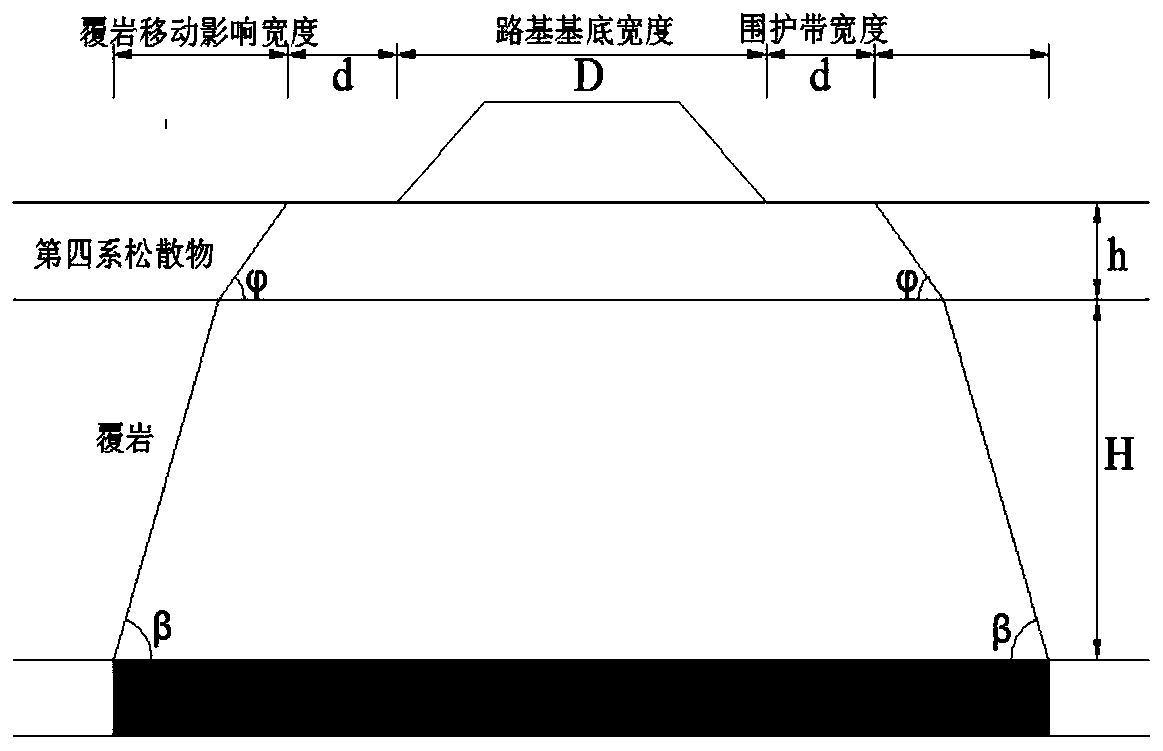

[0076] The well field of a certain mine is 964m long from east to west and 794m wide from north to south, and three coal seams of 42#, 43# and 45# are mined. The mining level of this coal seam is 593-643m, the mining depth is 200-250m, the thickness of the coal seam is 30-40m, the inclination angle of the coal seam is 41-46°, and the mining trend is nearly orthogonal to the line trend (80°-90°). There are relatively large subsidence basins distributed along the coal seam direction on the surface, most of the subsidence basins have been filled up, and the surface has been artificially covered with vegetation. There are many step-like fractures in the north-south direction of the subsidence basin, with a strike of 60-65°. The mining method in this mining area is storage type, which has been stopped.

[0077] At present, geophysical prospecting methods are widely used in gob exploration, and common methods include seismic exploration, geological rada...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com